Nano wax emulsion

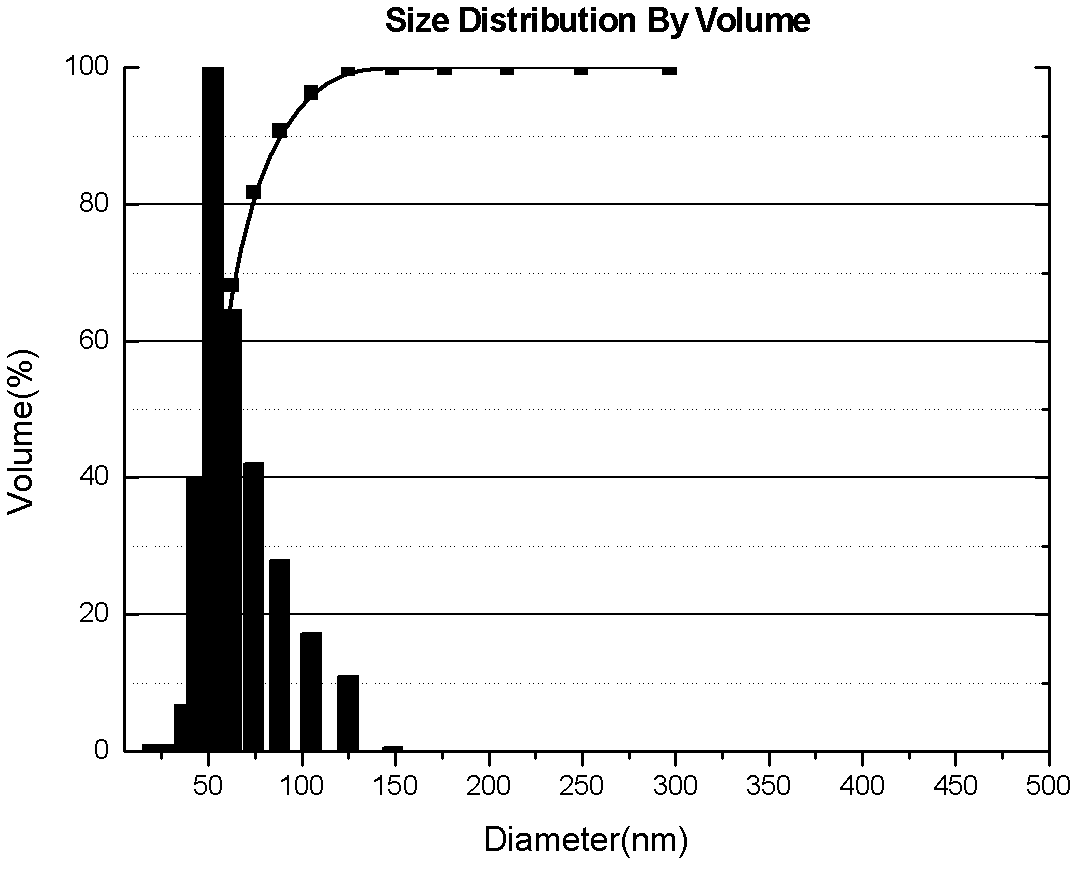

A wax emulsion and nano technology, applied in the field of wax emulsion preparation, can solve the problems of inability to reach nano-scale emulsion, reduced use efficiency, uneven dispersion, etc., and achieve narrow particle size distribution, reduce addition amount, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] see figure 1 , the present invention also provides the preparation method of above-mentioned nano-wax emulsion, comprises the steps:

[0054] (1) Oil phase dispersion mixture:

[0055] Add measured polyethylene wax, montan wax, polyethylene oxide and co-solvent to the high-pressure reaction kettle in sequence to heat and melt, set the heating temperature at about 110-120°C, stir at a speed of 100-200rpm, and stir for 0.5-1.0h , to make it completely dissolve; keep the temperature constant, under low-speed stirring (stirring speed 100-200rpm), add metered ionic emulsifiers and non-ionic emulsifiers to the reaction kettle in turn to make them uniformly dispersed in the wax. Oil phase dispersion mixture.

[0056] (2) Water phase dispersion mixture:

[0057] Put the weighed deionized water, diffusing agent, and stabilizer into the emulsification reaction kettle in sequence, set the temperature at 95-100°C and rotate at 200-300rpm to dissolve and heat up, and stir for 0.5...

Embodiment 1

[0063] Accurately weigh 28.50% polyethylene wax, 9.50% montan wax, 1.00% polyethylene oxide and 0.45% co-solvent (propylene glycol) into the autoclave in sequence, heat up to melt at about 110-120°C, and stir at a speed of 100- 200rpm, stirring time 0.5-1.0h, to make it completely dissolved; under constant temperature and low-speed stirring (stirring speed 100-200rpm), add metered ionic emulsifier (sodium dodecylbenzenesulfonate) to the reaction kettle in sequence 2.65% and non-ionic emulsifier (stearic acid monoglyceride) 3.12%, so that it is uniformly dispersed in the wax to obtain a uniform oil phase dispersion mixture;

[0064] Add 19.00% of the weighed deionized water, 0.70% of the diffusing agent (sodium methylene bis-naphthalene sulfonate) and 0.068% of the stabilizer (stearic acid) into the emulsification reaction kettle in sequence, and set the temperature at about 95-100°C Under the condition of 200-300rpm and rotating speed, dissolve and heat up, and stir for 0.5-1....

Embodiment 2

[0068] Accurately weigh 28.00% of polyethylene wax, 14.00% of montan wax, 0.80% of polyethylene oxide and 0.35% of co-solvent (polyethylene glycol) into the autoclave in sequence, heat up to melt at about 110-120°C, and stir The speed is 100-200rpm, and the stirring time is 0.5-1.0h to make it completely dissolved; under constant temperature and low-speed stirring (stirring speed 100-200rpm), add the measured ionic emulsifier (hexadecyl trimethyl ammonium chloride) 2.40% and non-ionic emulsifier (nonylphenol polyoxyethylene ether) 4.30% to make it uniformly dispersed in the wax to obtain a uniform oil phase dispersion mixture;

[0069] Add 25.20% of the weighed deionized water, 0.70% of the diffusing agent (sodium lignin sulfonate) and 0.068% of the stabilizer (potassium stearate) into the emulsification reaction kettle in sequence, set the temperature at about 95-100°C and the speed Under the condition of 200-300rpm, dissolve and heat up, and stir for 0.5-1.5h to prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com