Megawatt-grade wind generating set blade capable of carrying out photovoltaic power generation and manufacturing method

A wind turbine, photovoltaic power generation technology, applied in wind turbine components, photovoltaic power generation, wind turbines, etc., can solve problems such as application difficulties, no mention of wind power blades and solar cells, etc., to avoid pollution and improve land utilization. , the production of simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

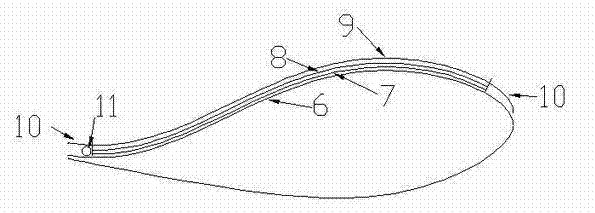

[0033] Embodiments of the present invention are described with reference to the accompanying drawings.

[0034] 1) The blades of the wind power generating set are formed by half-piece infusion molding, mold clamping and bonding, and the adhesive is cured to form a rough blank of the blade;

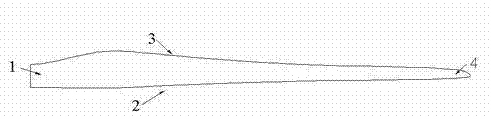

[0035] 2) The flash of the leading edge 2, trailing edge 3 and root 1 of the blade rough blank is cut off and polished smooth;

[0036] 3), the front edge 2 and trailing edge 3 of the blade shell outer surface mold clamping area needs to be strengthened for strengthening treatment;

[0037] 4) After the front edge 2 and trailing edge 3 of the blade are reinforced, they are repaired to achieve a good aerodynamic shape, and the surface of the blade shell is polished to form a uniform rough surface;

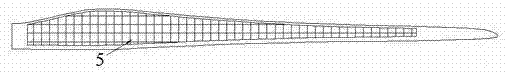

[0038] 5) On the surface of the blade (one side or both sides), mark the area 5 where the solar cell film needs to be installed. In particular, it is recommended not to install solar cells wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com