Technique and device for dry formation of low basis weight fluff pulp and capable of eliminating electrostatic flocculation

A technology for dry forming and eliminating static electricity, used in textiles and papermaking, papermaking machines, tobacco, etc., can solve the problems of difficult quantification, high fiber loss, unsuitable for reconstituted tobacco control and raw material standard requirements, etc., to achieve uniformity improvement, The effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

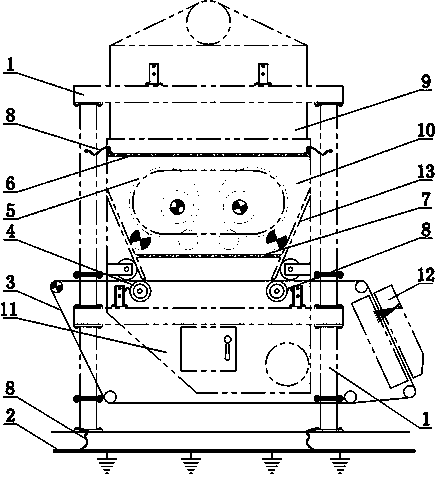

[0011] Explanation of symbols in the attached drawings: Attached figure 1 ~ attached figure 2 Middle, 1—frame, 2—independent grounding grid, 3—ribbed metal mesh, 4—supporting roller, 5—cylindrical screen, 6—upper grounding grid, 7—lower grounding grid, 8—copper braid, 9— Air supply device, 10—forming box, 11—vacuum box, 12—screen washing device, 13—slope plate.

[0012] Embodiments of the present invention are further described below in conjunction with the accompanying drawings: figure 1 , The low-quantity fluff pulp dry-forming technology and device that can eliminate electrostatic flocculation disclosed by the present invention is a low-quantity fluff pulp dry-forming and electrostatic flocculation elimination technology suitable for a quantitative range of 15-30g / ㎡, combined with a static elimination device , to produce the fluff pulp fiber bottom layer of reconstituted tobacco leaves, including frame 1, cylindrical screen 5, forming net 3, inclined plate 13, idler rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com