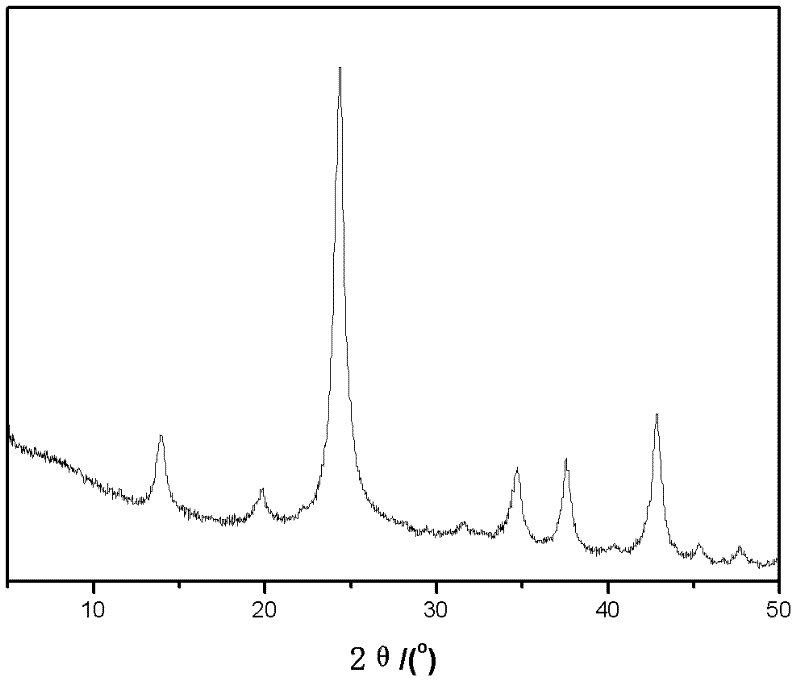

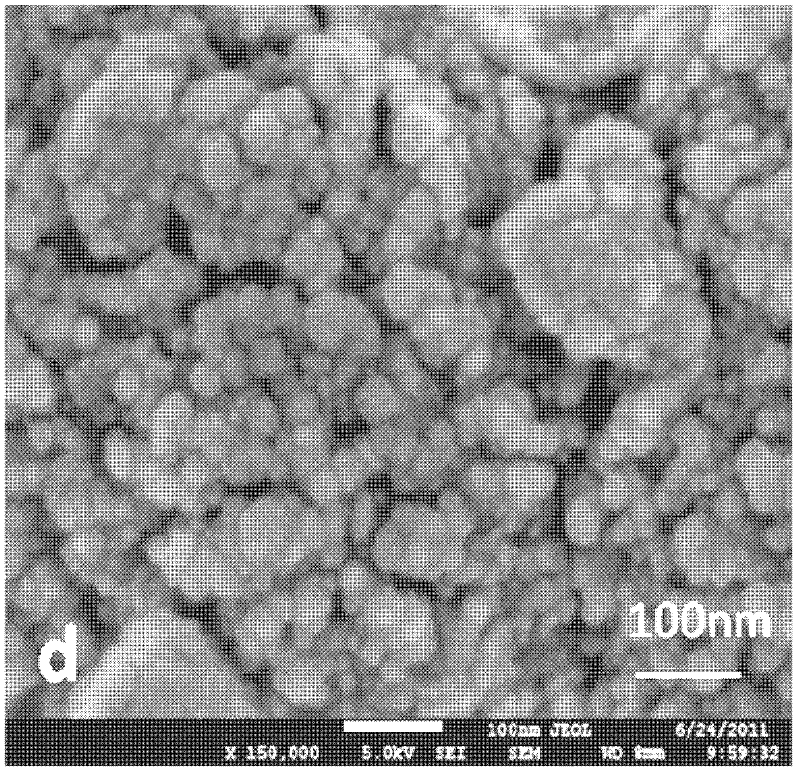

Preparation method of nanometer sodalite powder

A technology of stone powder and nanometer, which is applied in the field of preparation of nanosodalite powder, to achieve the effect of improving efficiency, narrow particle size distribution and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 1.42g Na 2 SiO 3 9H 2 O, 0.32g NaOH and 0.784g KOH are added in the beaker, then add 8.5g deionized water, and heat to make the raw materials dissolve rapidly and completely, and make solution A;

[0041] (2) Weigh 0.3g NaAlO 2 Add it to another beaker, then add 10g of deionized water, and heat to dissolve the raw materials quickly and completely to make solution B;

[0042] (3) Slowly add solution A to solution B, and stir rapidly to make it mix evenly to form a silica-alumina gel;

[0043] (4) Add 22.5 g of ionic liquid to the prepared silica-alumina gel, and then stir for 1 to 4 hours to form a crystallization precursor;

[0044] (5) Put the beaker containing the above-mentioned crystallization precursor solution into a microwave reactor, set the temperature to 70°C, the stirring speed to 600r / min and the reaction time to 90 minutes, and then start to crystallize;

[0045] (6) After the reaction is completed, take out the beaker, cool the reactant, and p...

Embodiment 2

[0047] (1) Weigh 3.2gNa 2 SiO 3 9H 2 Add O, 0.32NaOH and 0.784KOH into the beaker, then add 10g of deionized water, and heat to dissolve the raw materials quickly and completely to make solution A;

[0048] (2) Weigh 0.9g NaAlO 2 Add it to another beaker, add 11g of deionized water, and heat to dissolve the raw materials quickly and completely to make solution B;

[0049] (3) Slowly add solution A to solution B, and stir rapidly to make it mix evenly to form a silica gel;

[0050] (4) Add 32.5 g of ionic liquid to the prepared silica-alumina gel, and then stir for 1 to 4 hours to form a crystallization precursor;

[0051] (5) Put the beaker containing the above-mentioned crystallization precursor liquid into a microwave reactor, set the temperature at 60°C, the stirring speed at 700r / min and the reaction time for 105 minutes, and then start crystallization;

[0052] (6) After the reaction is completed, take out the beaker, cool the reactant, and perform suction filtration...

Embodiment 3

[0054] (1) Weigh 5.5gNa 2 SiO 3 9H 2 Add O, 0.32NaOH and 0.784KOH into the beaker, then add 14g of deionized water, and heat to dissolve the raw materials quickly and completely to make solution A;

[0055] (2) Weigh 1.9g NaAlO 2 Add it to another beaker, then add 14g deionized water, and heat to dissolve the raw materials quickly and completely to make solution B;

[0056] (3) Slowly add solution A to solution B, and stir rapidly to make it mix evenly to form a silica gel;

[0057] (4) Add 46.5 g of ionic liquid to the prepared silica-alumina gel, and then stir for 1 to 4 hours to form a crystallization precursor;

[0058] (5) Put the beaker containing the above-mentioned crystallization precursor solution into a microwave reactor, set the temperature to 90°C, the stirring speed to 400r / min and the reaction time to 60 minutes, and then start to crystallize;

[0059] (6) After the reaction is completed, take out the beaker, cool the reactant, and perform suction filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com