LED work lamp for engineering trucks

A technology for LED work lights and vehicles, applied in the field of lighting, can solve the problems of unfavorable energy saving, environmental protection, easy damage, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

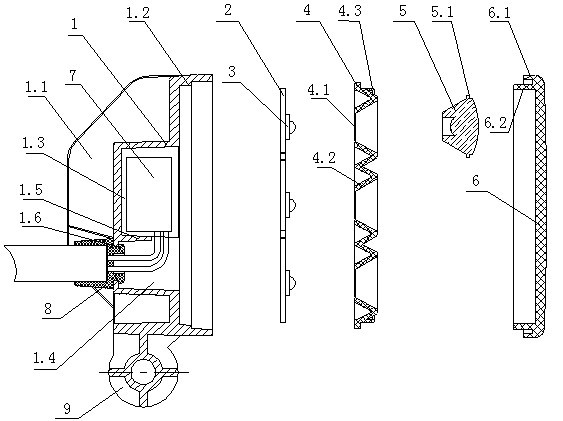

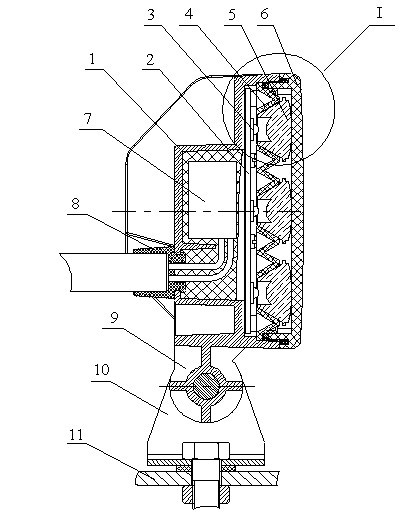

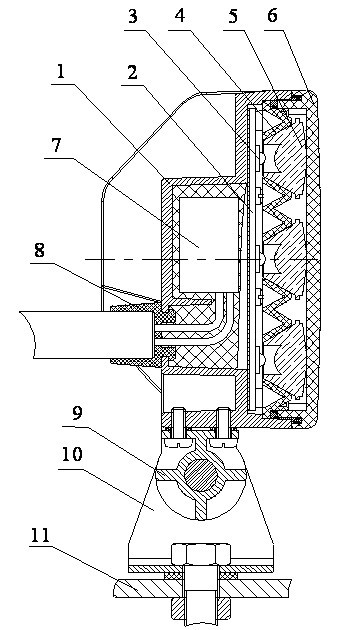

[0038] see Figure 1~16, the present invention relates to an LED work light for engineering vehicles, the work light includes a lamp holder 1, a heat sink 1.1 is provided on the back of the lamp holder 1, and a stepped surface 1.2 is provided on the inner wall of the front of the lamp holder 1 The bottom of the front of the lamp holder 1 is recessed downward to form a recessed area for placing the driving power supply 7. Specifically, the bottom of the front of the lamp holder 1 is recessed downward to form a power supply installation groove 1.3 and a connection groove 1.4. The power supply installation groove 1.3 A drive power supply 7 is installed inside, a connection hole 1.6 is provided at the bottom of the connection groove 1.4, and a waterproof joint 8 is installed at the connection hole 1.6, and a partition can be installed between the power supply installation groove 1.3 and the connection groove 1.4 according to requirements 1.5 to partition, when the partition 1.5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com