Method for improving microalgae cultivation condition by using metabonomics so as to improve oil-producing capacity

A technology of microalgae culture and metabolomics, which can be used in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve problems such as unclear metabolic mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A method utilizing metabolomics to improve microalgae culture conditions to increase oil production capacity of microalgae, comprising the steps of:

[0082] (1) Determination of intracellular metabolites in Chlorella sorokiniana:

[0083] ① Chlorella sorokiniana cell collection and quenching:

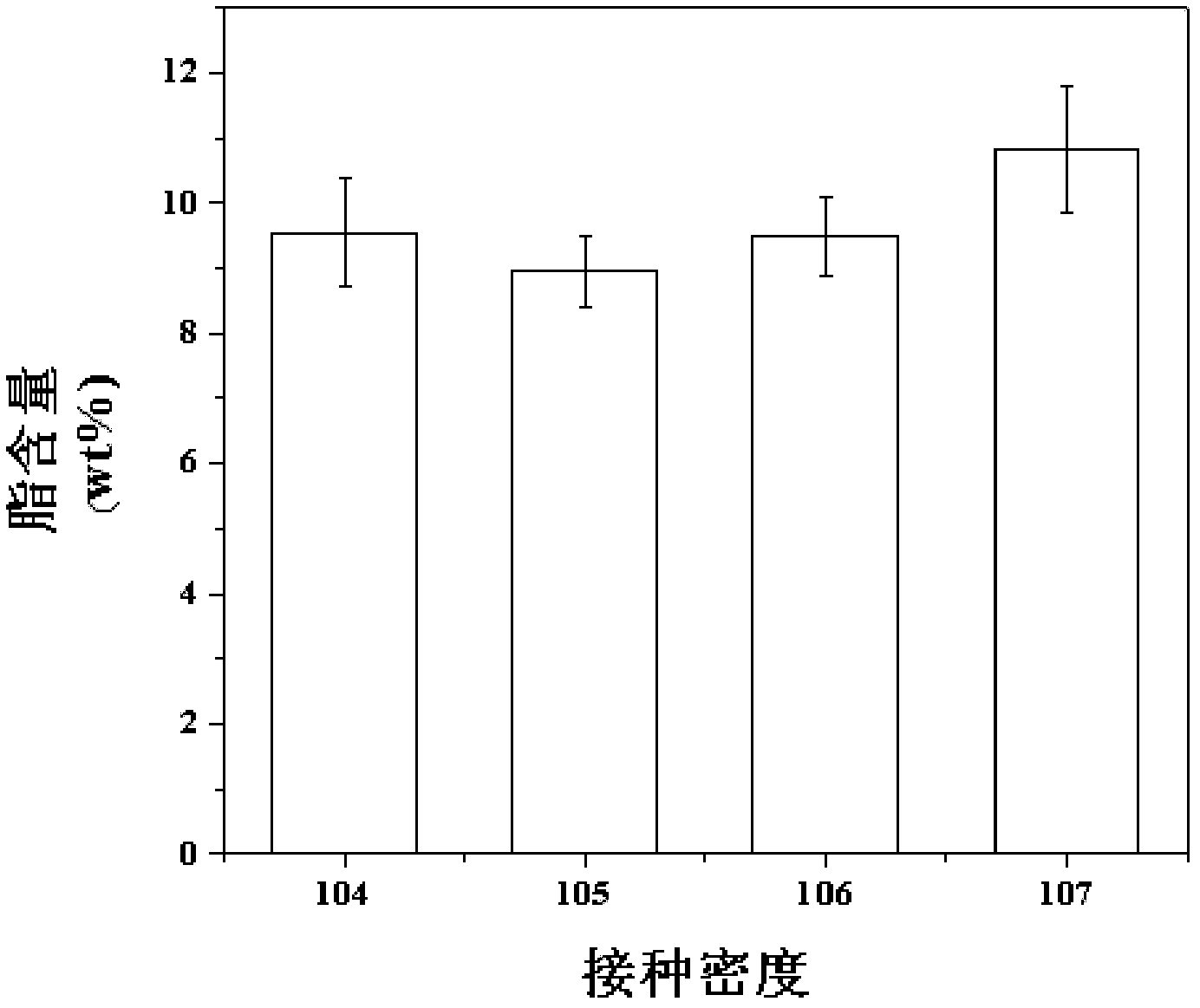

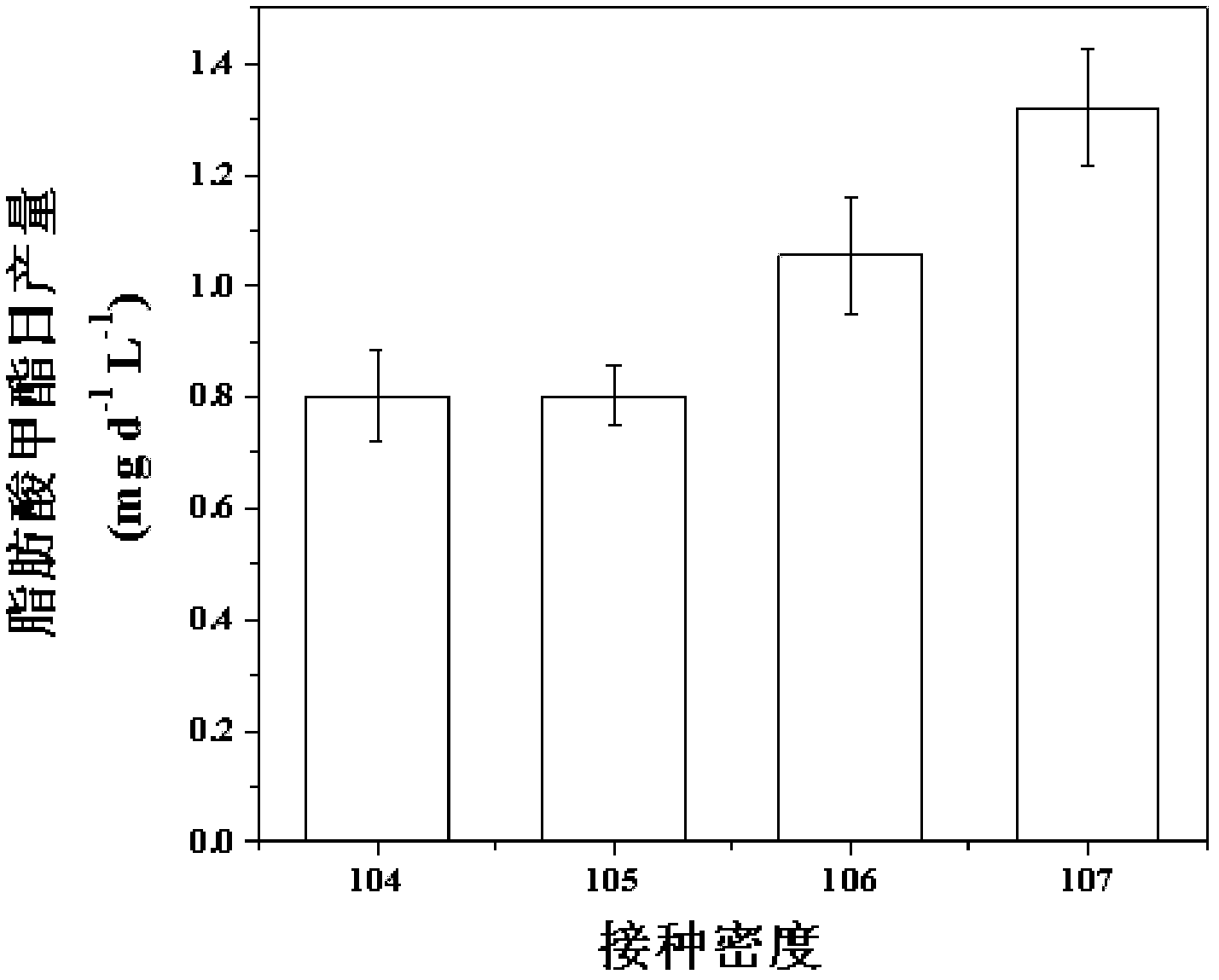

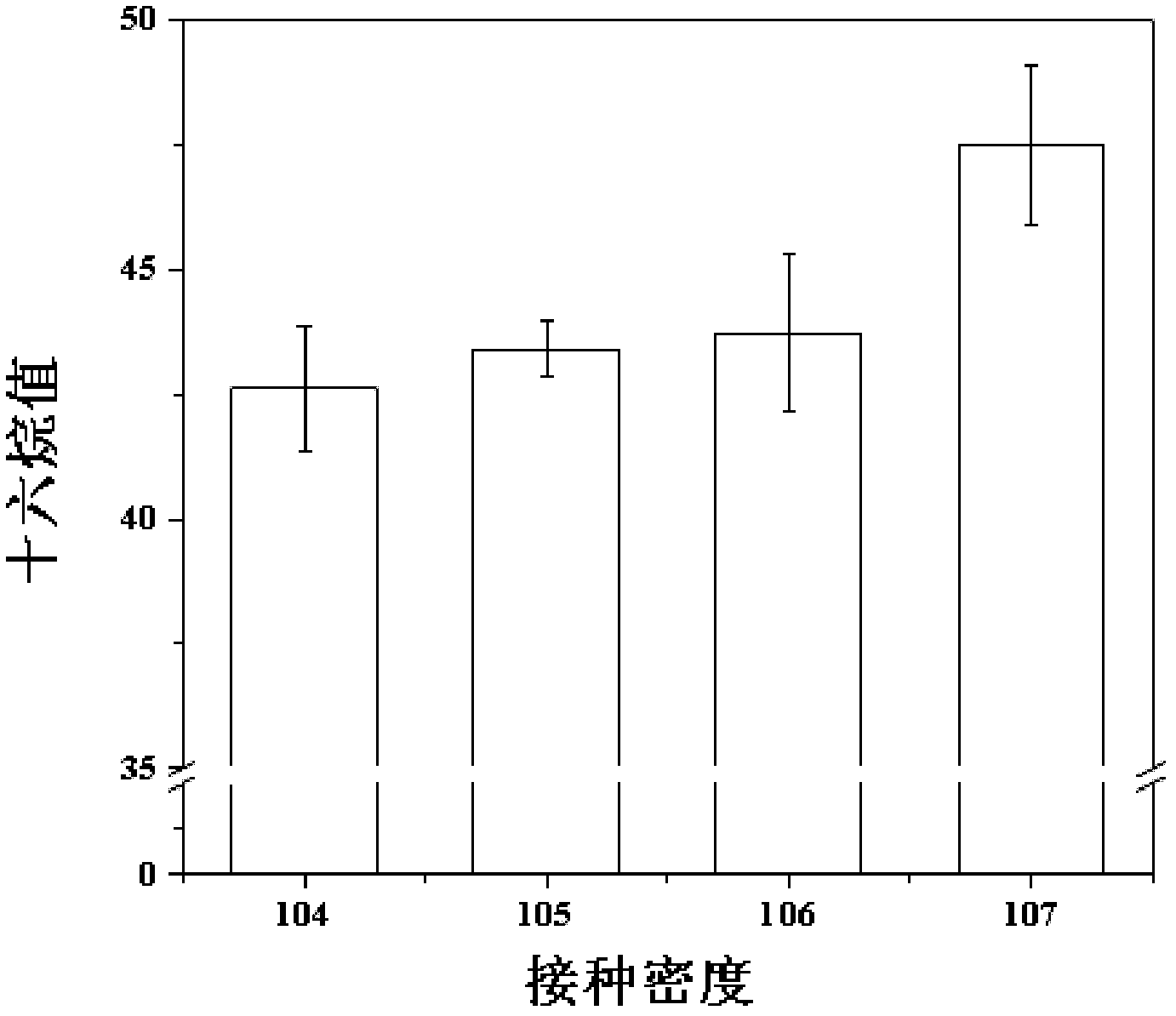

[0084] The microalgae were cultured at different inoculation densities, and the initial inoculation density was set to 1×10 4 , 1×10 5 , 1×10 6 and 1×10 7 cells mL -1 , when the cells were cultured to the stationary stage, 5 samples of algae liquid were taken out for each inoculation density, 100 mL each, centrifuged at 3000 rpm at 4 °C for 3 min, the cells in the lower layer were collected, and quenched with 4 mL of metabolic termination solution at -40 °C for 5 minutes, terminate the metabolic reaction, and freeze-dry at -80°C for 4 hours to obtain freeze-dried cells;

[0085] The metabolic termination solution contains 1500 mg·L -1 NaNO 3 , 36mg·L -1 CaCl 2 2H 2 O,...

Embodiment 2

[0149] A method utilizing metabolomics to improve microalgae culture conditions to increase oil production capacity of microalgae, comprising the steps of:

[0150] (1) Determination of intracellular metabolites in Chlorella sorokiniana:

[0151] ① Chlorella sorokiniana cell collection and quenching:

[0152] The microalgae were cultured at different inoculation densities, and the initial inoculation density was set to 1×10 4 , 1×10 5 , 1×10 6 and 1×10 7 cells mL -1 , when the cells are cultured to the late exponential and stable phases, take 4 algae liquid samples at each time point in each inoculation density, each 120mL, centrifuge at 5000rpm at 4°C for 3min, collect the cells in the lower layer, and use 3mL of metabolic stop solution Quench at -40°C for 7 minutes to terminate the metabolic reaction, and freeze-dry at -80°C for 6 hours to obtain freeze-dried cells;

[0153] Metabolism termination liquid is the same as embodiment 1;

[0154] ②Extract intracellular met...

Embodiment 3

[0187] A method utilizing metabolomics to improve microalgae culture conditions to increase oil production capacity of microalgae, comprising the steps of:

[0188] (1) Determination of intracellular metabolites in Chlorella sorokiniana:

[0189] ① Chlorella sorokiniana cell collection and quenching:

[0190] The microalgae were cultured at different inoculation densities, and the initial inoculation density was set to 1×10 4 , 1×10 5 , 1×10 6 and 1×10 7 cells mL -1 , when the cells are cultured to the mid-exponential, late-exponential and stable phases, take 3 algae liquid samples at each time point under each inoculation density culture, each 150mL, centrifuge at 3000rpm at 4°C for 4min, and collect the cells in the lower layer. Use 5mL of metabolic termination solution to quench at -40°C for 10 minutes to terminate the metabolic reaction, and freeze-dry at -80°C for 6 hours to obtain freeze-dried cells;

[0191] Metabolism termination liquid is the same as embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com