Method for detecting appearance of capacitance product and detector implementing method

Appearance inspection and product technology, used in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of lack of inspection standards, human eye damage, easy misjudgment and missed judgment, etc., to improve product qualification rate, automation The effect of high degree and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

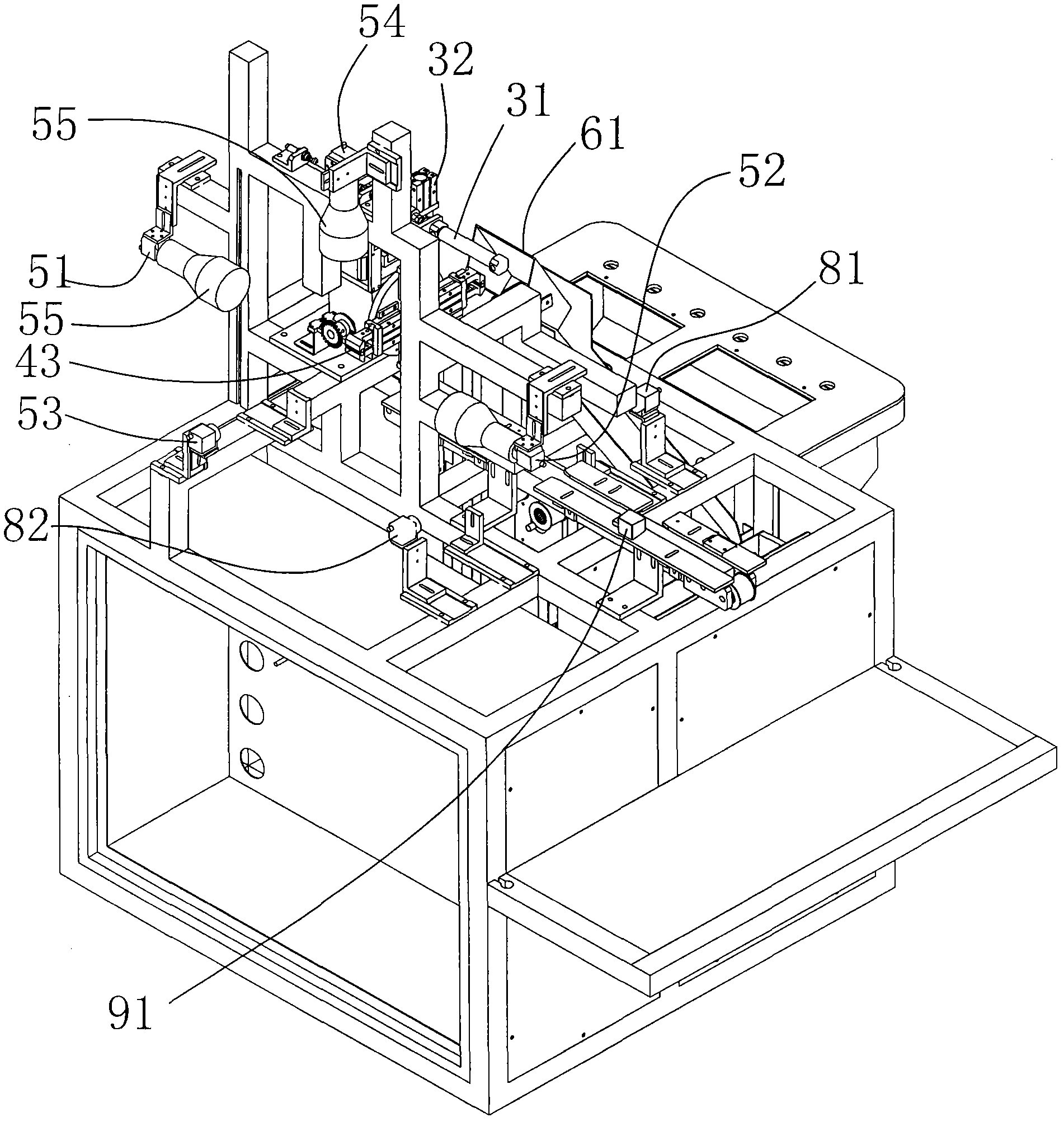

[0040] Example: see figure 1 , figure 2 and image 3 , a method for detecting the appearance of a capacitor product provided by an embodiment of the present invention, which includes the following steps:

[0041] (1) Preparation frame 1, feeding device 2, retrieving device 3, turntable mechanism hand 4, first detection device 5, first unqualified area 6, belt conveying device 7, second detection device 8, push-out device 9 , the second unqualified area 10, the final qualified area 11 and the industrial computer, which are respectively connected with the conveying device 2, the reclaiming device 3, the turntable mechanism hand 4, the first detection device 5, the belt conveying device 7, the first The second detection device 8 is connected with the push-out device 9, and controls its working state;

[0042] (2) Arrange the feeding device 2, the turntable mechanism hand 4, the belt conveying device 7, and the final qualified area "on the frame 1 in sequence;

[0043] (3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com