Hot working method for improving structure property of Ti5553 titanium alloy

A ti5553, microstructure and performance technology, applied in the field of material processing, can solve the problems of reduced material strength, affecting component reliability, and undeveloped processing technology β-type titanium alloy microstructure, etc., to achieve dense texture, uniform microstructure, and comprehensive performance indicators good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail through specific embodiments below.

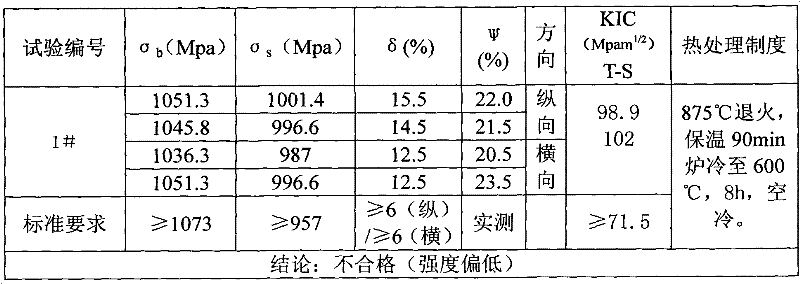

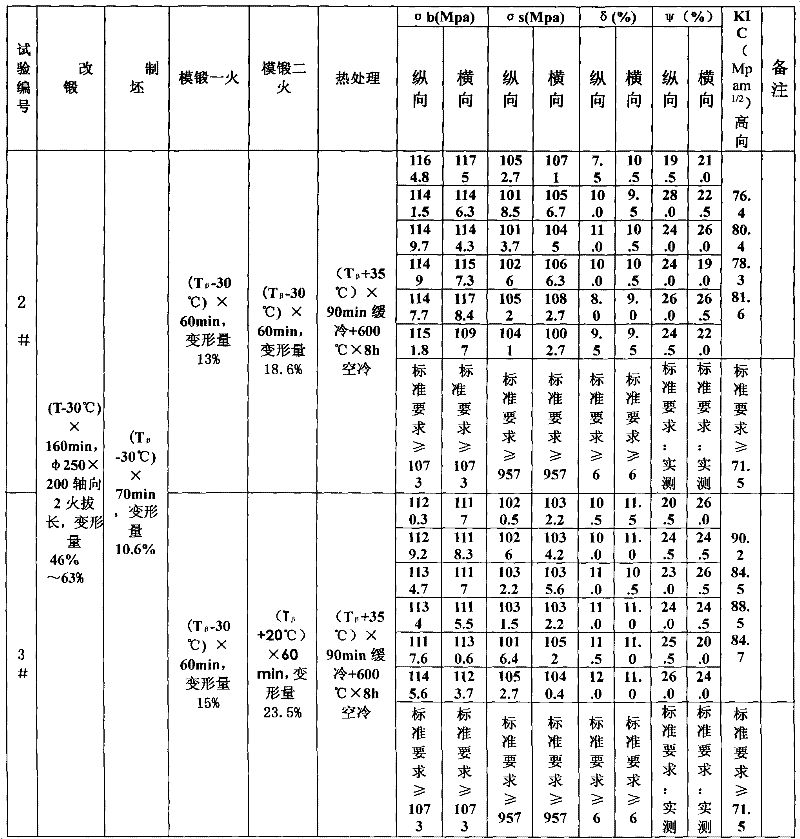

[0015] A thermal processing method for improving the microstructure and properties of Ti5553 titanium alloy, firstly, the titanium alloy blank is subjected to (α 等轴 +β 转 ) two-phase area reforging, then β forging (a forging method that is heated above the phase transition point) on the billet, and finally β heat treatment, so that it initially forms a fine and dense basket texture after reforging, During the final β heat treatment, the grain growth is limited by the intricately intertwined basket texture and a large number of dislocations during the large deformation process, and only the fine flaky α 转 The phases are rearranged and combined, nucleation and growth are driven by a large amount of dislocation energy to form a new fine texture, and the grain boundaries are composed of fine and intermittent α 转 Phase formation greatly improves the comprehensive performance inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com