Waste heat recovering device for conduction oil furnace

A technology of waste heat recovery device and heat conduction oil furnace, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of not meeting the requirements of energy saving and environmental protection, and low thermal efficiency of boilers, and achieve flexible and convenient layout, high waste heat recovery rate, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

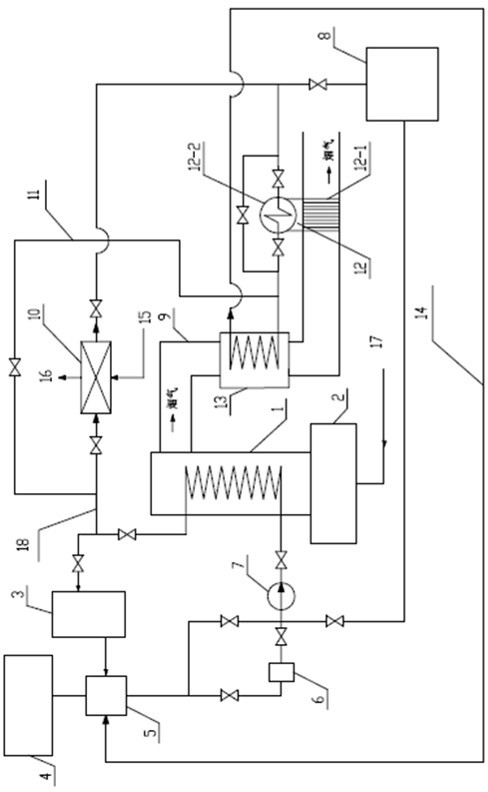

Embodiment 1

[0035] attached image 3 It is a schematic flow chart of an embodiment of the structure of the heat-conducting oil furnace tail gas waste heat recovery device of the present invention, wherein the heat-conducting oil furnace includes a furnace body 1, a heating source 2, a flue 9 and a high-temperature end heat-conducting oil circulation circuit, and the heating source 2 can be coal or oil. or gas as fuel. The heat transfer oil circulation loop at the high temperature end includes heat-using equipment 3, oil-gas separator 5, filter 6, hot oil pump 7, high-level expansion tank 4, low-level oil storage tank 8, and supporting pipelines, valves and control instruments, etc. The heat transfer oil circulation loop at the high temperature end of the present invention is as follows: the heat transfer oil enters the furnace body 1 after being pressurized by the heat oil pump 7 to absorb the heat generated by combustion, and then enters the heat oil pump after passing through the heat u...

Embodiment 2

[0043] Another embodiment of the present invention is: the outlet of the heat transfer oil internal circulation pipeline 18 is between the outlet of the heat oil pump 7 and the oil inlet pipeline of the furnace body 1, and the rest of the implementation is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com