Microcrystal glass ceramic bond for diamond composite materials

A ceramic bond and composite material technology, applied in the field of diamond composite grinding tools, can solve the problems of reducing the bonding strength of diamond abrasive grains, reducing the service life of composite materials, increasing grinding costs, etc., to meet the requirements of high-speed grinding, analysis The effect of low crystal temperature and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention adopts the conventional preparation method, Li with β-spodumene as main crystal phase 2 O-Al 2 o 3 -4SiO 2 Glass-ceramic as the basic binder, the introduction of B 2 o 3 / Na 3 AlF 6 / Na 2 O multi-component composite flux, after mixing uniformly by ball milling, it is melted into a glass melt at 1200-1400°C, water quenched, dried, and crushed into glass powder to obtain a binder, which is also the precursor of a glass-ceramic binder body. The powder sintering method is used to obtain the glass-ceramic bonding agent, and the sintering crystallization temperature is 680-780°C.

[0018] See Table 1 for specific examples of the basic glass powder and composite fluxing agent of the present invention.

[0019] Table 1

[0020]

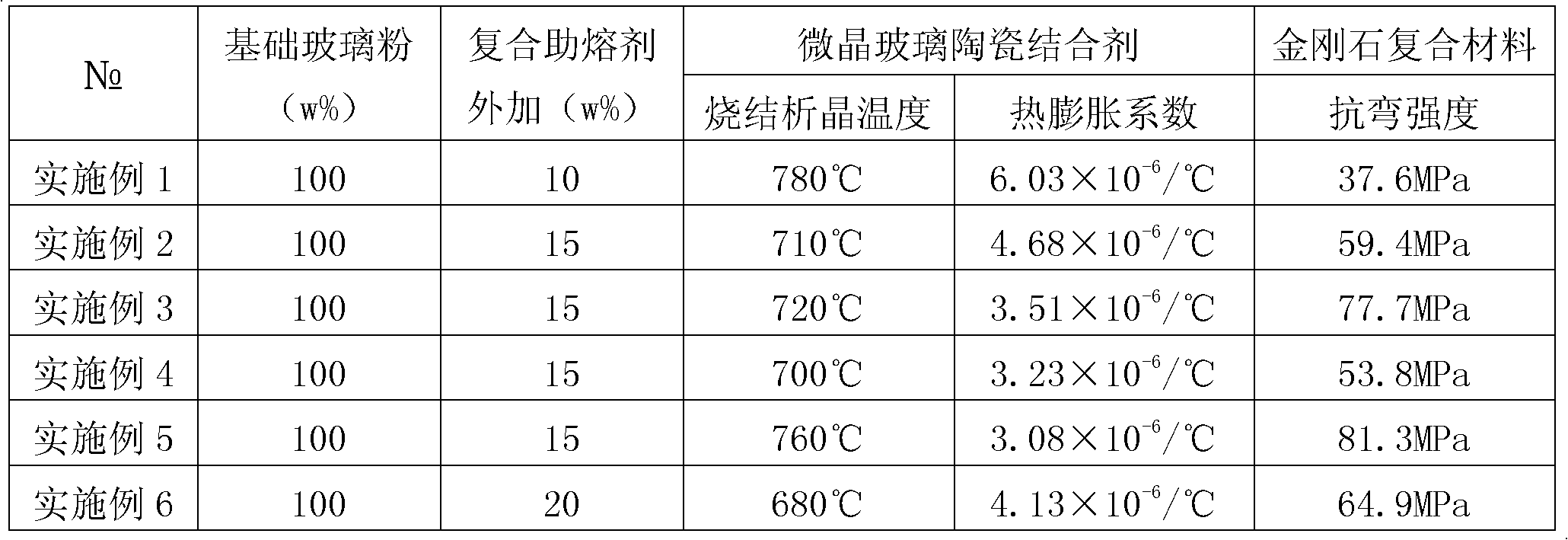

[0021] See Table 2 for specific examples of the present invention's glass-ceramic binder and its performance test results.

[0022] Table 2

[0023]

[0024] The specific crystallization temperature of Examples 1...

Embodiment 5

[0025] Taking Example 5 as an example, the specific preparation process of the glass-ceramic bond for diamond composite material of the present invention is:

[0026] Weigh the components of the basic glass powder and the flux according to the formula, mix them uniformly through ball milling, melt them in a high-temperature furnace at 1400°C, and pass through a 200-mesh sieve through water quenching, drying, and sieve to obtain Precursor of glass-ceramics bond that can be crystallized by heat treatment. When the precursor of the glass-ceramic bond is used as a bond for diamond composite materials, after nucleation treatment at 650°C and crystallization treatment at 760°C, the glass powder can be crystallized and transformed into glass-ceramic, thus becoming a glass-ceramic bond. agent. Its coefficient of thermal expansion is 3.08×10 -6 / ℃, and the thermal expansion coefficient of diamond is 3.1×10 -6 / °C match. The bending strength of the diamond composite material prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com