Method for forming bonded iron-based powder by high velocity compaction technology

An iron-based powder, high-speed pressing technology, applied in the field of powder metallurgy, can solve problems such as industrial application limitations, and achieve the effect of improving fluidity, uniform alloy composition, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: High-speed compaction of plasticized iron-based powder (Fe-Ni-Cu-C alloy)

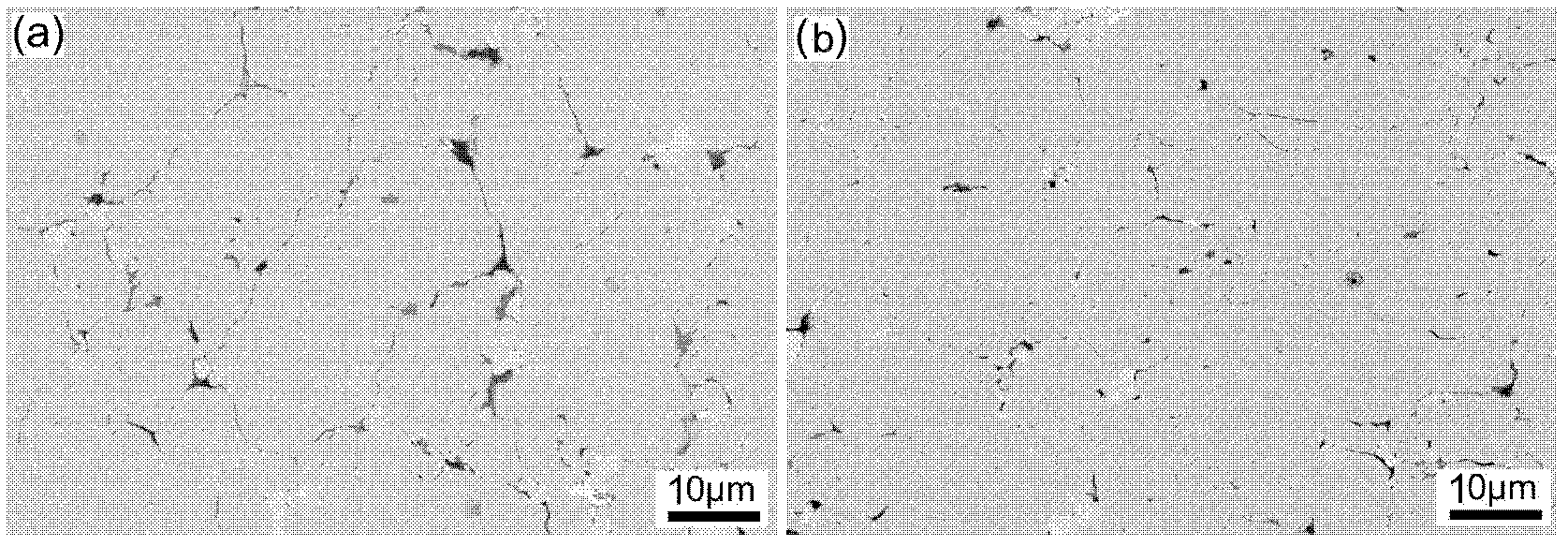

[0021] The nominal composition of the iron-based alloy is Fe-1.5Ni-0.5Cu-0.25C (mass fraction). Water atomized iron powder is used as raw material, and the particle sizes of Ni, Cu and C powders are 2-5 μm, 3-6 μm and 0.5-7 μm respectively. The water atomized iron powder with two particle sizes of coarse and fine is matched, the particle size of the coarse powder is 130-150 μm, the particle size of the fine powder is 50-90 μm, and the mass ratio of the coarse powder to the fine powder is 3:1. According to the particle size matching requirements and the iron-based alloy composition, the alloying element powder is added to the water atomized iron powder, and the pre-mixed uniform mixing time is 3 hours on a planetary ball mill. Then add 0.8wt.% plasticizer to the pre-mixed powder and then carry out caking treatment, and get caking iron-based powder after mixing for 5 hours. The bonded...

Embodiment 2

[0022]Example 2: High speed compaction of plasticized iron-based powder (pure Fe)

[0023] The water atomized iron powder with two particle sizes of coarse and fine is matched, the particle size of the coarse powder is 130-150 μm, the particle size of the fine powder is 50-90 μm, and the mass ratio of the coarse powder to the fine powder is 3:1. Pre-mix the mixed powder with two particle sizes of coarse and fine in a planetary ball mill, and the mixing time is 2 hours. Then 0.4wt.% plasticizer was added to the premixed powder and mixed for 3 hours to obtain cemented iron-based powder. The bonded iron-based powder is plasticized at 750°C in a hydrogen atmosphere, and the heating process is as follows: heating to 200°C at a heating rate of 1°C / min, then holding for 1 hour, and then heating at a heating rate of 5°C / min Heat it to 450°C for 1 hour, and finally heat it to a final temperature of 750°C at a rate of 15°C / min and hold it for 2 hours to obtain plasticized iron-based po...

Embodiment 3

[0024] Example 3: High-speed compaction of plasticized iron-based powder (Fe-P alloy)

[0025] The nominal composition of the iron-based alloy is Fe-0.35wt.%P (mass fraction). Water-atomized iron powder is used as the raw material, and the particle diameters of the iron-phosphorus alloy powder are respectively 4-10 μm. The water-atomized iron powder with two particle sizes of coarse and fine is matched, the particle size of the coarse powder is 130-150 μm, the particle size of the fine powder is 50-90 μm, and the mass ratio of the coarse powder to the fine powder is 4:1. According to the particle size matching requirements and the iron-based alloy composition, the alloy element powder is added to the water atomized iron powder and then pre-mixed evenly on a planetary ball mill. The mixing time is 2 hours. Then, 0.6wt.% plasticizer was added to the premixed powder and mixed for 3 hours, and the heating rate during the plasticizing process was 10°C / min to obtain bonded iron-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com