Device for repairing electrolytic aluminium anode steel claw by total cross-section fusion welding

An electrolytic aluminum anode, full-section technology, applied in the field of repair equipment, to achieve the effects of eliminating severe heating, accurate appearance and size control, and high repair accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

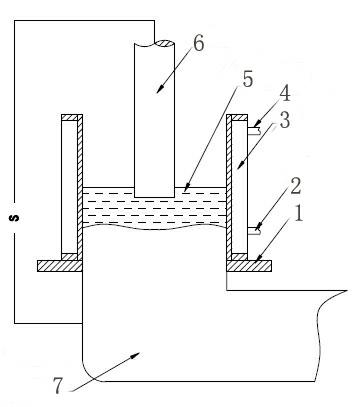

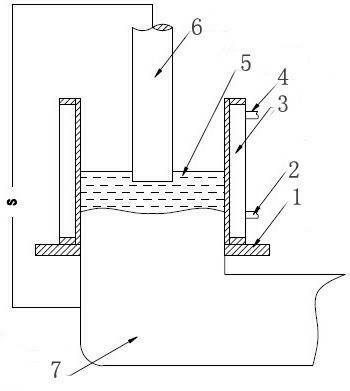

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings: full-section welding and repairing electrolytic aluminum anode steel claw equipment, which is characterized in that: the cavity formed by the metal tray 1, the mold 3 and the residual steel claw leg 7 forms a slag pool, so The metal tray 1 is placed on two opposite sides of the residual steel claw legs 7, and the mold 3 is placed on the metal tray 1 and closely fits with the residual steel claw legs 7; the mold 3 is connected up and down to the water outlet pipe 4 and the water inlet pipe 2 respectively And the inside of the mold 3 is a cavity; the flux 5 is placed in the slag pool; the electrode 6 is inserted into the slag pool and kept at a certain distance from the residual steel claw leg 7; the electrode 6 and the residual steel claw leg 7 are connected to the transformer through wires .

[0018] The process of repairing electrolytic aluminum anode steel cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com