Method for determining trace nitrogen-containing disinfection by-product dimethyl nitrosamine in water

A technology of dimethylnitrosamine and disinfection by-products, which is applied in the field of determination of trace nitrogen-containing disinfection by-products of dimethylnitrosamine in water, can solve the problems of complex operation steps, reduced detection cycle, long detection cycle, etc. Achieve the effects of improving extraction efficiency, reducing matrix interference, and shortening the detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

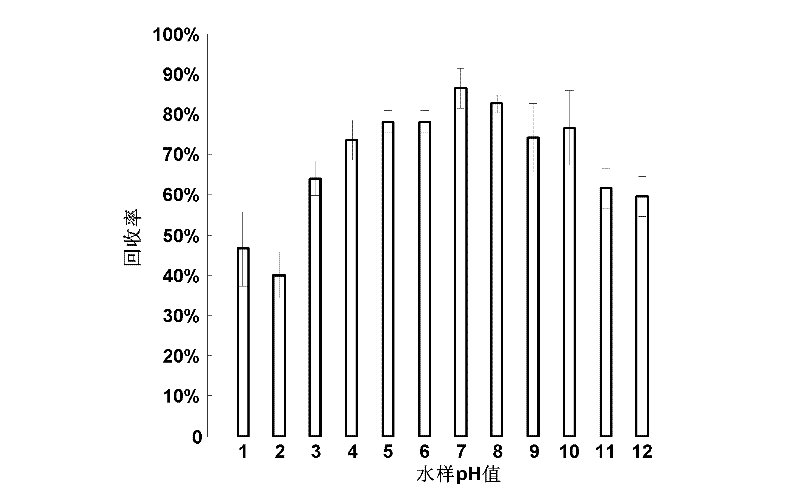

[0033] The water sample was Mill-Q water (ultrapure water). In 12 groups of 500mL Mill-Q water (ultrapure water), NDMA standard was added so that the NDMA concentration was 1 μg / L. Since the water sample has no suspended solids and particulate impurities, it does not need to be filtered.

[0034] Acidification pretreatment method: use sodium hydroxide or sulfuric acid to adjust the pH value of 12 groups of water samples to be tested to 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and The water samples were placed in brown bottles and stored in a dark place.

[0035] Acidification, drying and filling of solid phase extraction materials; wood powder activated carbon used for solid phase extraction, with an average particle diameter of ≤40μm, is acidified with sulfuric acid water with a pH of 2.3, and the wood powder activated carbon is dried in an oven at 105°C after acidification dry; use a balance to take 1g of dried wood powder activated carbon and fill it into a 6mL solid-phase e...

Embodiment 2

[0043] The water sample was Mill-Q water (ultrapure water). NDMA standard was added to 5 groups of 500mL Mill-Q water (ultrapure water), so that the NDMA concentration was 1 μg / L, and the pH value of the water sample was 7, so the water sample did not need to be filtered and adjusted for pH.

[0044] Acidification pretreatment method: take 500mL water sample, put the water sample in a brown bottle and store it in a dark place.

[0045] Acidification, drying and filling of solid phase extraction materials; wood powder activated carbon used for solid phase extraction, with an average particle diameter of ≤40μm, is acidified with sulfuric acid water with a pH of 2.3, and the wood powder activated carbon is dried in an oven at 105°C after acidification Dry. Weigh 1g of dried wood powder activated carbon with a balance and fill it into a 6mL solid-phase extraction (SPE) column of high molecular weight polyethylene. The sieve plate is made of ultra-high molecular weight polyethylen...

Embodiment 3

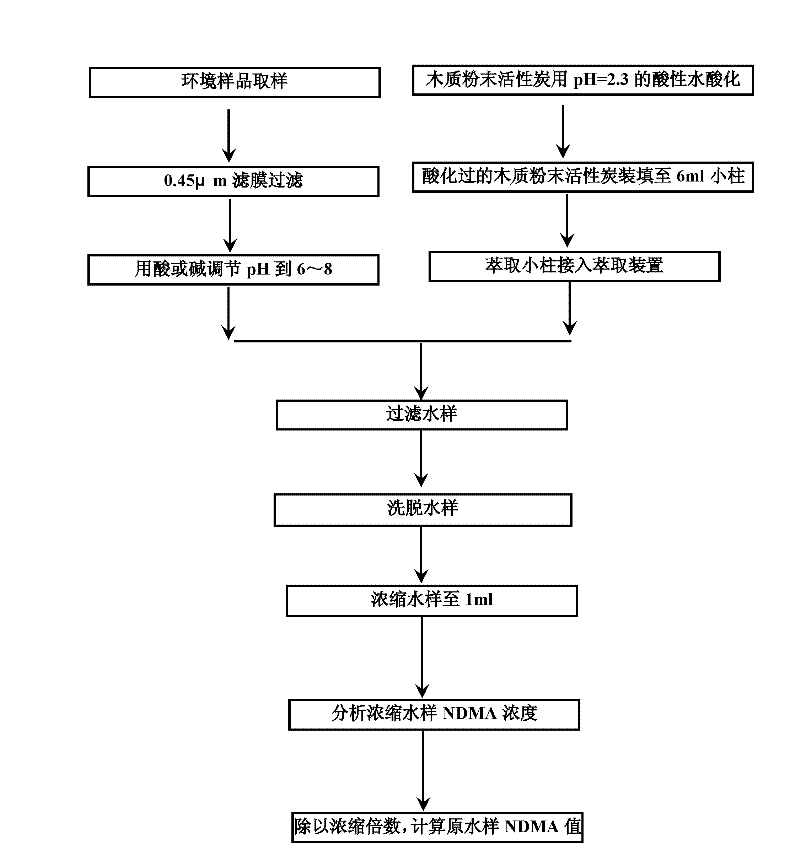

[0055] figure 1 It is the operation flowchart of the embodiment of the present invention. The water sample is surface water. Preparation process before extraction: first filter each water sample in the water purification process through a cellulose acetate membrane with a pore size less than or equal to 0.45 μm to filter out suspended solids and particulate impurities, and the water samples in the water purification process are weakly acidic. Acidification pretreatment method: Take 500mL of the filtered water sample, place it in a brown bottle and take dark measures, use sodium hydroxide to adjust the pH value of the water sample to be tested to 7, and store it in the dark.

[0056] Acidification, drying and filling of solid phase extraction materials; wood powder activated carbon used for solid phase extraction, with an average particle diameter of ≤40μm, is acidified with sulfuric acid water with a pH of 2.3, and the wood powder activated carbon is dried in an oven at 105°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com