Method for decreasing warp and bow of silicon carbide wafer

A bending and warping technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as epitaxial growth inconvenience, wafer cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

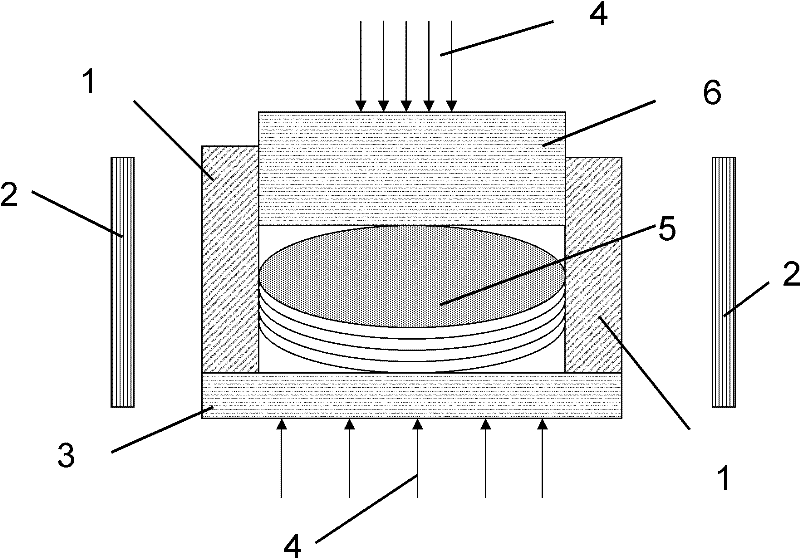

[0024] Such as figure 1 As shown, take 5 pieces of 3inch wafers that have been ground and polished, and put them between the upper platen 6 and the lower platen 6; Among them, it is required that the surfaces of the upper platen 6 and the lower platen 3 in contact with the wafer are very flat, and the warpage and curvature are all controlled to be less than 1um. Chips are stacked on top of each other and placed in figure 1 5 positions marked. Then, a pressure 4 of about 50Kg is applied on the upper and lower platens, so that the wafer is deformed flatly according to the surface shape of the platens. At the same time, the system is heated by the heater 2, and the temperature at the wafer is controlled at 1500° C. (measured by a thermocouple). After holding for 10 hours, the temperature of the wafer was gradually lowered to room temperature over 5 hours. The warpage and curvature of the wafer are measured by flatness testing equipment. The curvature Bow of the 5 wafers befor...

Embodiment 2

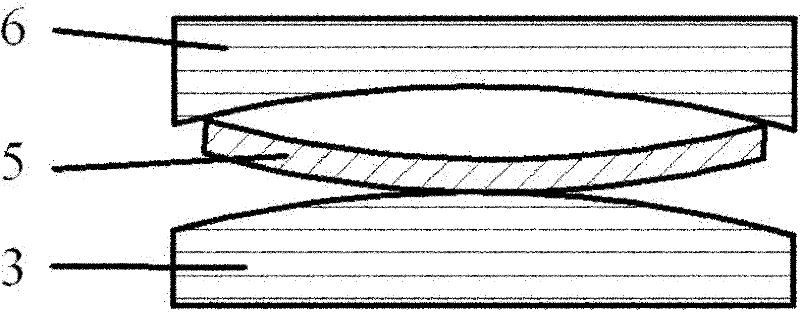

[0026] Take a 3inch wafer that has been ground and polished, such as figure 2 As shown, it is loaded between the upper platen 6 and the lower platen 6; Among them, it is required that the surfaces of the upper platen 6 and the lower platen 3 in contact with the wafer have a surface opposite to the warping of the wafer, and the warpage and curvature are all controlled at about 5um. chip placed in figure 2 5 positions marked. Then, a pressure of about 10Kg is applied on the upper and lower platens, so that the wafer is deformed in opposite directions according to the surface shape of the platens. At the same time, by heating the system, the temperature at the wafer is controlled at 1000°C (the temperature is measured with a thermocouple). After holding for 2 hours, the temperature of the wafer was gradually lowered to room temperature over 1 hour. The warpage and curvature of the wafer are measured by flatness testing equipment. The curvature Bow of the wafer before treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com