Casting and forming method for double-layer-material engine cylinder liner

An engine cylinder and casting forming technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of small reinforced particle density, decreased toughness, and many processes, so as to meet the requirements of heat resistance and wear resistance, improve processing performance, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

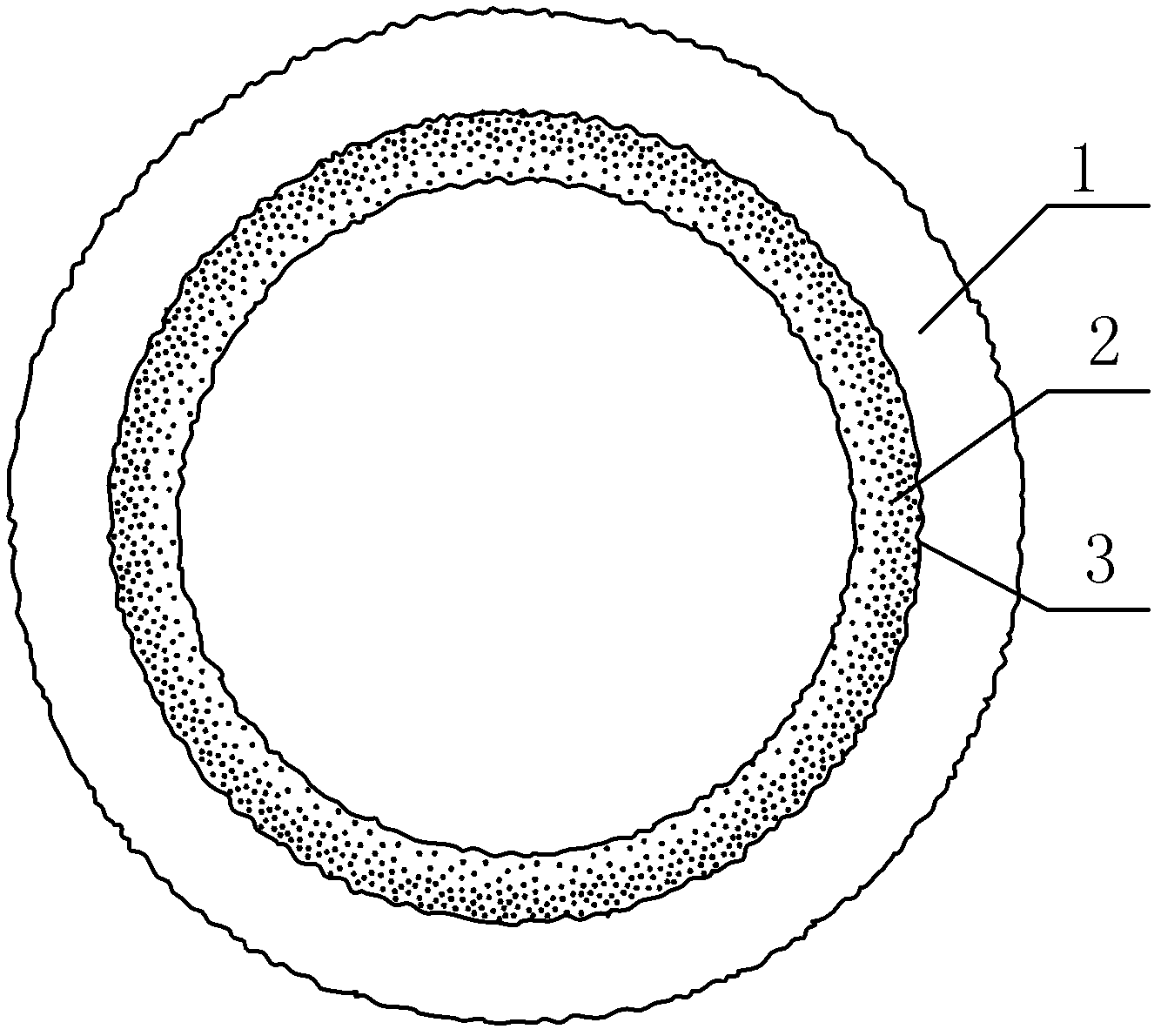

[0032] As shown in Figure 1, the cross-sectional structure diagram of the double-layer material engine cylinder liner prepared by the present invention, the outer layer 1 is a light alloy material; the inner layer 2 is a particle reinforced composite material, and the number of particles in the inner layer 2 is enhanced from the inside to the outside Gradually increase, that is, the inner surface of the inner layer 2 is a grain-poor layer; the interface 3 is a two-layer material interface mainly composed of metallurgical bonding and supplemented by geometric structure bonding.

[0033] A double-layer material engine cylinder liner casting method is to use a combination of double ladle casting and traditional centrifugal casting to realize a double-layer engine cylinder with light alloy material on the outer radial layer of the cylinder liner and particle reinforced composite material on the inner layer The casting forming of the sleeve includes the following steps and process cond...

Embodiment 2

[0042] The invention uses the method of combining double ladle pouring and traditional centrifugal casting to realize the casting of a double-layer engine cylinder liner in which the radial outer layer of the cylinder liner is a light alloy material and the inner layer is a particle-reinforced composite material, including the following steps and The process conditions:

[0043] Step 1: Preparation of outer layer light alloy and inner layer composite melt

[0044] (1) Melt the light alloy of the outer layer material and inner layer base material of the double-layer material cylinder liner respectively in two melting furnaces. In the smelting process, ADC12 aluminum alloy (the same as the die-cast aluminum alloy engine block material) is selected as the outer layer material, and the melting temperature is 720°C; the inner matrix material is 6061 aluminum alloy, and the melting temperature is 750°C.

[0045] (2) SiC particles are added to the melt with 6061 aluminum alloy as the inner...

Embodiment 3

[0051] The invention utilizes the method of combining double ladle pouring and traditional centrifugal casting to realize the casting and forming of a double-layer engine cylinder liner in which the radial outer layer of the cylinder liner is made of light alloy material and the inner layer is made of particle-reinforced composite material, including the following steps and The process conditions:

[0052] Step 1: Preparation of outer layer light alloy and inner layer composite melt

[0053] (1) Melt the light alloy of the outer layer material and inner layer base material of the double-layer material cylinder liner respectively in two melting furnaces. In the smelting process, the outer layer material is A356 aluminum alloy (the same as the gravity cast aluminum alloy engine block material), and the melting temperature is 720°C; the inner matrix material is 2024 aluminum alloy, and the melting temperature is 750°C.

[0054] (2) The inner matrix material is 2024 aluminum alloy melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com