Method for preparing nano Ag/PVP (polyvinyl pyrolidone) composite material by utilizing ultraviolet irradiation

A composite material and ultraviolet light technology, which is applied in the field of preparing nano-Ag/PVP composite materials by ultraviolet light irradiation, can solve the problems of complex reaction system, nuclear pollution, and affecting material performance, and achieve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

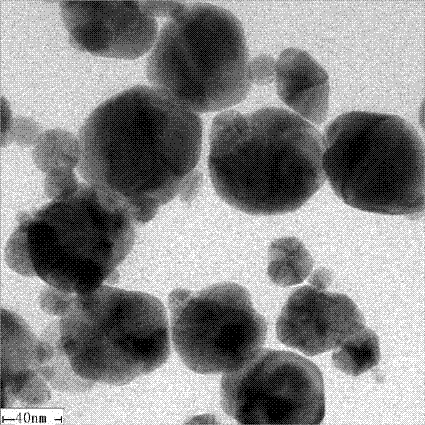

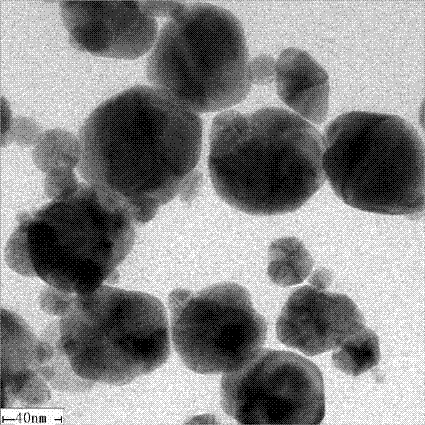

Image

Examples

Embodiment 1

[0022] Take a certain amount of NVP monomer, dissolve it in 5 times the volume of distilled water, and then add a certain amount of 8wt%AgNO 3 solution, the mixture was stirred uniformly so that Ag + The concentration of ions in the system is 0.01mol / L, and the mixture is irradiated with ultraviolet light for 25 minutes, and the NVP monomer is polymerized to form PVP by ultraviolet radiation, and the Ag is irradiated by ultraviolet radiation at the same time. + Reducted into Ag particles, and aggregated into nano-Ag and dispersed in PVP, the final sauce brown solution is nano-silver / PVP composite.

Embodiment 2

[0024] Take a certain amount of NVP monomer, dissolve it in 10 times the volume of distilled water, and then add a certain amount of 8wt% AgNO 3 solution, the mixture was stirred uniformly so that Ag + The concentration of ions in the system is 0.02mol / L, and the mixture is irradiated with ultraviolet light for 20 minutes, and the finally obtained sauce brown solution is the nano-silver / PVP composite.

Embodiment 3

[0026] Take a certain amount of NVP monomer, dissolve it in 12 times the volume of distilled water, and then add a certain amount of 8wt% AgNO 3 solution, the mixture was stirred uniformly so that Ag + The concentration of ions in the system is 0.04mol / L, and the mixture is irradiated with ultraviolet light for 30 minutes, and the finally obtained sauce brown solution is nano-silver / PVP composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com