Waterproof construction method characterized by heat pipeline sleeved in steel sleeve pre-buried in external wall and waterproof system structure using for same

A technology for thermal pipelines and construction methods, applied in the direction of pipes/pipe joints/fittings, pipes, machinery and equipment, etc., can solve the problems of long custom-made processing cycle, complicated on-site construction, high construction cost, and achieve good waterproof effect, simple construction, The effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

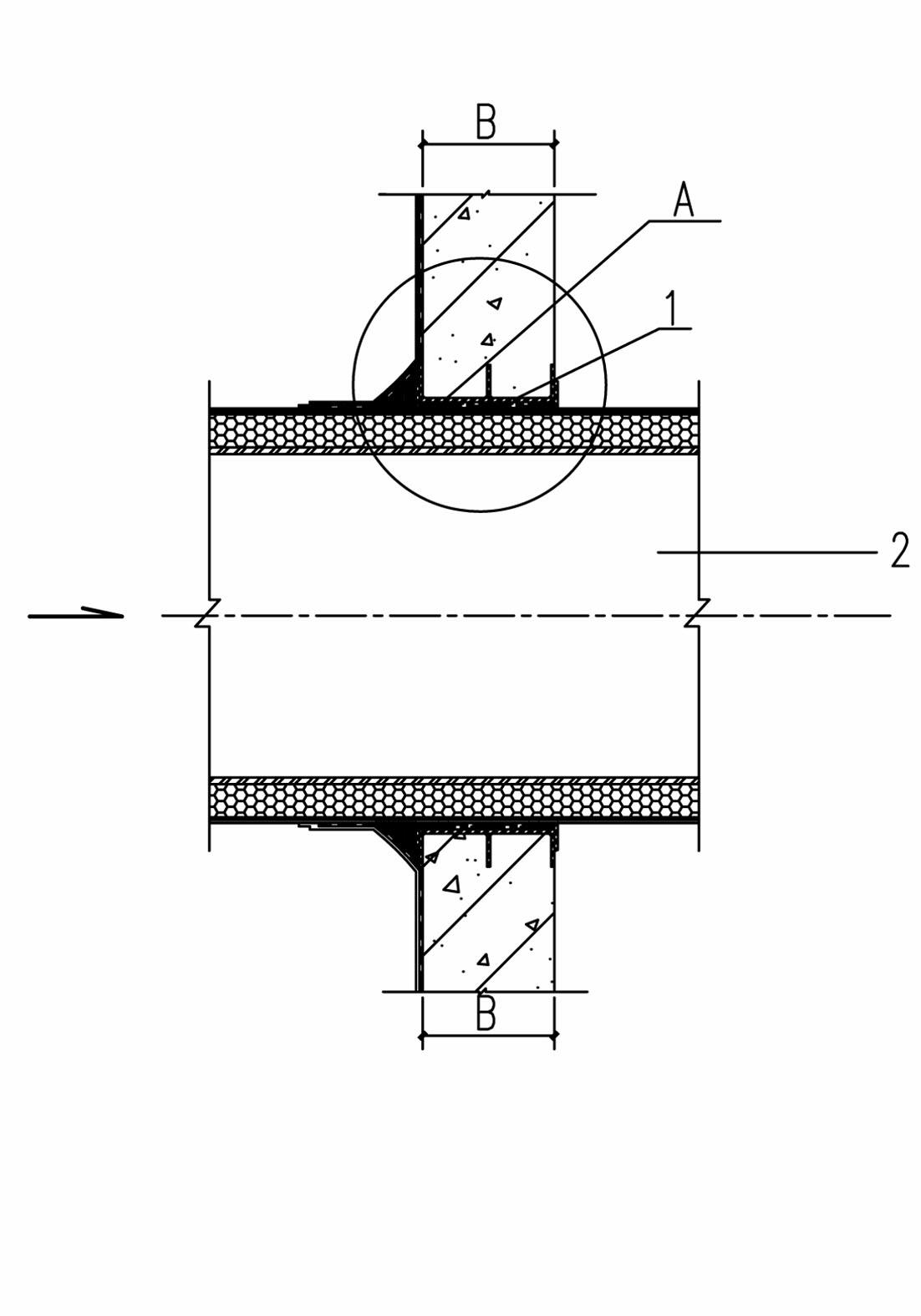

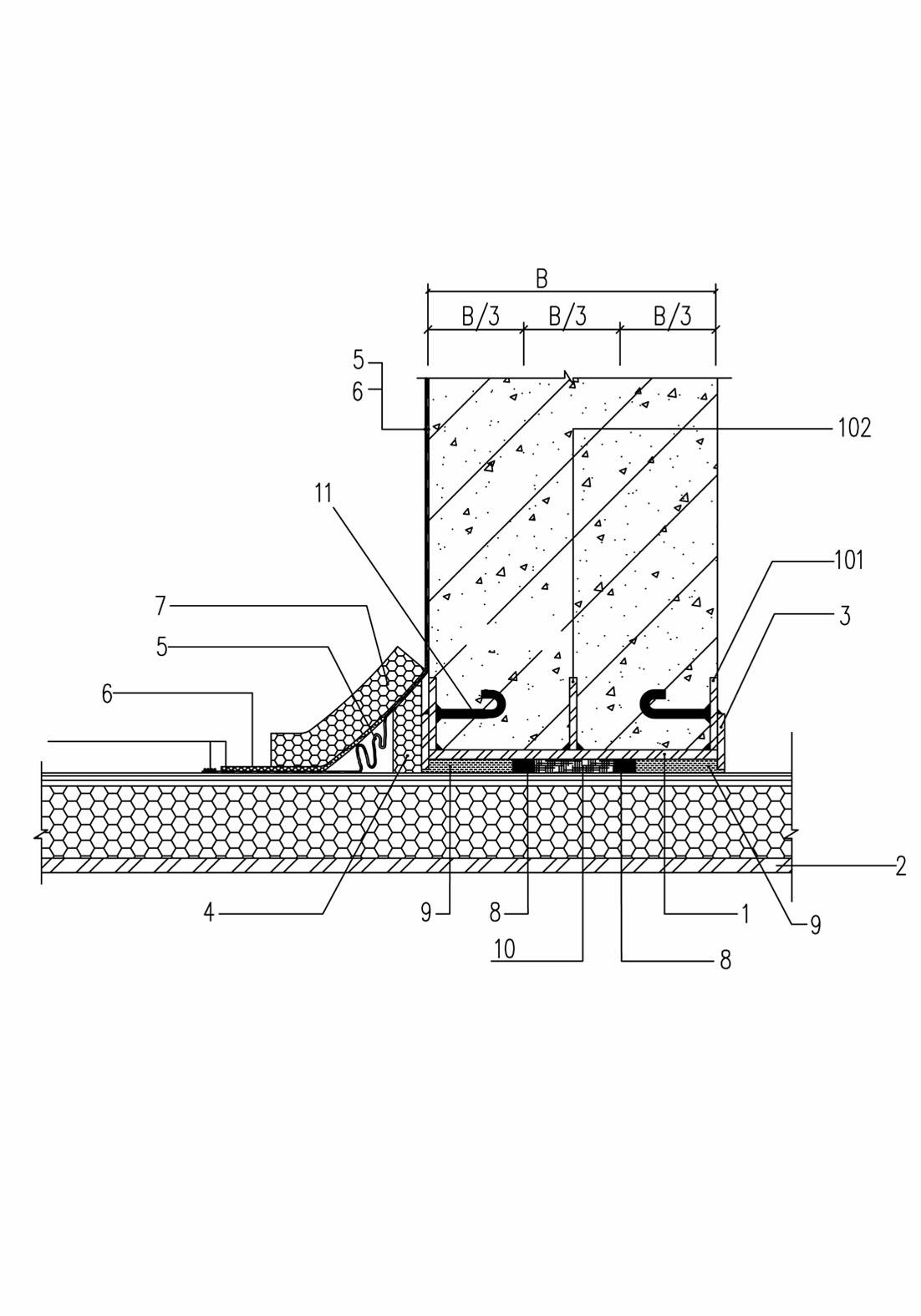

[0050] like figure 1 , figure 2 As shown, the pre-design is used in a central heating pipe network project in a riverside city. Directly buried DN1000 large-diameter thermal main line, located in the Songhua River Basin, with high groundwater level, underground pipeline equipment valve room has waterproof requirements, the specific steps of the waterproof construction method of directly buried thermal pipeline through the wall:

[0051] 1. The processing factory customizes the pre-embedded steel casing DN1330X12, and processes the annular water-stop flange -100X10, -100X10 wing ring at the same time, and the length of the steel casing 1 is processed according to the thickness B of the side wall of the equipment valve chamber;

[0052] 2. The finished steel casing is pre-embedded in a fixed position on the side wall of the reinforced concrete equipment valve chamber;

[0053] 3. The directly buried thermal insulation pipeline 2 passes through the steel casing 1 and is instal...

Embodiment 2

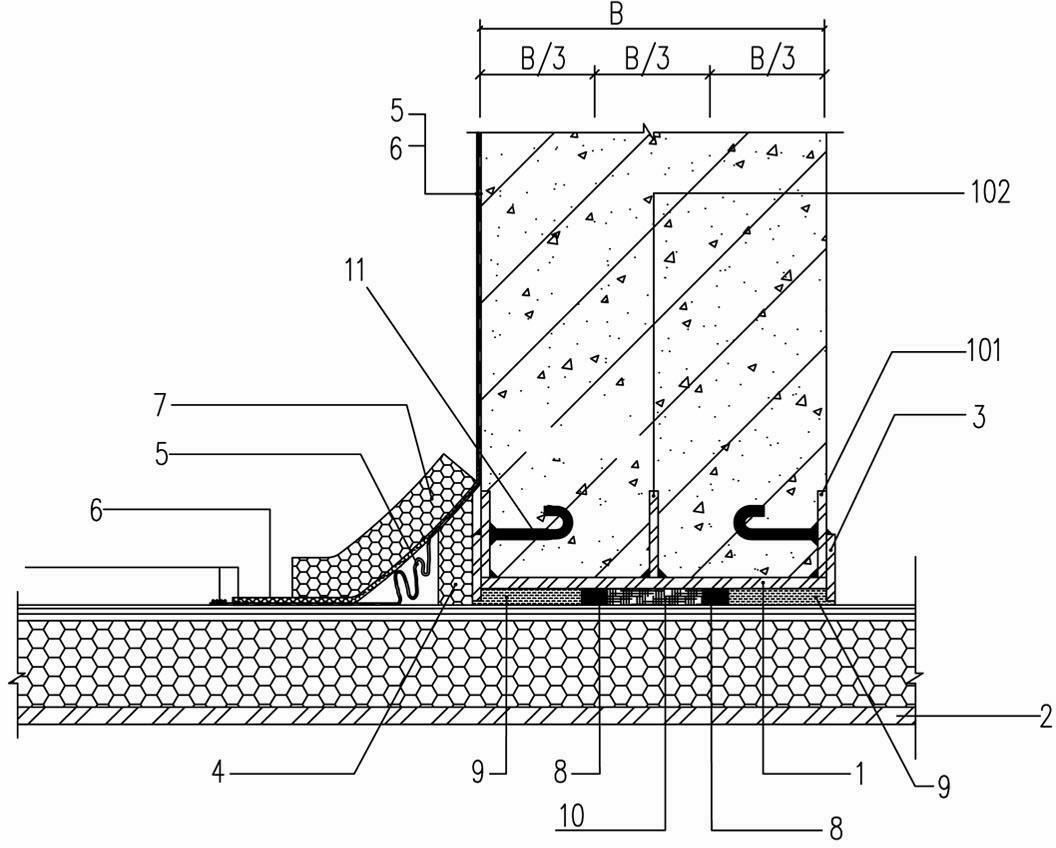

[0060] The thermal main line is directly buried with a large pipe diameter of DN1000, and the waterproof construction method of the thermal pipeline through the wall is similar to Example 1. The difference is: the waterproof treatment of the outer corner of the thermal insulation pipeline and the side wall of the valve chamber:

[0061] The steel casing is pre-embedded on the outer wall of the valve, and the extruded polystyrene board is pasted as a cushion. The outer wall is waterproof along the cushion and makes three to five folds within 200mm of the corner to keep the waterproof membrane loose and along the heat After the insulation pipe is waterproofed to 200mm, the waterproof coiled material is firmly bonded to the outer wall of the direct-buried thermal insulation pipe and wrapped tightly with glass cloth;

[0062] 5mm polyethylene sheet is used for protection on the outside of the waterproof membrane, and another 20mm polyethylene sheet is used to tighten the loose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com