Edge extrusion riveting mold of solar energy heat radiation base plate

A technology of heat dissipation base plate and heat dissipation base, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient supply of solar heat dissipation base plate, large size of solar heat dissipation base plate, influence retention and thermal conductivity, etc. Product manufacturing competitiveness, widening market share, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

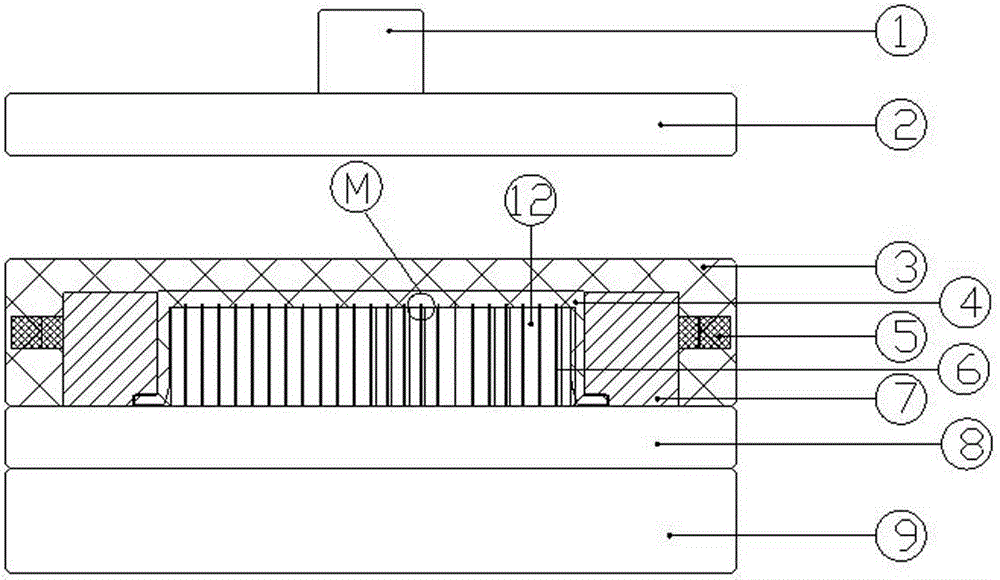

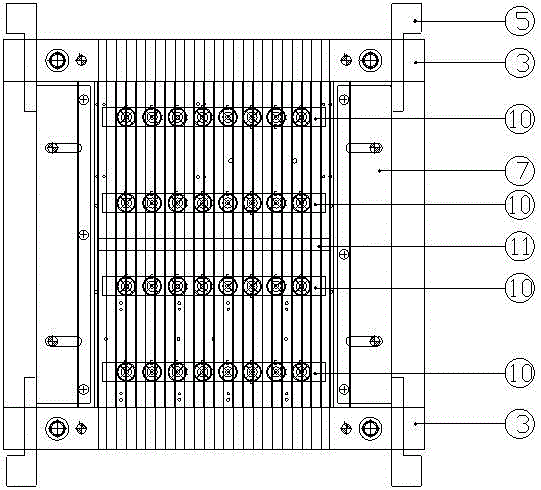

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

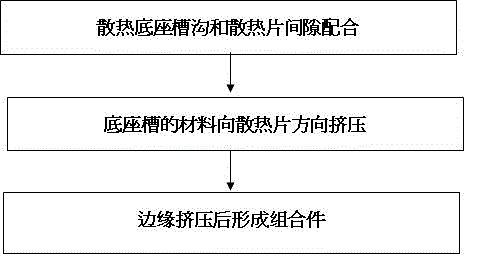

[0020] See Figure 1 to Figure 4 This embodiment provides an edge extrusion and riveting process for the combined production of heat sinks with strong holding force, stable quality, low cost, uniform contact surface and good thermal conductivity. The heat sink to be combined in this embodiment The bottom plate includes a heat dissipation base 4 and a plurality of heat dissipation fins 6 arranged in the heat dissipation base 4. The heat dissipation base 4 is processed with grooves 41 for installing the heat dissipation fins 4; during assembly and assembly, the edge extrusion and riveting process steps are as follows:

[0021] First, place the heat sink 6 in the groove 41 of the heat dissipation base 4, and match the gap between the groove 41 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com