High elasticity corrugated board

A technology of corrugated cardboard and corrugated paper, which is applied in the field of corrugated cardboard, can solve the problems of wasting resources, corrugated cardboard has limited strength, impact resistance, and reduced packaging space, and achieves the effects of saving resources, not easy to puncture, and increasing peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

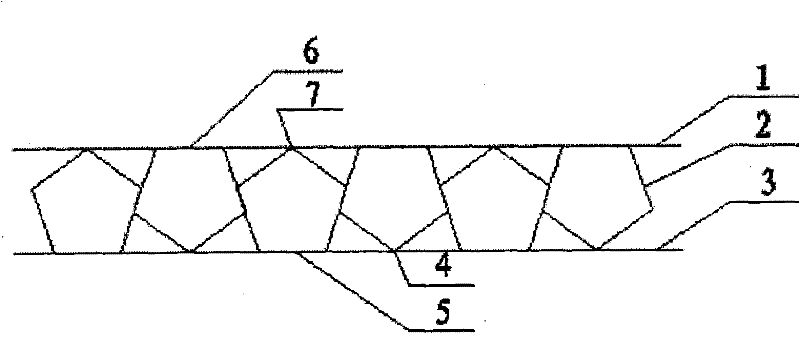

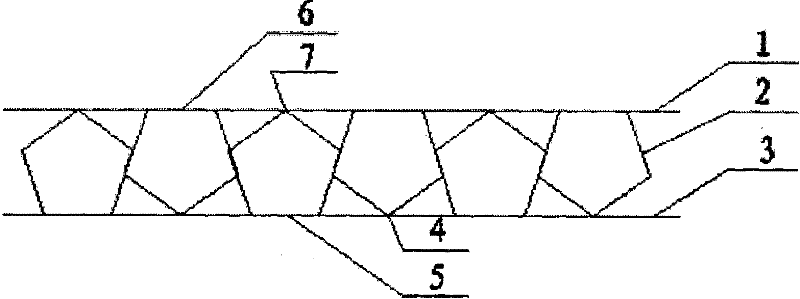

[0013] The outer surface paper 1 and the bottom surface paper 3 are sandboard or kraft paper, and the regular pentagonal corrugated paper core 2 is corrugated base paper.

[0014] Regular pentagonal corrugated paper core 2 is composed of individual hollow regular pentagonal paper tubes bonded together, and the sides of adjacent regular pentagons are bonded to each other, and it is an upright regular pentagon and an inverted regular pentagon. The polygons are staggered and bonded.

[0015] The lower surface of the outer layer paper 1 is bonded to the upper surface of the regular pentagonal corrugated paper core 2, and the regular pentagonal corrugated paper core is bonded successively to the crest 7, the upper side 6, and the crest 7, proceeding in turn...; the bottom face paper 1 The upper surface is bonded to the lower surface of the regular pentagonal corrugated paper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com