Rapid method for destroying structure of cathode-ray tube phosphor waste material

A cathode ray tube and fluorescent powder technology, applied in the field of rare earth resource recycling, can solve the problems of long leaching time, destruction of cathode ray tube fluorescent powder waste, up to several hours, etc., and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

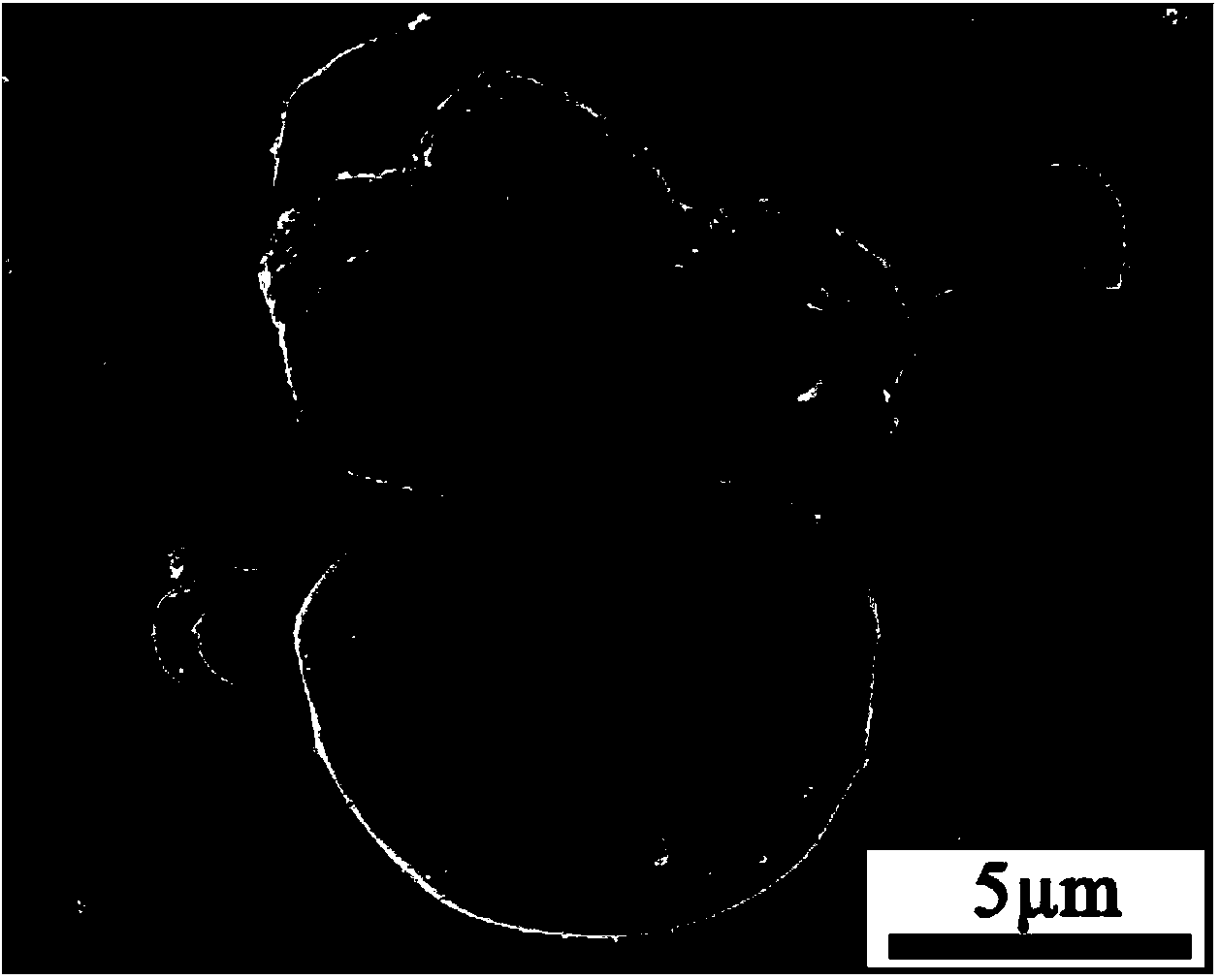

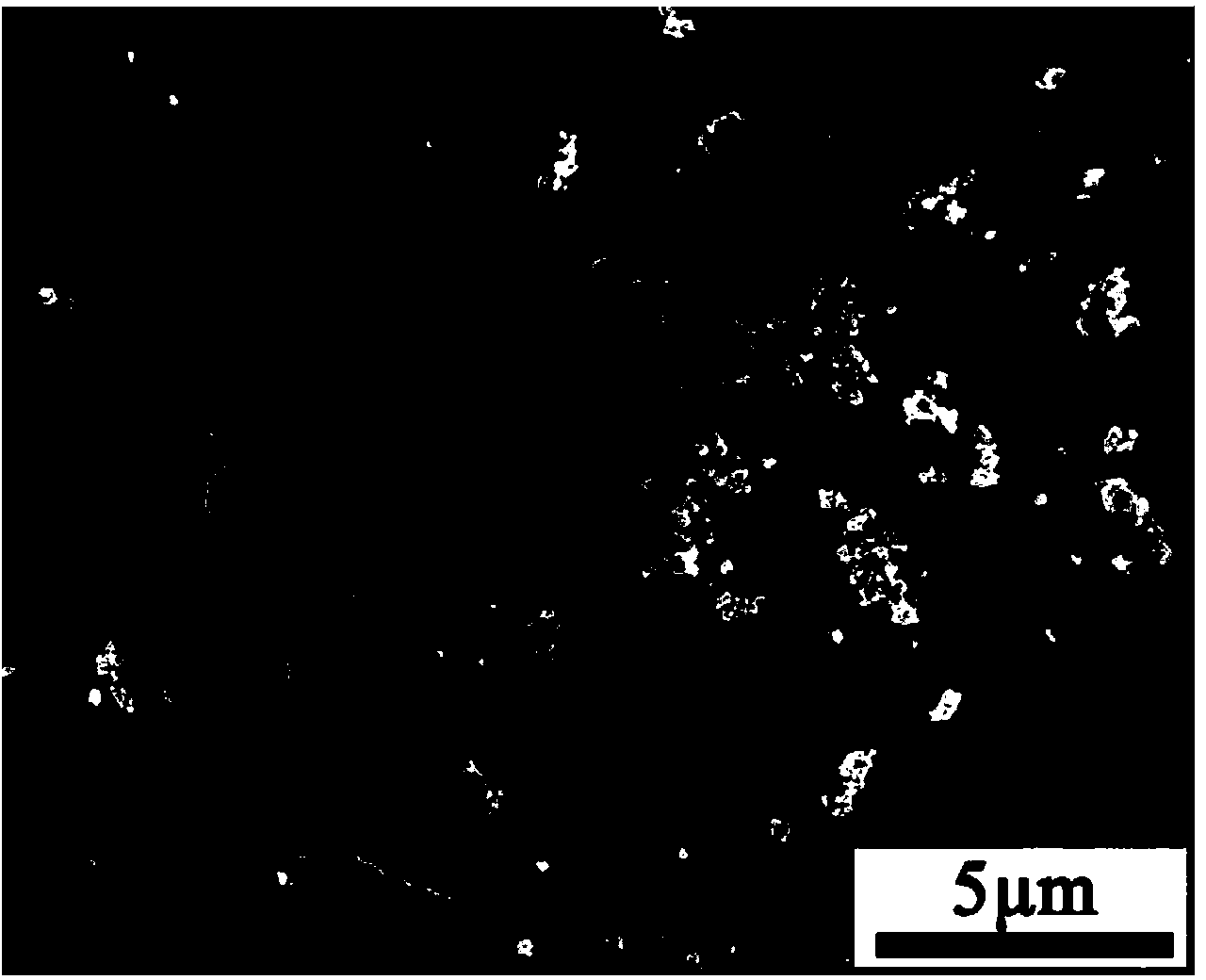

Image

Examples

Embodiment 1

[0016] The process and steps of this embodiment are as follows:

[0017] (1) Mechanical activation treatment: take 10g of cathode ray tube fluorescent powder waste and carry out mechanical activation through a planetary ball mill under wet grinding conditions. The amount of pure water added to the wet grinding is 30% of the weight of the powder, and the wet grinding time is 0.5 hours. The rotational speed of the wet grinding is 580 rpm, and activated cathode ray tube fluorescent powder waste is obtained after wet grinding.

[0018] (2) One-step high-temperature liquid-solid reaction: Take the activated cathode ray tube fluorescent powder waste obtained in step (1) and fully dry it in a drying oven, control the drying temperature at 105°C, and then fully mix it with a certain amount of alkali metal compound A high-temperature liquid-solid reaction was carried out in a tube furnace under an oxidizing atmosphere, the reaction time was controlled for 10 minutes, and the reaction t...

Embodiment 2

[0023] The process and steps of this embodiment are as follows:

[0024] (1) Mechanical activation treatment: Take 10g of cathode ray tube fluorescent powder waste and carry out mechanical activation through a planetary ball mill under wet grinding conditions. The amount of pure water added to the wet grinding is 60% of the weight of the powder, and the wet grinding time is 2 hours. The wet milling speed is 500 rpm, and activated cathode ray tube fluorescent powder waste is obtained after wet milling.

[0025] (2) One-step high-temperature liquid-solid reaction: Take a certain amount of activated cathode ray tube fluorescent powder waste obtained in step (1) and fully dry it in a drying oven. The drying temperature is controlled at 110°C, and then fully mixed with a certain amount of alkali metal compound. Put it into a tube furnace for one-step high-temperature liquid-solid reaction under an oxidizing atmosphere, control the reaction time for 3 minutes, and control the reacti...

Embodiment 3

[0029] The process and steps of this embodiment are as follows:

[0030] (1) Mechanical activation treatment: Take 10g of cathode ray tube fluorescent powder waste and carry out mechanical activation through a planetary ball mill under wet grinding conditions. The amount of pure water added to the wet grinding is 40% of the weight of the powder, and the wet grinding time is 1.5 hours. The rotational speed of the wet grinding is 580 rpm, and activated cathode ray tube fluorescent powder waste is obtained after wet grinding.

[0031] (2) One-step high-temperature liquid-solid reaction: Take a certain amount of activated cathode ray tube fluorescent powder waste obtained in step (1) and fully dry it in a drying oven. The drying temperature is controlled at 110°C, and then fully mixed with a certain amount of alkali metal compound. Put it into a tube furnace for one-step high-temperature liquid-solid reaction under an oxidizing atmosphere, control the reaction time for 5 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com