Anode electrode material, preparation method thereof, application and working method of anode electrode material in treating wastewater containing phenol by electrochemical oxidation

A technology of anode electrode and phenol wastewater, which is applied in the field of environmental pollution control to achieve the effects of simple removal device, effective treatment and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

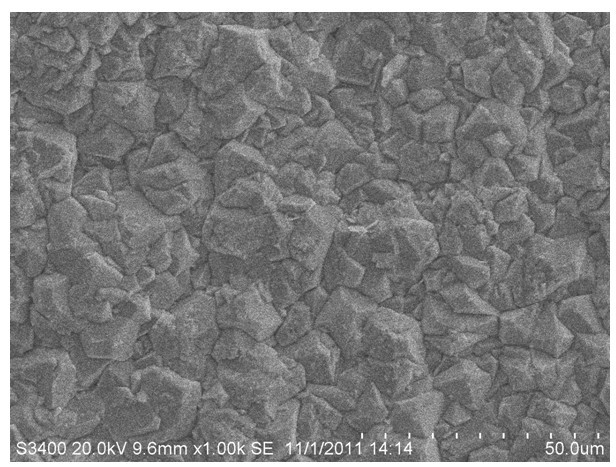

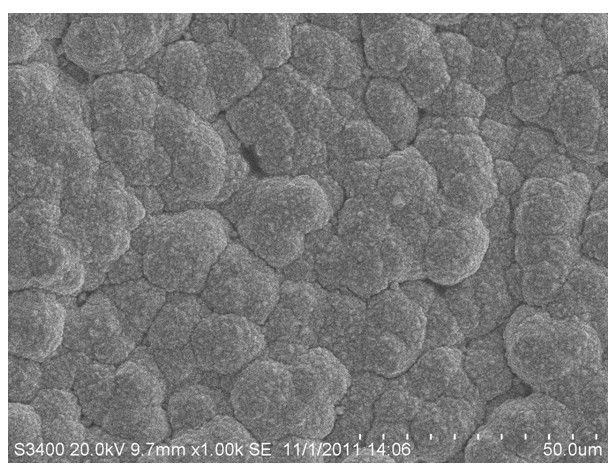

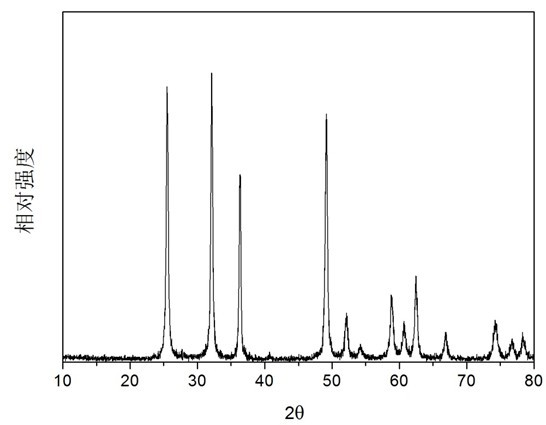

Image

Examples

Embodiment 1

[0042] 1) Grinding the titanium plate to make the surface of the titanium plate present a uniform light gray luster;

[0043] 2) Alkaline washing the polished titanium plate to remove the pollutants on the surface of the titanium plate;

[0044] 3) The titanium plate after alkali washing is pickled to remove TiO on the surface of the titanium plate 2 ;

[0045] 4) Use the titanium plate treated in step 3) as the anode, Pt as the cathode, and use 0.5 wt%NaF, 1 wt%Na 2 SO 4 , 5 wt% polyethylene glycol and ultrapure water were prepared as an electrolyte solution, etched at a constant voltage of 15 V for 1 hour, and then calcined in a muffle furnace at 500 ° C for 1.5 hours;

[0046] 5) Use Pt as the anode, and the titanium plate treated in step 4) as the cathode, 0.5mol / L (NH 4 ) 2 SO 4 Electrolyte, energized at a constant voltage of 1.5 V for 0.1 minute;

[0047] 6) Put the titanium plate treated in step 5) in 1 mol / L CuSO 4 The solution was treated with the pulse curren...

Embodiment 2

[0052] 1) Grinding the titanium plate to make the surface of the titanium plate present a uniform light gray luster;

[0053] 2) Alkaline washing the polished titanium plate to remove the pollutants on the surface of the titanium plate;

[0054] 3) The titanium plate after alkali washing is pickled to remove TiO on the surface of the titanium plate 2 ;

[0055] 4) Use the titanium plate treated in step 3) as the anode, Pt as the cathode, and use 2 wt%NaF, 5 wt%Na 2 SO20 wt% polyethylene glycol and ultrapure water were prepared as an electrolyte, etched at a constant voltage of 25 V for 3 hours, and then calcined in a muffle furnace at 550 °C for 3 hours;

[0056] 5) With Pt as the anode, the titanium plate treated in step 4) as the cathode, 1.5 mol / L (NH 4 ) 2 SO 4 Electrolyte, energized at a constant voltage of 2 V for 10 minutes;

[0057] 6) Put the titanium plate treated in step 5) in 2 mol / L CuSO 4 The solution was treated by pulse current method at 45 ℃ for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com