Method and device for drying by heating and dehydrating

A heating dehydration and drying technology, which is applied in the direction of heating to dry solid materials, drying solid materials, drying gas arrangement, etc., to achieve good energy saving effect, improve color and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

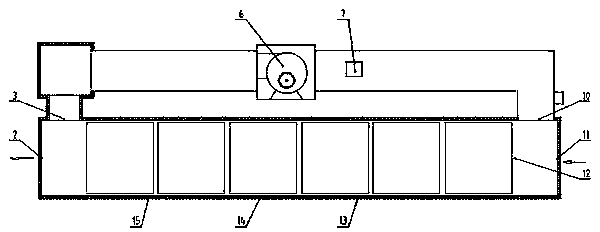

[0038] The heating dehydration drying device of the present invention, its structure sees figure 1 , including drying tunnel 12;

[0039] The feed port 11 and the discharge port 2 are respectively arranged at both ends of the drying tunnel 12, the feed port 11 in this embodiment is arranged at the right end of the drying tunnel 12, and the feed port 2 is arranged at the The left end of the drying tunnel 12; the hot air inlet 3 and the air outlet and humidity discharge port 10; the hot air inlet 3 is one or more, and is arranged on the side of the discharge port 2. In this embodiment, there is one hot air inlet 3, and the The air outlet and humidity discharge port 10 is arranged on the side of the feed port 11 .

[0040] As a preferred embodiment, a fan 6 is connected to the hot air inlet 3 , and the fan 6 is also connected to the air outlet and humidity outlet 10 . Further, a hot air replenishment port 7 is also provided on the pipe connecting the fan 6 and the air outlet a...

Embodiment 2

[0042] In the heating dehydration drying device described in Example 1 of the present invention, the temperature drop in the tunnel changes with the change of the tunnel length 12. In this embodiment, the length of the drying tunnel 12 is set to 60 meters, and the temperature drop is 0.5°C / m .

Embodiment 3

[0044] In the heating dehydration drying device described in Example 1 of the present invention, the length of the drying tunnel 12 is set to be 10 meters, and the temperature drop is 3°C / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com