rotary tool

A technology of rotating tools and rotating bodies, which is applied in the direction of manufacturing tools, metal processing equipment, and cutting tools of sawing machines, and can solve problems such as easy burrs at the corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

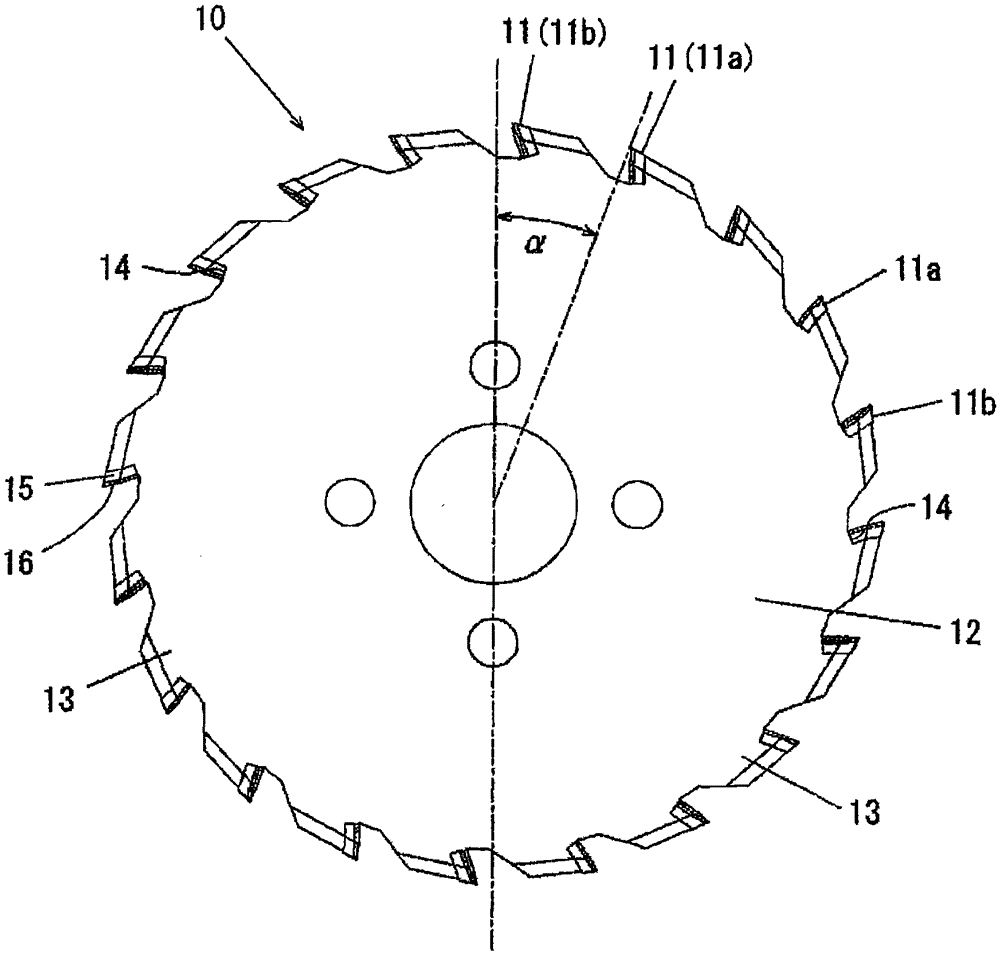

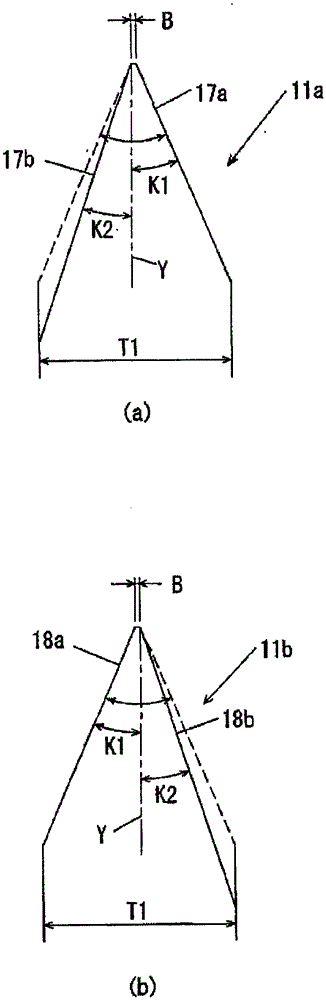

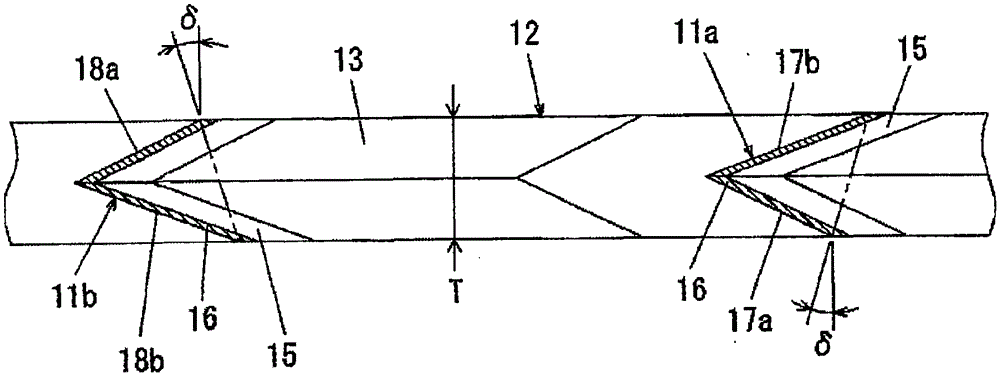

[0085] Hereinafter, the form for implementing this invention is concretely demonstrated based on drawing. Such as figure 1 , figure 2 As shown, the rotary tool 10 according to the first embodiment of the present invention is a rotary tool having inverted V-shaped pieces 11 (11a, 11b) on the outer periphery of a disk-shaped rotary body (base member) 12 along the circumferential direction. Serrated edge lands 13 are formed at equal intervals. The blade base 13 is formed in an inverted V-shape when viewed from the front, and a mounting portion 14 notched into an L-shape when viewed from the side is formed on the side of the rotation direction surface of the blade base 13 , and an inverted V-shape is fixed to the mounting portion 14 . Sheet 11 (11a, 11b). The inverted V-shaped piece 11 has a polycrystalline diamond layer (PCD layer) 16 on the front side of the cemented carbide layer 15, and the PCD layer 16 is placed on the mounting part 14 toward the side of the rotation dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com