Nano wax emulsion and preparation method for nano wax emulsion

A wax emulsion and nanotechnology, applied in the field of high melting point and high solid content nano wax emulsion and its preparation, can solve the problems of inability to reach nano-scale emulsion, reduced use efficiency, uneven dispersion and the like, and achieve narrow particle size distribution, Reduce the amount of addition, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

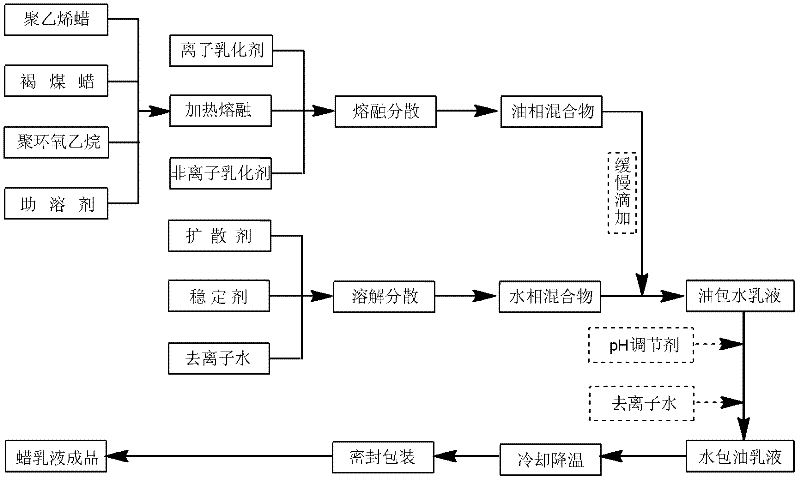

[0053] see figure 1 , the present invention also provides the preparation method of above-mentioned nano-wax emulsion, comprises the steps:

[0054] (1) Oil phase dispersion mixture:

[0055] Add measured polyethylene wax, montan wax, polyethylene oxide and co-solvent to the high-pressure reaction kettle in sequence to heat and melt, set the heating temperature at about 110-120°C, stir at a speed of 100-200rpm, and stir for 0.5-1.0h , to make it dissolve completely; keep the temperature constant, under low-speed stirring (stirring speed 100-200rpm), sequentially add metered ionic emulsifier and non-ionic emulsifier to the reaction kettle to make it uniformly dispersed in the wax to obtain uniform dispersion Oil phase dispersion mixture.

[0056] (2) Water phase dispersion mixture:

[0057] Put the weighed deionized water, diffusing agent, and stabilizer into the emulsification reaction kettle in sequence, set the temperature at 95-100°C and rotate at 200-300rpm to dissolve ...

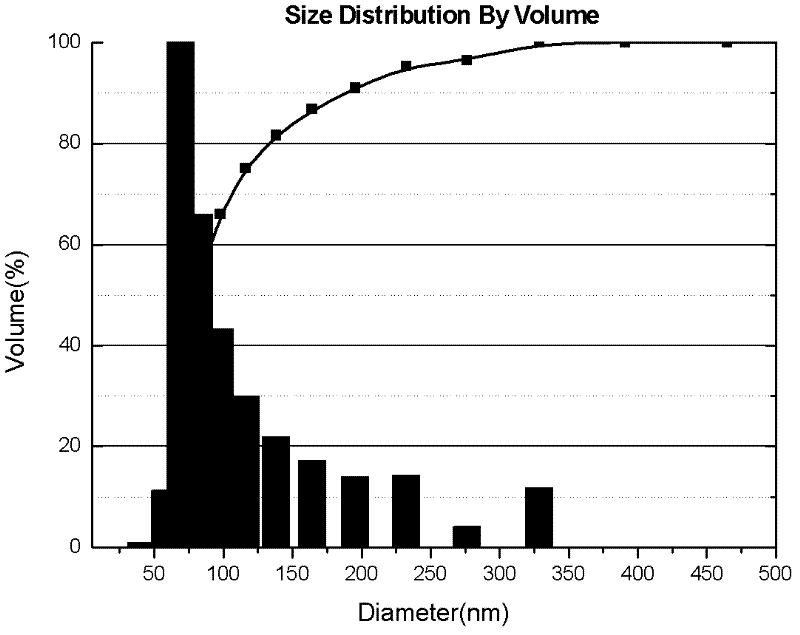

Embodiment 1

[0063] Accurately weigh 28.50% of polyethylene wax, 9.50% of montan wax, 1.00% of polyethylene oxide and 0.45% of cosolvent (propylene glycol) into the autoclave in turn, heat up to melt at about 110-120°C, and stir at a speed of 100- 200rpm, stirring time 0.5-1.0h, to make it completely dissolved; under constant temperature and low-speed stirring (stirring speed 100-200rpm), add metered ionic emulsifier (sodium dodecylbenzenesulfonate) to the reaction kettle in sequence 2.65% and nonionic emulsifier (stearic acid monoglyceride) 3.12%, so that it is uniformly dispersed in the wax to obtain a uniform oil phase dispersion mixture;

[0064] Add 19.00% of the weighed deionized water, 0.70% of the diffusing agent (sodium methylene bis-naphthalene sulfonate) and 0.068% of the stabilizer (stearic acid) into the emulsification reaction kettle in sequence, and set the temperature at about 95-100°C Under the condition of 200-300rpm and rotating speed, dissolve and heat up, and stir for ...

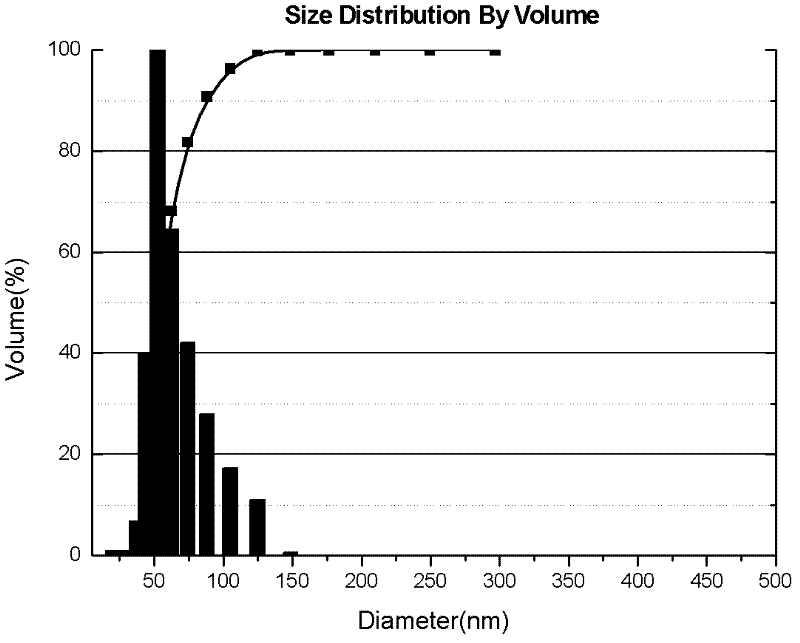

Embodiment 2

[0068] Accurately weigh 28.00% of polyethylene wax, 14.00% of montan wax, 0.80% of polyethylene oxide and 0.35% of cosolvent (polyethylene glycol) into the autoclave in sequence, heat up to melt at about 110-120°C, stir The speed is 100-200rpm, and the stirring time is 0.5-1.0h to make it dissolve completely; under constant temperature and low-speed stirring (stirring speed 100-200rpm), add metered ionic emulsifier (hexadecyl trimethyl ammonium chloride) 2.40% and nonionic emulsifier (nonylphenol polyoxyethylene ether) 4.30% to make it uniformly dispersed in the wax to obtain a uniform oil phase dispersion mixture;

[0069] Add 25.20% of the weighed deionized water, 0.70% of the diffusing agent (sodium lignin sulfonate) and 0.068% of the stabilizer (potassium stearate) into the emulsification reaction kettle in sequence, set the temperature at about 95-100°C and the rotation speed Under the condition of 200-300rpm, dissolve and heat up, and stir for 0.5-1.5h to prepare the aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com