Manufacturing method of FDY (fully drawn yarn) fine denier differentiation series products

A technology for a series of products and manufacturing methods, applied in the field of chemical fiber product manufacturing, can solve problems such as new product development and weak marketing, and achieve the effect of high social value, broad market prospects, and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 As shown, the manufacturing method of the FDY fine denier differentiated series products described in this example includes the following production steps: polymerization finalizer→melt distributor→booster pump→melt delivery→cooler→static mixer→ Melt distribution valve→spinning box→melt extrusion of metering pump→spinning assembly→circular blower→cooling and forming→oiling with double nozzles→spinning channel→pre-internet→first hot roller→second hot roller→ Main network → wire guide → broken wire detector → winding machine → doffing → dyeing and grading → quality inspection and packaging, in which:

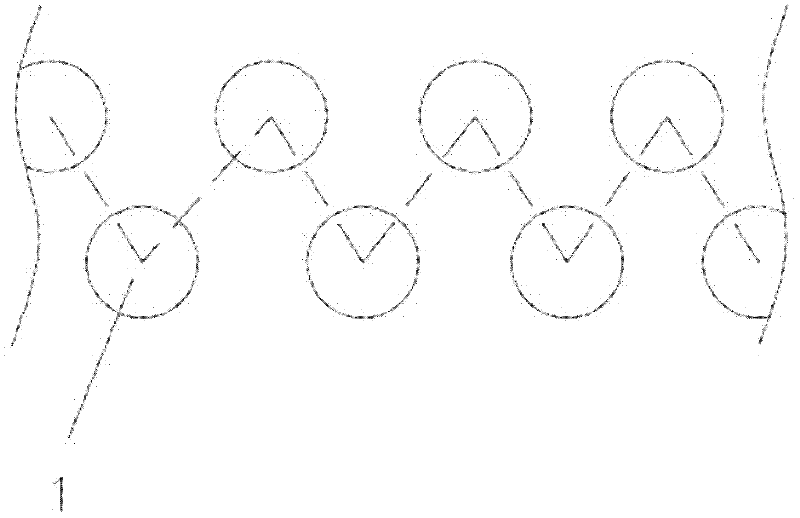

[0032] In the spinning box step, a spinneret with a hole diameter of 0.16 mm and a hole depth of 0.60 mm; a length-to-diameter ratio L / D of 3.75 is used, and the spinnerets are arranged in a W-shaped staggered manner as a whole. Equipped with a heating device, the heating device has a slow cooling effect. By designing the slow cooling heating device, the s...

Embodiment 2

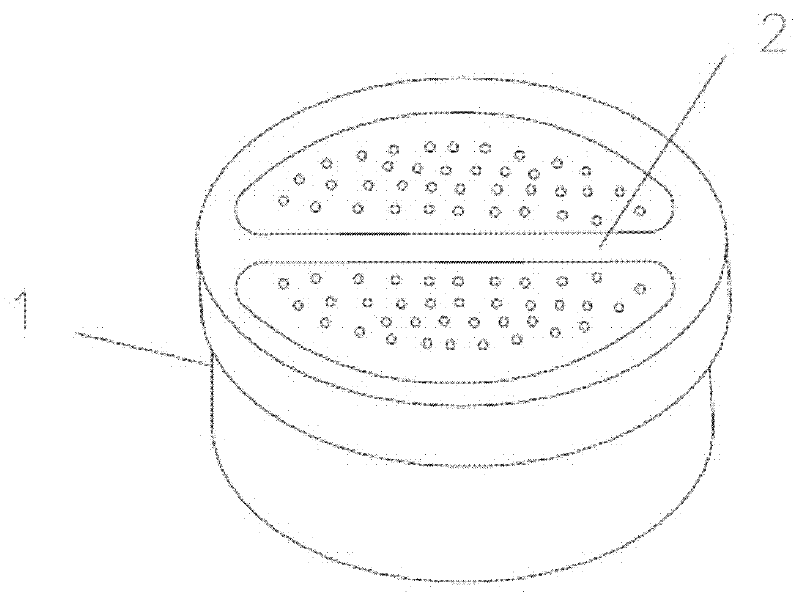

[0065] The manufacturing method of the FDY fine denier differentiated series products described in this embodiment, the spinneret length-to-diameter ratio L / D is 3.56 (0.16 millimeter of hole diameter, 0.57 millimeter of hole depth), and the length of the windless air duct is 60CM, described There is a partition plate in the middle of the spinneret to divide the nozzle hole into two areas. This unique separation technology in the middle of the plate reduces the shear stress of the melt in the spinneret microhole and reduces the melt outlet. Puffing effect, improve spinnability, and achieve the effects of uniform filament separation and uniform cooling; others are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com