Multiphase ceramics material with low density and high strength and preparation method thereof

A technology of multiphase ceramics and ceramic materials, applied in the field of ceramic materials, can solve the problems of many pores, poor mechanical properties, unsuitability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

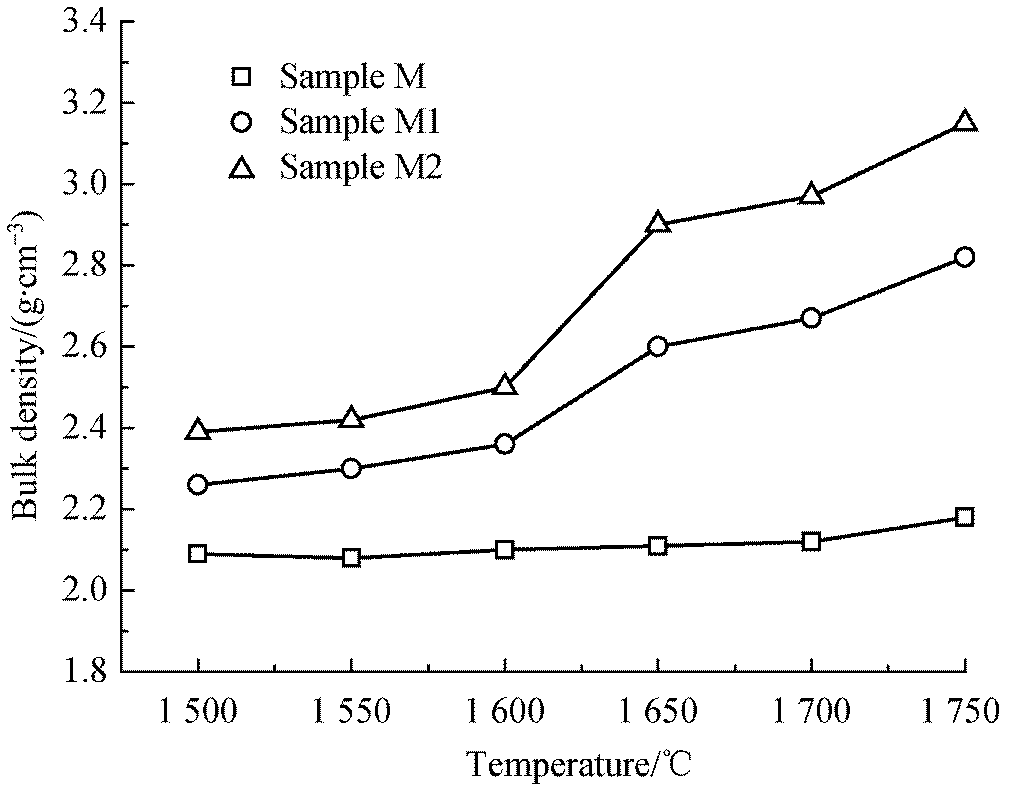

[0059] Embodiment 1~7 sample composition

[0060]

[0061] Among them, micron SiC 1 (1μm≤D 50 ≤100μm, purity >98%), submicron SiC 2 (0.1μm≤D 50 98%), Si powder (0.1μm≤D 50 99%), industrial grade Al 2 o 3 (0.1μm≤D 50 2 (analytical pure), high-quality Suzhou soil (1μm≤D 50 ≤100μm), additive Y 2 o 3 , ZrO 2 , La 2 o 3 , MgO (0.5μm≤D 50 ≤10 μm, purity >99%).

[0062] Embodiment 1~7 preparation method: take ethanol as ball milling medium, use Si in planetary mill 3 N 4 Ball milling 24h (raw materials and additives, Si 3 N 4 The mass ratio of balls to ethanol is 1:1.5:1), and the ball-milled slurry is dried, granulated, sieved, dry-pressed (45-55MPa), degummed, and sintered in a high-temperature vacuum atmosphere Sintering in flowing high-purity nitrogen gas (purity > 99.99%) produces a low-density, high-strength composite ceramic material, that is, SiC / β-sialon composite ceramic.

Embodiment 1~2

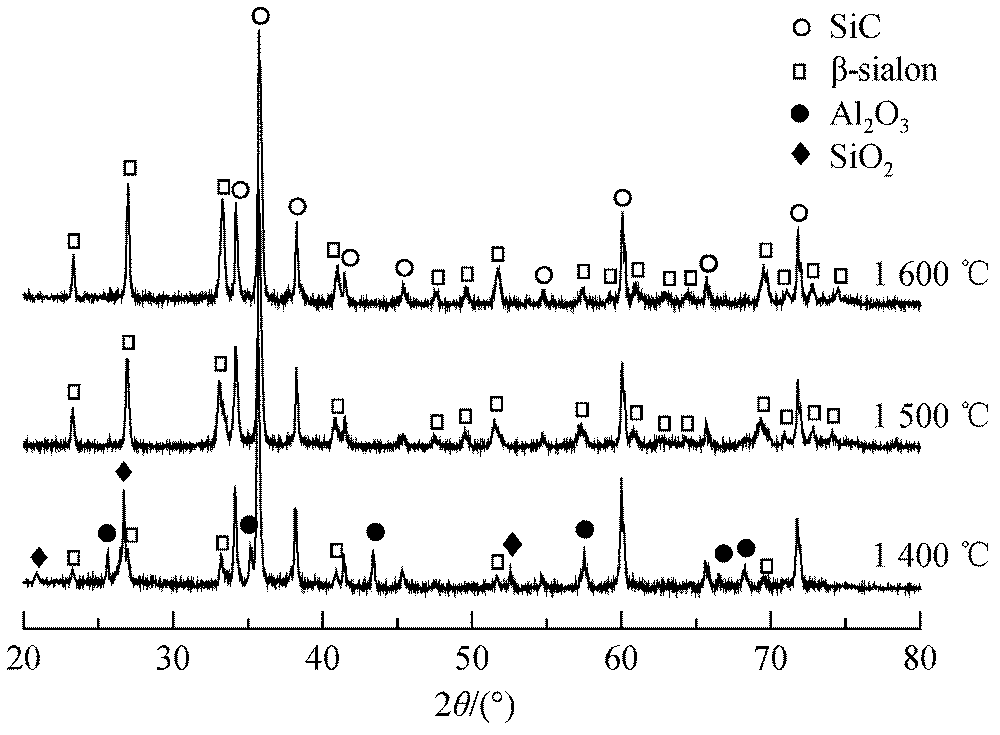

[0064] The specific sintering method is to keep the temperature at 1500°C for 2 hours under flowing high-purity nitrogen gas (purity>99.99%) (nitrogen flow rate: 1-3L / min), and then rapidly raise the temperature to 1650°C at a rate of 10°C / min Keep warm for 1h. In this method, the temperature used for debinding is 300° C., and the temperature is kept for 3 hours.

[0065] Examples 1-2 The apparent porosity of the ceramic material is 5-25%, 75%3 .

Embodiment 3~4

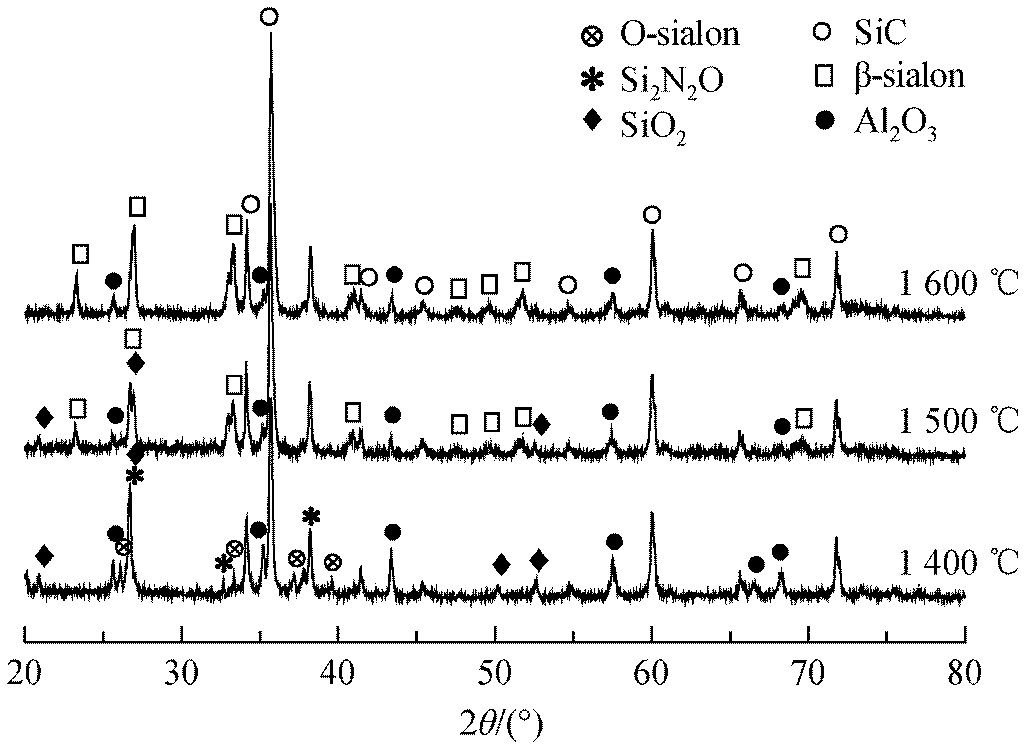

[0067] The specific sintering method is to keep the temperature at 1400°C for 3 hours under flowing high-purity nitrogen gas (purity>99.99%) (nitrogen flow rate: 1-3L / min), and then rapidly heat up to 1600°C at a rate of 15°C / min Keep warm for 3h. In this method, the temperature used for debinding is 400° C., and the temperature is kept for 2 hours.

[0068] Examples 3-4 The apparent porosity of the ceramic material is 5-20%, 75%3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com