Method and system for preparing soft water and utilizing afterheat by using spent steam obtained through ironmaking blast furnace slag washing

A technology of ironmaking blast furnace and slag flushing, which is applied in the field of waste heat utilization, can solve the problems of fast scaling of heat exchangers and pipes, poor heating effect, etc., achieve the effects of reducing dust emissions, reducing the amount of recycled wastewater, and improving the quality of effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

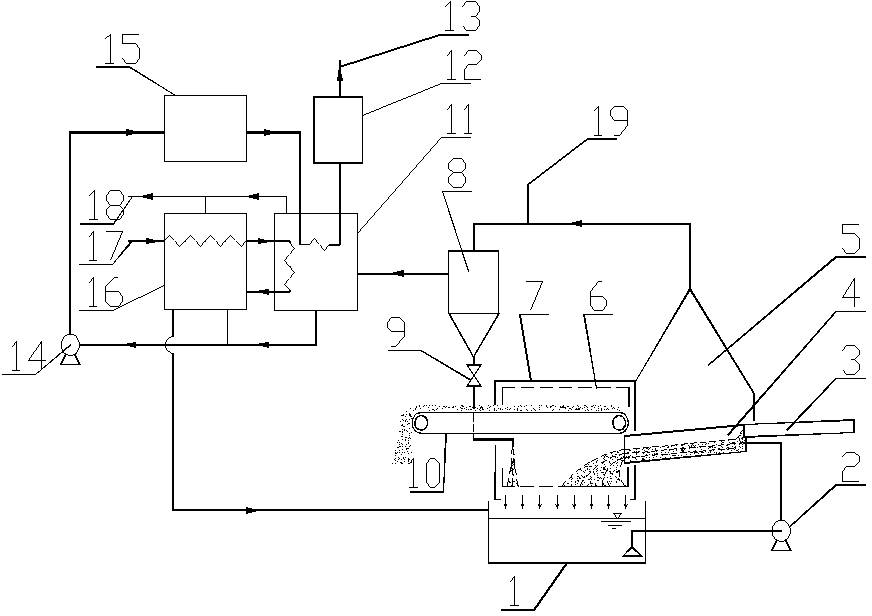

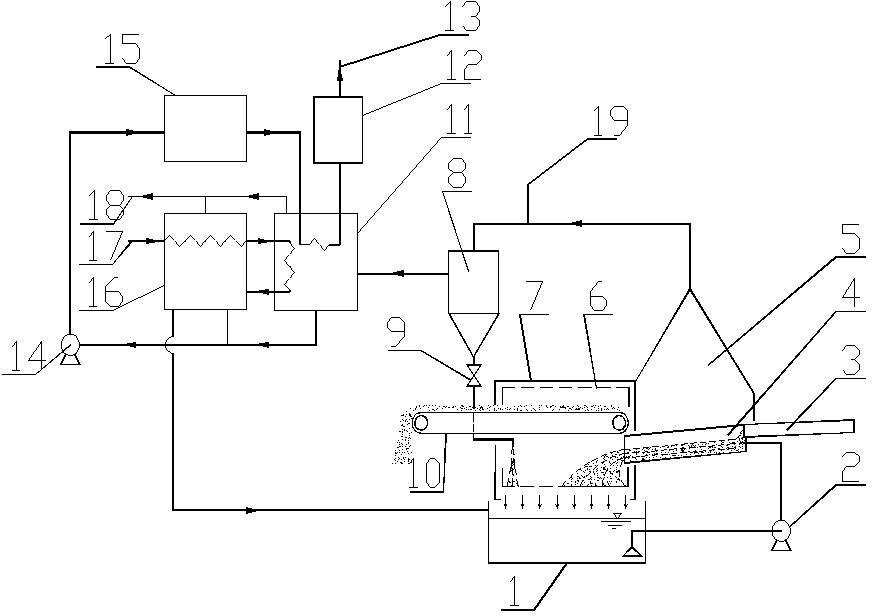

[0012] The present invention is described in detail below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, the present invention is a system for preparing soft water from slag flushing waste steam of ironmaking blast furnace and utilizing waste heat. It is composed of three parts: water quenching cycle slag flushing device, waste steam purification device and water production device. The main structure and function of each part are introduced. as follows:

[0014] Part 1: Water quenching cycle slag flushing device

[0015] The high temperature slag ditch 3 is set above the inlet of the slag flushing tank 4, and the outlet pipe from the slag flushing water circulation pump 2 is connected directly below the outlet of the high temperature slag ditch 3, so that the discharged high temperature slag is dispersed by the high-speed water flow below and cooled rapidly granulation, the slag water falls into the slag washing tank 4; the slag washing tank 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com