Flowmeter sensor based on electromagnetic correlation method

A flowmeter and related method technology, applied in the field of sensors, can solve the problems of small influence of measurement results, high content of non-conductive substances, and large influence of measurement results, and achieves low manufacturing cost, wide flow measurement range, and increased measurement. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

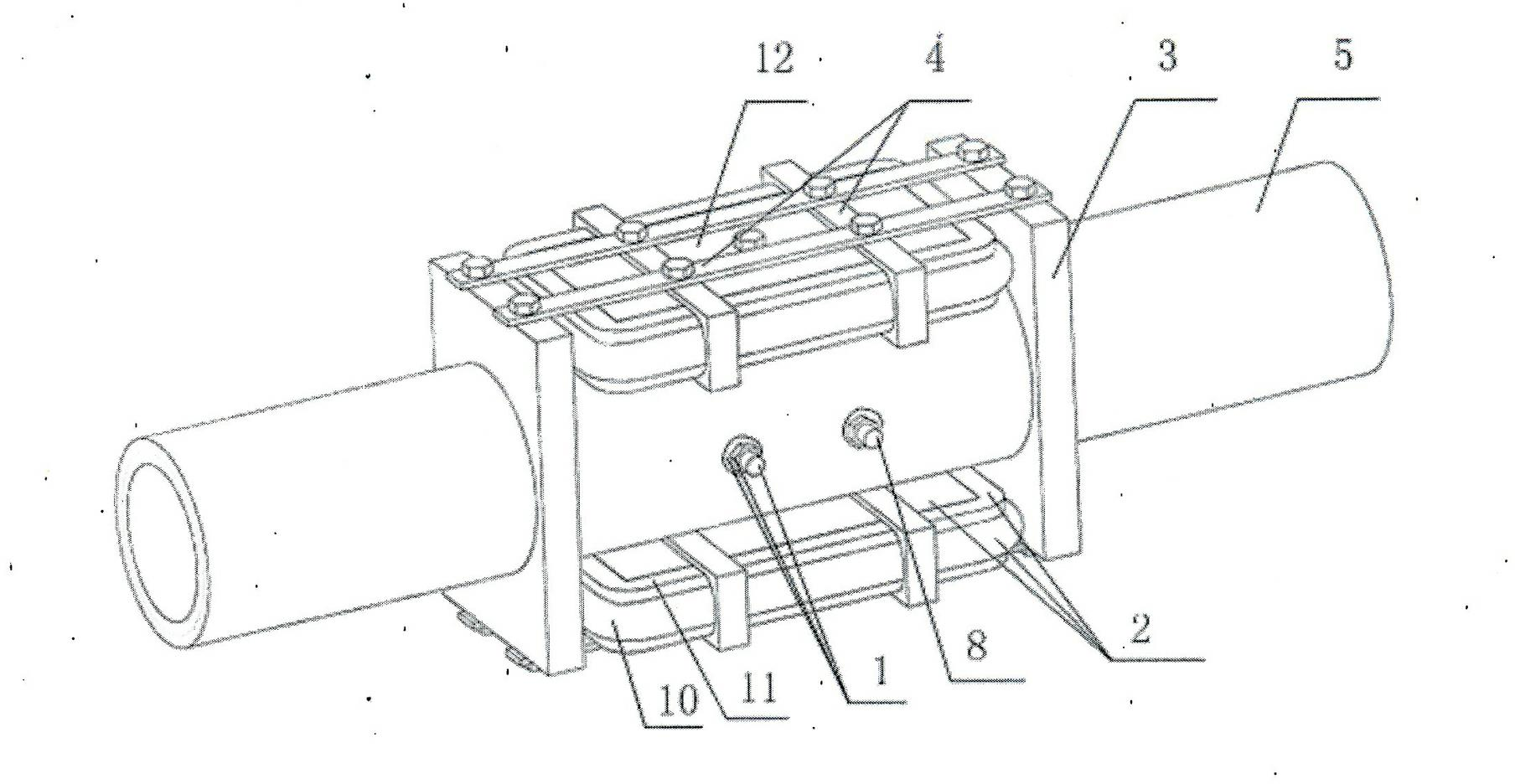

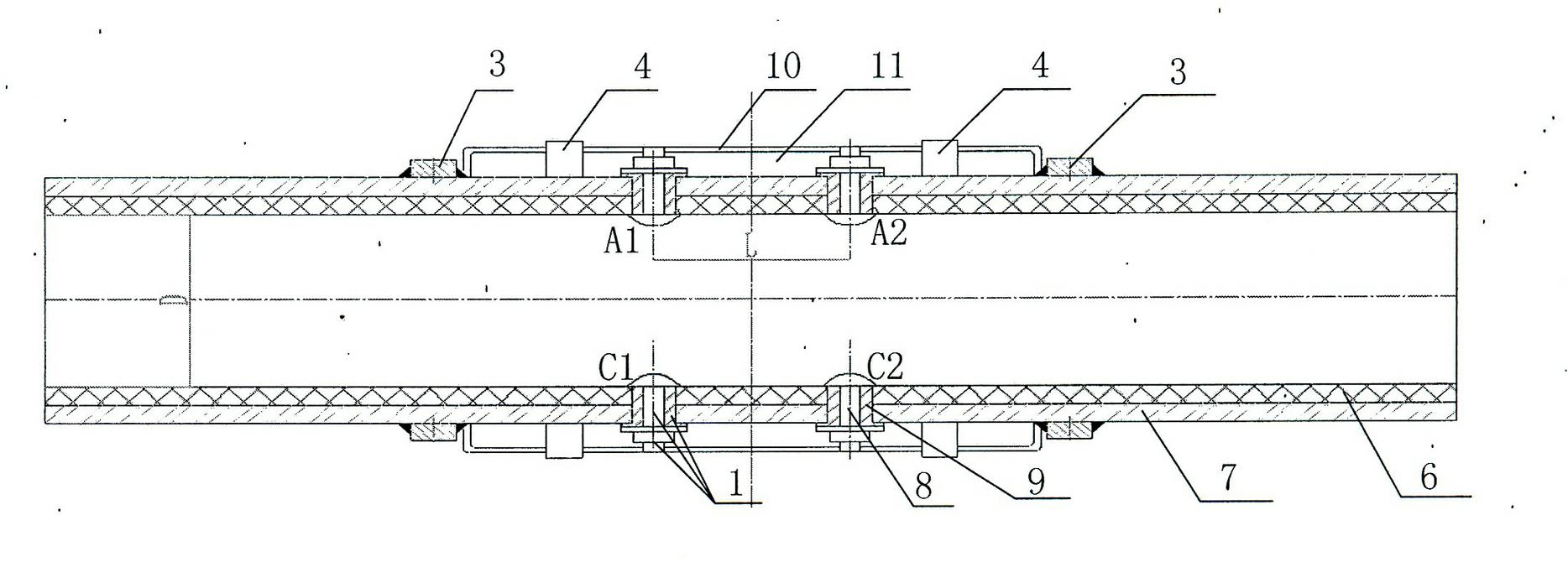

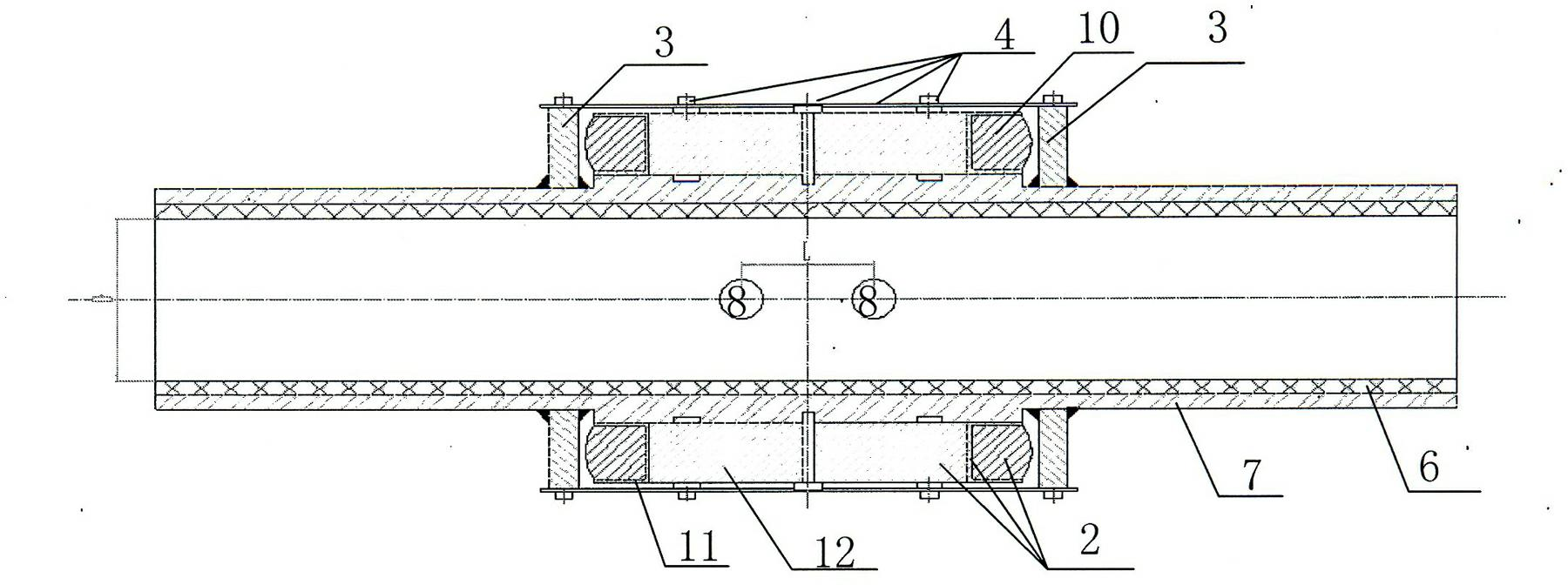

[0021] An electromagnetic correlation method flowmeter sensor, such as figure 1 — Figure 4 As shown, the sensor includes two pairs of measuring electrode assemblies 1, a pair of excitation structure assemblies 2, a pair of fixed frame plates 3 with holes and an excitation structure installation device 4, and the fixed frame plates 3 with holes are respectively set on the outside of the measuring pipe 5 , and fixed on the measuring pipe 5, the plate surfaces of the fixing frame plates 3 are parallel to each other and form an angle of 90 degrees with the axial direction of the measuring pipe; the measuring pipe 5 is composed of the lining 6 and the measuring pipe wall 7; The two sides of the measuring pipe 5 are placed in parallel, and are fixed on the fixing frame plate 3 with holes through the excitation structure installation device 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com