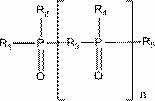

Liquid halogen-free phosphorus-nitrogen collaboration flame retardant and preparation method thereof

A technology of synergistic flame retardant and flame retardant, applied in the fields of manufacturing tools, inorganic compound addition, textile and paper making, etc. Good application value and economic benefits, easy control and industrialization, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

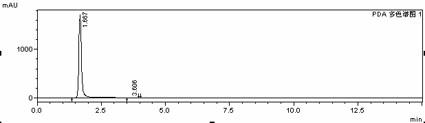

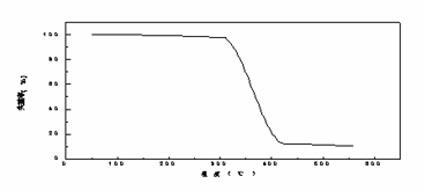

[0029] Add 49.8g of phosphorus oxychloride in a two-necked flask equipped with a reflux device and a tail gas absorption device. Heat it to 40°C in a constant temperature oil bath with stirring, add a funnel to the other mouth of the two-necked bottle, control the dropping rate to 10ml / min and add 10.1g of ethylene glycol dropwise. The temperature was 50°C, and the reaction was continued for one hour. Add 10.4 g of urea in small portions. After the addition is completed, raise the temperature to 80° C., add 19.6 g of urea in small portions, continue the reaction for one hour, and cool naturally. That is, a milky white transparent viscous liquid flame retardant product is obtained. The yield is 100%. The product has a boiling point of 220°C and a 1% decomposition temperature of 330°C.

[0030] Dissolve 10 g of the liquid halogen-free phosphorus nitrogen synergistic flame retardant obtained in Example 1 into 100 ml of water, soak common kraft wrapping paper in water for 10 m...

Embodiment 2

[0032] Add 70g of phosphoric acid, 10ml of cyclohexane (water removal agent) and 3ml of concentrated sulfuric acid catalyst into a two-necked flask equipped with a reflux device and a tail gas absorption device, and reflux at a constant temperature to remove water. Heat to 80° C. in a constant-temperature oil bath with stirring, and add 32.1 g of urea in small portions. After the addition was complete, the temperature was raised to 90°C, and the reaction was continued for one hour. Control the dropping rate at 7ml / min and add 50g of ethanol dropwise. After the dropwise addition is completed, keep the constant temperature at 90°C and continue the reaction for 0.2 hours. After distilling off the water-removing agent inside, cool naturally. That is, a colorless and transparent viscous liquid flame retardant product is obtained. The yield was 93%. The product has a boiling point of 200°C and a 1% decomposition temperature of 320°C.

[0033] 16g of the liquid halogen-free phosph...

Embodiment 3

[0035]Add 40g of phosphorus pentachloride in a two-necked flask equipped with a reflux device and a tail gas absorption device. Heat to 30°C in a constant temperature oil bath with stirring, add a funnel to the other port of the two-neck bottle, add 14.1 g of resorcinol in small portions, raise the temperature to 50°C, and continue the reaction for one hour. 6.2 g of propanol was added dropwise at a rate of 10 ml / min, and the reaction was continued at a constant temperature for 0.1 hour after the dropwise addition was completed. Then add 7.7 g of urea into the reactor in small amounts, and after the addition of the sample is completed, raise the temperature to 80° C., continue the reaction for one hour, and cool naturally. That is, a bright yellow transparent viscous liquid flame retardant product is obtained. The yield was 96%. The product has a boiling point of 200°C and a 1% decomposition temperature of 330°C.

[0036] 16g of the liquid halogen-free phosphorus nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com