Automobile radial tire steel cord wet-pulling lubricating agent

A technology for radial tires and wet pull lubricants, applied in the field of fine chemicals, can solve the problems of easy generation of copper soap, metal corrosion, unclean steel wire surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

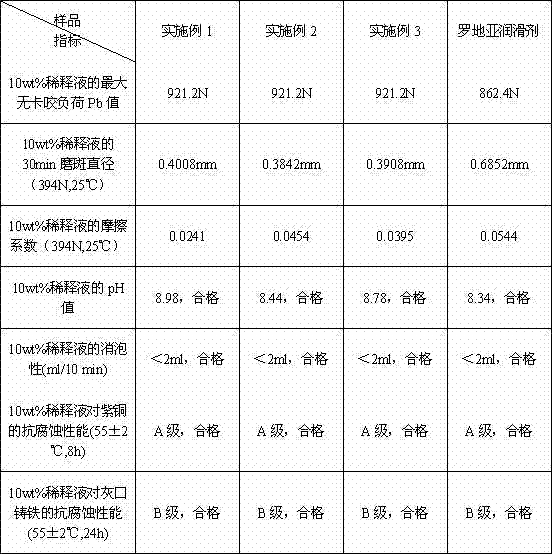

Examples

preparation example Construction

[0028] The preparation method of the lubricant is as follows: dissolve the emulsifier, pH regulator, co-solvent, antirust agent, complexing agent, bactericide, and defoamer in the formula amount into the water of the formula amount and stir vigorously to mix evenly, and then add the formula A certain amount of oily agent and extreme pressure antiwear agent are heated to 50-80°C, vigorously stirred and mixed evenly to obtain the lubricant.

[0029] The use method of the lubricant is as follows: the lubricant is diluted with water to 5-10 wt%, and then added into a bath for wet drawing processing of steel cords of automobile radial tires.

Embodiment 1

[0032] The weight percent of formula is as follows:

[0033] Triethanolamine Oleate Soap: 4

[0034] Triethanolamine oleate: 4

[0035] Oleic acid diethanolamide: 3

[0036] Castor Oil: 2

[0037] Thionium octyl zinc salt (T202): 8

[0038] Pingping plus OS-15: 5

[0039] Triethanolamine: 10

[0040] Glycerin: 7

[0041] Oleic acid diethanolamide borate: 10

[0042] Boric acid: 4

[0043] Benzotriazole: 0.2

[0044] EDTA: 0.1

[0045] Ethylenediamine: 4

[0046] Defoamer: 0.1

[0047] Fungicide: 1

[0048] water: balance

[0049] The main process conditions are: mix all the components and vigorously stir at 80°C for 30 minutes.

Embodiment 2

[0051] The weight percent of formula is as follows:

[0052] Triethanolamine Oleate Soap: 15

[0053] Triethanolamine oleate: 5

[0054] Oleic acid diethanolamide: 5

[0055] Castor Oil: 5

[0056] Thionium octyl zinc salt (T202): 1

[0057] Pingping plus OS-15: 0.5

[0058] Triethanolamine: 3

[0059] Glycerin: 2

[0060] Oleic acid diethanolamide borate: 2

[0061] Boric acid: 1

[0062] Benzotriazole: 0.2

[0063] EDTA: 0.1

[0064] Ethylenediamine: 1

[0065] Defoamer: 0.1

[0066] Fungicide: 1

[0067] water: balance

[0068] The main process conditions are: mix all the components and vigorously stir at 50°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com