Ultrapure smelting method of low-alloy high-strength steel

A low-alloy high-strength, pure technology, applied in the field of vacuum induction melting, can solve the problem of inability to achieve ultra-pure, and achieve the effect of improving hot working performance, improving service performance, and reducing ductile-brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

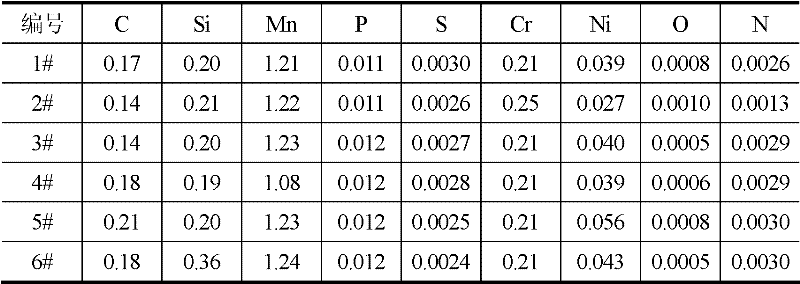

Examples

Embodiment 1

[0025] Use high-purity, thermodynamically stable CaO crucible to melt low-alloy high-strength steel. The melting process includes: charging → melting period → refining period → condensation → deoxidation, desulfurization period → pouring; among them, charging, melting period, pouring Using conventional techniques. The specific process is:

[0026] (1) 50kg CaO forming crucible for smelting crucible, CaO purity ≥ 98.5wt%;

[0027] (2) Alloy raw materials: According to the composition requirements, the constituent elements of steel such as industrial pure Fe, polysilicon, metal manganese and metal chromium, as well as deoxidizing and desulfurizing agents.

[0028] In this step, the deoxidizing and desulfurizing agent is a Si-Ca master alloy: Si: 25wt%, Ca 75wt%.

[0029] (3) Alloy charging: put the main raw materials Fe, Cr, and Si into the crucible, and put Mn and deoxidizing and desulfurizing agents into different compartments of the alloy feeding hopper;

[0030] (4) Alloy...

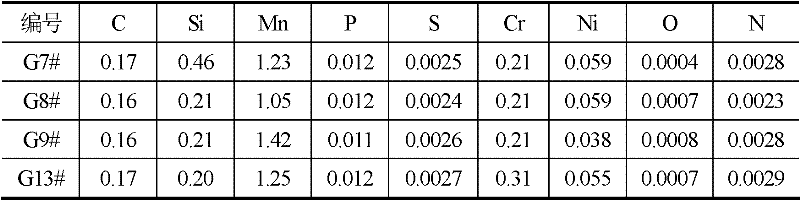

Embodiment 2

[0040] Use high-purity, thermodynamically stable CaO crucible to melt low-alloy high-strength steel. The melting process includes: charging → melting period → refining period → condensation → deoxidation, desulfurization period → pouring; among them, charging, melting period, pouring Using conventional techniques. The specific process is:

[0041] (1) 50kg CaO forming crucible for smelting crucible, CaO purity ≥ 98.5wt%;

[0042] (2) Alloy raw materials: According to the composition requirements, the constituent elements of steel such as industrial pure Fe, polysilicon, metal manganese and metal chromium, as well as deoxidizing and desulfurizing agents.

[0043] In this step, the deoxidizing and desulfurizing agents are Si-Ca master alloys: Si: 25wt%, Ca: 75wt%.

[0044] (3) Alloy charging: put the main raw materials Fe, Cr, and Si into the crucible, and put Mn and deoxidizing and desulfurizing agents into different compartments of the alloy feeding hopper;

[0045] (4) All...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com