Ozone generating apparatus

An ozone generating device and ozonation technology are applied in ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., which can solve the problems of difficulty in maintaining discharge gap and inability to perform uniform discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

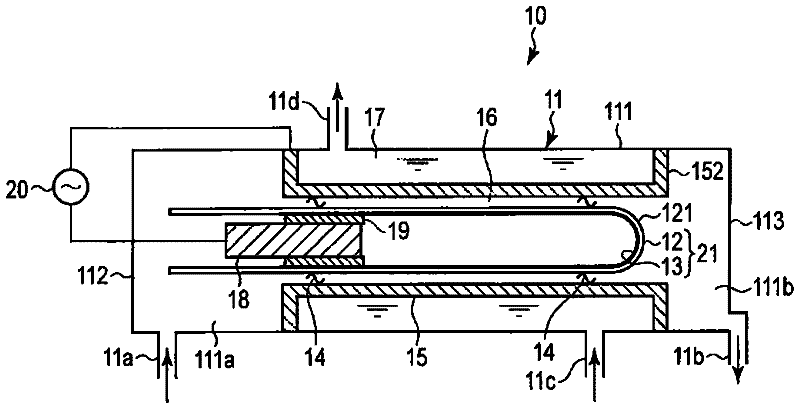

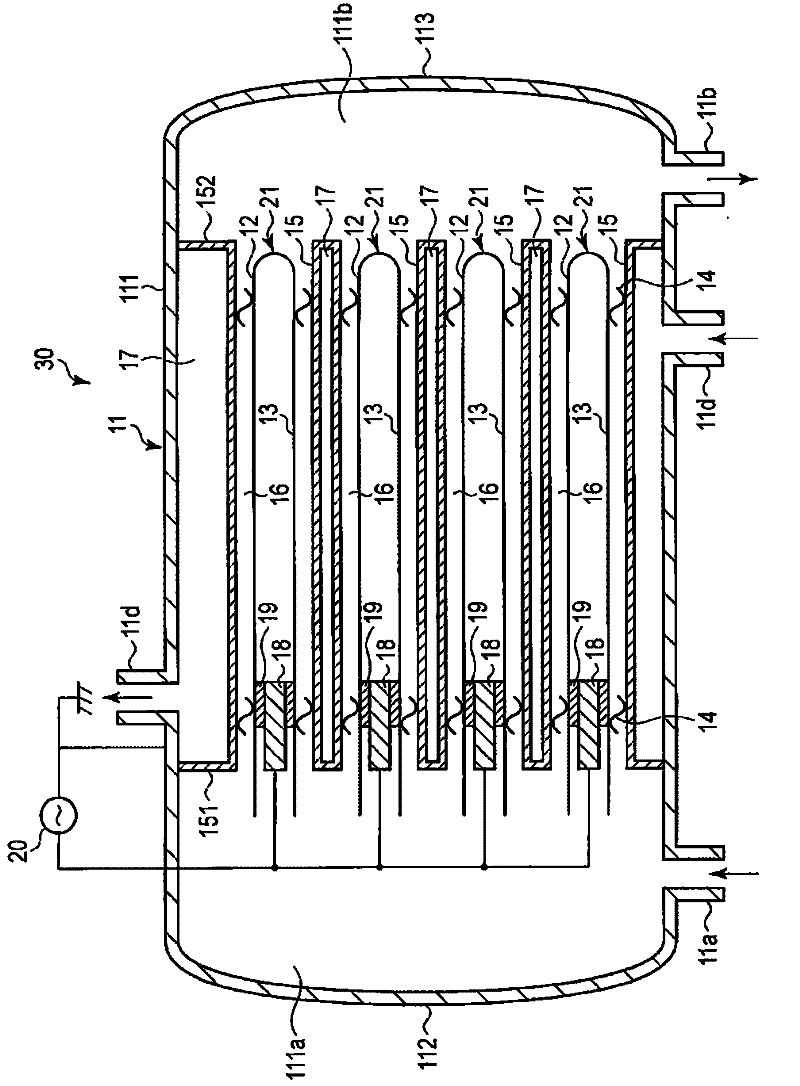

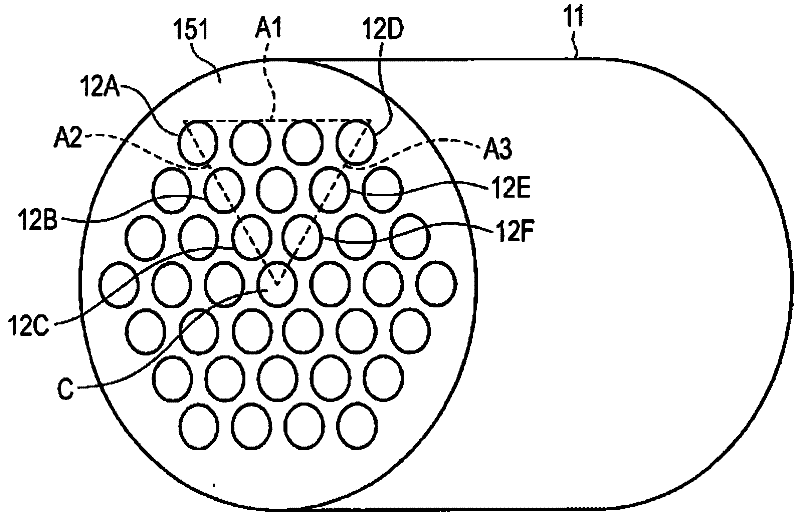

[0017] An ozone generator according to one embodiment generates an ozonated gas from a source gas containing oxygen. The ozone generating device is provided with: a cylindrical airtight container with an inlet of the raw material gas and an outlet of the ozonated gas; a discharge tube including a dielectric tube disposed in the container and a discharge tube disposed inside the dielectric tube. a first electrode; a second electrode, spaced apart from the discharge tube and disposed in the airtight container surrounding the first electrode, so as to form a discharge gap between the second electrode and the discharge tube; a discharge voltage source configured to apply a discharge voltage between the first electrode and the second electrode; and a cooling water jacket surrounding the second electrode. The dielectric tube has an outer diameter of 12 mm or more and 19 mm or less.

[0018] Here, if the outer diameter of the dielectric tube exceeds the range of 12 mm or more and 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com