Method for preparing 11-bromo-undecanoic acid by direct freezing crystallization and device therefor

A technology of freezing crystallization and undecanoic acid, which is applied in the field of preparation of 11-bromoundecanoic acid, can solve the problems of large post-processing workload, large water consumption, and increased costs, and achieves low production costs, good economic benefits, response constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

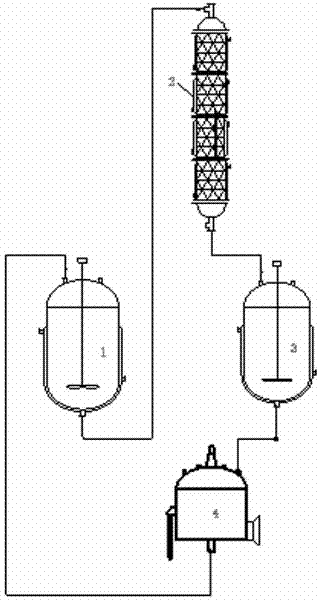

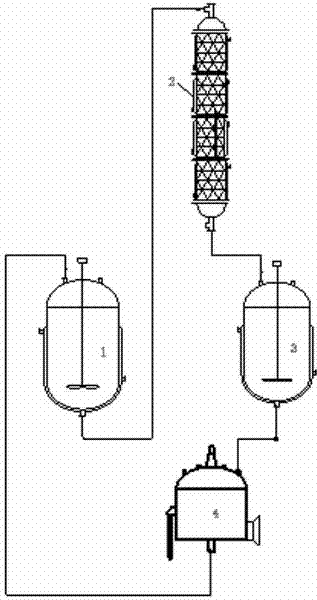

[0018] Such as figure 1 The preparation device of the direct freeze crystallization of shown 11-bromoundecanoic acid comprises batching kettle 1, addition tower 2, crystallization kettle 3, filter press 4, and wherein the outlet at the bottom of batching kettle 1 and addition tower 2 The feed port at the top is connected, the feed port at the bottom of the addition tower 2 is connected with the feed port at the top of the crystallization kettle 3, the feed port at the bottom of the crystallization kettle 3 is connected with the feed port of the filter press 4, and the filter press The discharge port at the bottom of 4 is connected with the feed port at the top of batching kettle 1.

[0019] When working, the following steps are involved:

[0020] (1) Under the condition of keeping the temperature at -5°C in the batching kettle 1, mix undecylenic acid and toluene to obtain undecylenic acid toluene solution, wherein the mass ratio of undecylenic acid and toluene is 1:3.5;

[0...

Embodiment 2

[0026] Such as figure 1 The preparation device of the direct freeze crystallization of shown 11-bromoundecanoic acid comprises batching kettle 1, addition tower 2, crystallization kettle 3, filter press 4, and wherein the outlet at the bottom of batching kettle 1 and addition tower 2 The feed port at the top is connected, the feed port at the bottom of the addition tower 2 is connected with the feed port at the top of the crystallization kettle 3, the feed port at the bottom of the crystallization kettle 3 is connected with the feed port of the filter press 4, and the filter press The discharge port at the bottom of 4 is connected with the feed port at the top of batching kettle 1.

[0027] When working, the following steps are involved:

[0028] (1) Mix undecylenic acid and toluene under the condition of keeping the temperature at -3°C in the batching kettle 1 to obtain undecylenic acid toluene solution, wherein the mass ratio of undecylenic acid and toluene is 1:4;

[0029...

Embodiment 3

[0034] Such as figure 1 The preparation device of the direct freeze crystallization of shown 11-bromoundecanoic acid comprises batching kettle 1, addition tower 2, crystallization kettle 3, filter press 4, and wherein the outlet at the bottom of batching kettle 1 and addition tower 2 The feed port at the top is connected, the feed port at the bottom of the addition tower 2 is connected with the feed port at the top of the crystallization kettle 3, the feed port at the bottom of the crystallization kettle 3 is connected with the feed port of the filter press 4, and the filter press The discharge port at the bottom of 4 is connected with the feed port at the top of batching kettle 1.

[0035] When working, the following steps are involved:

[0036] (1) Under the condition of keeping the temperature at 0°C in the batching kettle 1, mix undecylenic acid and toluene to obtain undecylenic acid toluene solution, wherein the mass ratio of undecylenic acid and toluene is 1:3;

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com