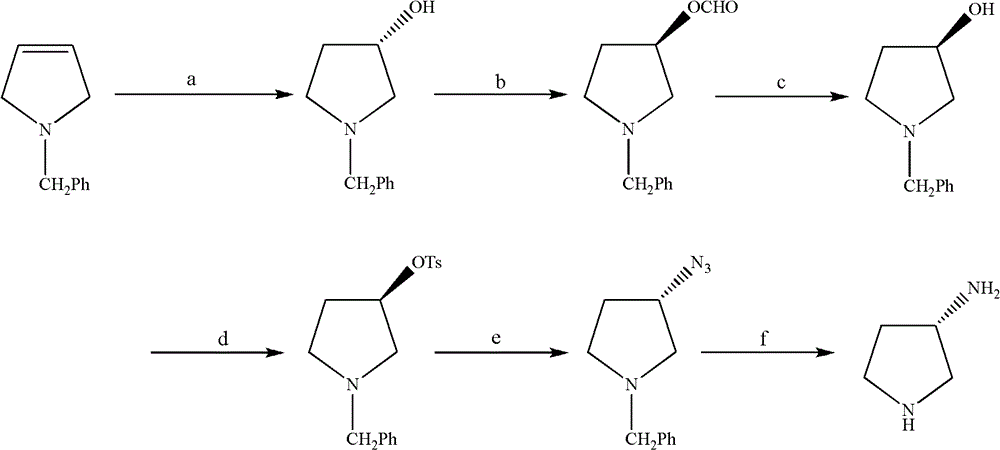

The synthetic method of (s)-3-aminopyrrolidine dihydrochloride

A technology of aminopyrrolidine dihydrochloride and hydroxypyrrolidine hydrochloride, which is applied in the field of preparation of chiral drugs, can solve the problems of difficult recovery of solvent THF and cumbersome operation, and achieve low cost, readily available raw materials, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of (R)-3-hydroxypyrrolidine hydrochloride (II)

[0042] Trans-4-hydroxy-L-proline (100.0g, 0.75mol), cyclohexanol (500.0ml) and 2-cyclohexen-1-one (10.0ml, 0.11mol) were mixed well, heated to 154°C, heat preservation reaction for 5h, after cooling to room temperature, add toluene (500ml), cool to about 0°C in an ice-water bath, introduce dry hydrogen chloride gas to pH 2-3, stir at about 5°C for 1h, filter to obtain a solid , recrystallized with isopropanol (300ml) to obtain light pink crystalline solid II (75.0g, 80.0%), mp: 104~107℃

[0043] Yield: 80.0%

[0044] Preparation of (R)-1-tert-butoxycarbonyl-3-methanesulfonyloxypyrrolidine (III)

[0045] The light pink crystalline solid II (12.4g, 0.10mol) was placed in a solution of dichloromethane (200ml), cooled to 0°C, triethylamine (18.0ml, 0.13mol) was added, and after stirring uniformly, ( Boc) 2 A solution of O (22.0g, 0.10mol) in dichloromethane (100ml) was reacted at 0°C for 3h, then triethylamine...

Embodiment 2

[0058] Preparation of (R)-3-hydroxypyrrolidine hydrochloride (II)

[0059] Trans-4-hydroxy-L-proline (10.0g, 0.75mol), cyclohexanol (50.0ml) and 2-cyclohexen-1-one (1.0ml, 0.11mol) were mixed well and heated to 150 ℃, heat preservation reaction for 3h, after cooling to room temperature, add toluene (50ml), cool to about 0 ℃ in ice-water bath, pass dry hydrogen chloride gas to pH 2~3, stir at about 5 ℃ for 1h, filter to obtain solid , recrystallized with isopropanol (30ml) to give light pink crystalline solid II (7.7g, 82.1%), mp: 104~107℃

[0060] Yield: 82.1%

[0061] Preparation of (R)-1-tert-butoxycarbonyl-3-methanesulfonyloxypyrrolidine (III)

[0062] The light pink crystalline solid II (62.1g, 0.50mol) was placed in a solution of dichloromethane (800ml), cooled to 0°C, triethylamine (90.0ml, 0.65mol) was added, and after stirring uniformly, ( Boc) 2 A solution of O (110.0g, 0.50mol) in dichloromethane (400ml) was reacted at 0°C for 3h, then triethylamine (80.0ml, 0.55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com