Microcrystalline glass containing rare earth mixing yttrium aluminum garnet (YAG) phase and preparation method thereof

A rare earth doped and glass-ceramic technology is applied in the field of rare-earth-doped YAG phase glass-ceramic and its preparation, which can solve the problems of poor optical performance of the glass-ceramic, poor uniformity and dispersibility of rare earth ions, etc. Low cost, good uniformity and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] will analyze pure SiO 2 18mol%, B 2 o 3 37mol%, Na 2 O15mol%, BaO2mol%, K 2 O2mol%, ZnO3mol%, CaO12mol% and Li 2 O11mol% is evenly mixed, poured into a quartz crucible, melted at 980-1000°C, kept warm for 0.2-0.7 hours to fuse into a glass melt, and the glass melt is put into a cast iron mold, and naturally cooled to room temperature to obtain a glass matrix material. The glass matrix material is ground into an average particle size of 200-300 microns for later use; the Al(NO 3 ) 3 solution, Y(NO 3 ) 3 solution and Ce(NO 3 ) 3 solution, according to the general formula (Y 0.97 Ce 0.03 ) 3 Al 5 o 12 The ratio of required Y, Ce and Al molar number is mixed, is made into the total concentration of cation and is 1 liter of mother salt solution of 0.2 mol / liter and puts into the spray container of ultrasonic atomization device, and spray container is connected with ultrasonic spray nozzle; Adjust the pH of the solution with ammonia water to be 10, and put 1 li...

Embodiment 2

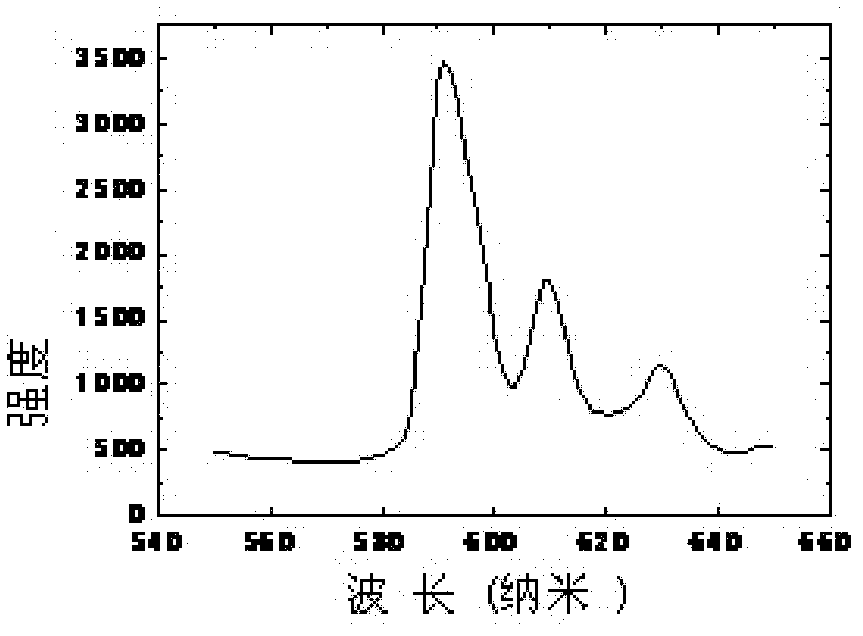

[0023] will analyze pure SiO 2 12mol%, B 2 o 3 50mol%, Na 2 O25mol%, BaO1mol%, K 2 O1mol%, ZnO4mol%, CaO6mol% and Li 2 08mol% mixed evenly, poured into a quartz crucible, melted at 950-980°C, kept warm for 0.8-1.5 hours to fuse into a glass melt, put the glass melt into a cast iron mold, and naturally cooled to room temperature to obtain a glass matrix material. The glass matrix material is ground into an average particle size of 100-200 microns for later use; the Al(NO 3 ) 3 solution, Y(NO 3 ) 3 solution and Eu(Cl) 3 solution, according to the general formula (Y 0.92 Eu 0.08 ) 3 Al 5 o 12 The ratio of required Y, Eu and Al molar number is mixed, is made into the mother salt solution that total concentration of cation is 0.3 mol / liter and is put into the spray container of ultrasonic atomization device, and spray container is connected with ultrasonic spray head; Concentration is The 0.9 mol / liter ammonium bicarbonate solution is adjusted to the pH of the solutio...

Embodiment 3

[0025] will analyze pure SiO 2 43mol%, B 2 o 3 20mol%, Na 2 O6mol%, BaO5mol%, K 2 O5mol%, ZnO13mol%, CaO24mol% and Li 2 Mix O22mol% evenly, put it into a quartz crucible, melt it at 920-950°C, keep it warm for 1.5-2.0 hours and fuse it into a glass melt, put the glass melt into a cast iron mold, and cool it naturally to room temperature to obtain a glass matrix material. The glass matrix material is ground into an average particle size of not more than 300 microns for later use; the Al(NO 3 ) 3 solution, Y(NO 3 ) 3 solution and Nd (NO 3 ) 3 solution, according to the general formula (Y 0.95 Nd 0.05 ) 3 Al 5 o 12 The ratio of required Y, Nd and Al molar number is mixed, is made into the mother salt solution that total concentration of cation is 0.15 mol / liter and puts into the spray container of ultrasonic atomization device, and spray container is connected with ultrasonic spray head; Concentration is 0.45 mol / liter of ammonium bicarbonate solution is adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com