Application of three-dimensional ordered macro-porous perovskite type oxide in preparing hydrogen through carbonic fuel chemical chain

A perovskite-type, three-dimensional ordered technology, applied in inorganic chemistry, bulk chemical production, chemical instruments and methods, etc., can solve problems such as no reports, and achieve simple process, high reactivity, performance and service life improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

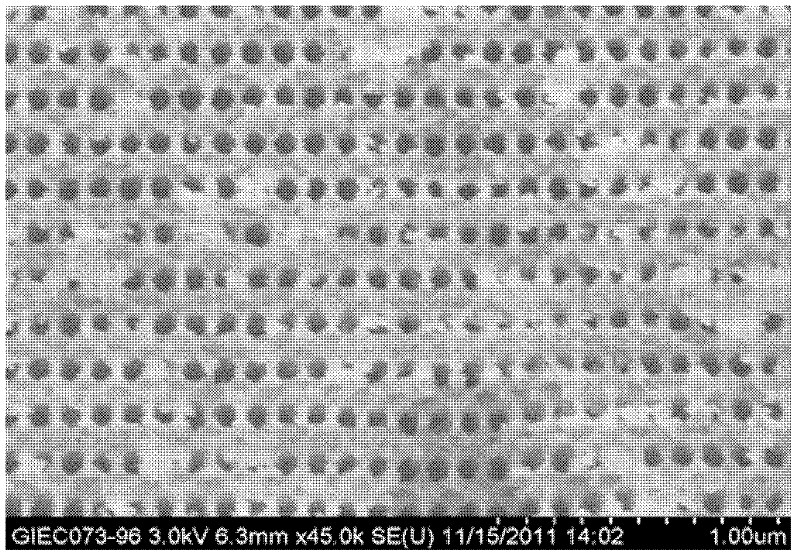

[0023] Example 1: Preparation method of PS colloidal crystal template.

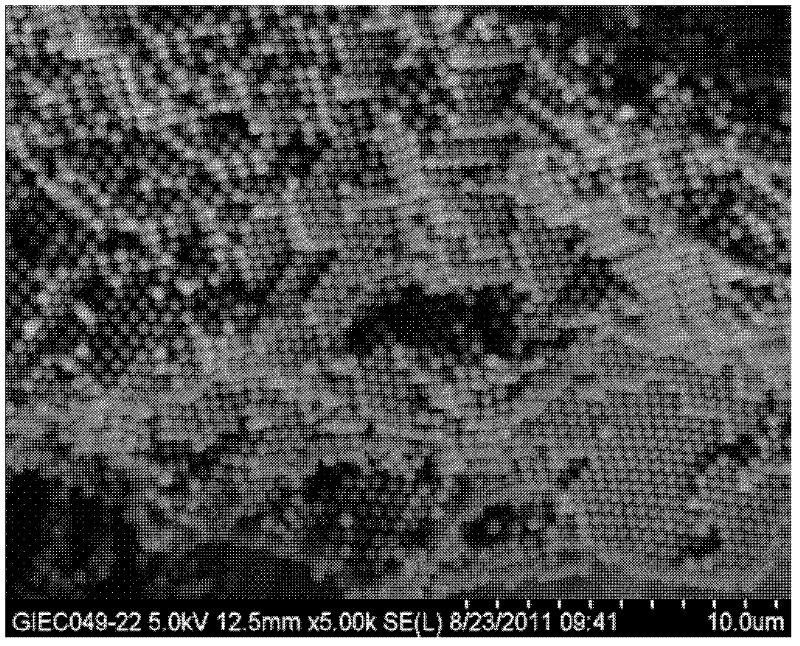

[0024] In the present embodiment, adopt the following method to prepare PS colloidal crystal mold: in house agitator, reflux condenser, thermometer and N 2 Add 1000ml of deionized water to the 2000ml four-neck flask of the trachea, pass N 2Vacuumize and heat to 70°C; slowly add 150ml of styrene purified by vacuum distillation into deionized water heated to 70°C; weigh 0.38g of potassium persulfate, dissolve it in 35ml of deionized water, and heat in a water bath to 70°C After injecting into the reaction solution at ℃, react at a stirring speed of 200r / min and under the protection of nitrogen for 24h; filter the obtained reaction solution to remove larger aggregates, then place it in a centrifuge tube and centrifuge at 1000r / min for 20h. The supernatant was discarded, and the tightly arranged colloidal crystal template was obtained, and the SEM picture of it is shown in figure 1 shown.

Embodiment 2

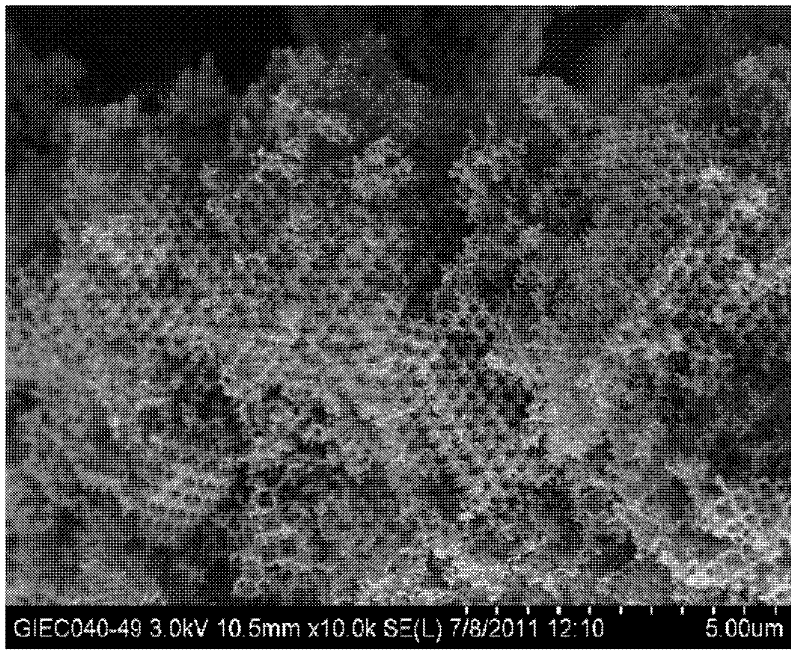

[0025] Example 2: Three-position ordered macroporous perovskite-type oxygen carrier LaFeO 3 preparation of

[0026] Three-dimensional ordered macroporous perovskite-type oxygen carrier LaFeO was prepared by the following method 3 : Weigh lanthanum nitrate and ferric nitrate at a molar ratio of 1:1 and dissolve them in 15ml of ethanol, control the metal ion concentration at about 1mol / L, stir at room temperature; add citric acid according to the molar ratio of the total metal salt to citric acid at 1:1 As a complexing agent, add an appropriate amount of ethylene glycol to adjust the viscosity of the solution, and stir for 2 hours to obtain LaFeO 3 precursor solution; 5g of the dried PS colloidal crystal template was pretreated at 110°C for 10min to improve the mechanical strength of the template and the connectivity of the pore structure, and then immersed in the precursor solution for 5h, the excess solution Remove by suction filtration, and the template is vacuum-dried; in ...

Embodiment 3

[0028] Example 3: Three-position ordered macroporous perovskite oxygen carrier EuFeO 3 preparation of

[0029] Weigh europium nitrate and ferric nitrate at a molar ratio of 1:1 and dissolve them in 15ml of ethanol, and control the metal ion concentration at about 1mol / L; add citric acid as a complexing agent according to the molar ratio of the total metal salt to citric acid at 1:1 , and then add an appropriate amount of ethylene glycol to adjust the viscosity of the solution; the dipping and roasting process is the same as in Example 2.

[0030] XRD results ( image 3 ) shows that the prepared EuFeO 3 It is a perovskite oxide, and its morphology was observed by scanning electron microscopy (SEM) ( Figure 5 ), with a three-dimensional ordered macroporous structure. The activity evaluation results for chemical looping hydrogen production from carbon-containing fuels are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com