Acrylic acid textile size and preparation method thereof

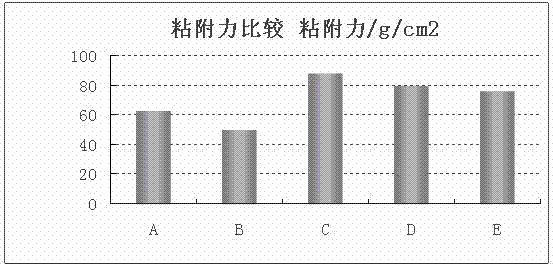

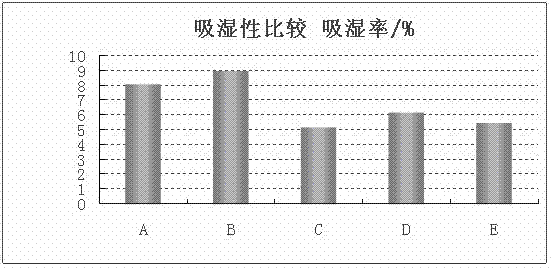

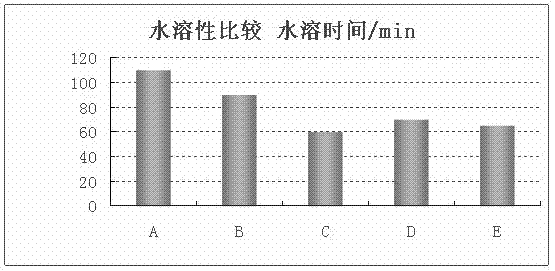

A technology of textile pulp and acrylic, which is applied in textiles, papermaking, fiber treatment, etc. It can solve the problems of not being able to use a large amount, poor water solubility and water dispersibility, and low strength of the size film, and achieve low hygroscopicity and yarn hairiness. , The effect of increasing yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Raw materials: methyl acrylate (MA), butyl acrylate (BA), acrylic acid (AA), acrylamide (AM), ammonium persulfate (APS), complex emulsifier, ammonia water and deionized water, of which

[0041] 7 parts methyl acrylate

[0042] Butyl acrylate 12 parts

[0043] Acrylic 11 parts

[0044] 3 parts acrylamide

[0045] Initiator 0.8 parts

[0046] Compound emulsifier 6 parts

[0047] Ammonia 6 parts

[0048] 55 parts of deionized water;

[0049] Described composite emulsifier is the mixture of fatty alcohol polyoxyethylene ether AEO-5 and AEO-7, and the mass ratio of the two is: 2:3

[0050]Synthesis method: Add deionized water, acrylamide, acrylic acid and compound emulsifier into a three-necked flask with a volume of 1000ml, and then add 25%-35% of the mixed monomer of methyl acrylate and butyl acrylate, and then carry out Stir and raise the temperature to 88°C-93°C, add the ammonium persulfate aqueous solution and the remaining monomer mixed with methyl acrylate and ...

Embodiment 2

[0052] The difference between the present embodiment and embodiment 1 is that the weight parts consumption of each raw material is as follows:

[0053] 5 parts methyl acrylate

[0054] Butyl acrylate 15 parts

[0055] Acrylic 8 parts

[0056] Acrylamide 5 parts

[0057] Initiator 0.5 parts

[0058] Compound emulsifier 5 parts

[0059] Ammonia 5 parts

[0060] 50 parts of deionized water.

Embodiment 3

[0062] The difference between the present embodiment and embodiment 1 is that the weight parts consumption of each raw material is as follows:

[0063] 8 parts methyl acrylate

[0064] Butyl acrylate 10 parts

[0065] Acrylic 15 parts

[0066] 2 parts acrylamide

[0067] Initiator 1 part

[0068] Compound emulsifier 10 parts

[0069] Ammonia 8 parts

[0070] 60 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com