Heat compounding technique and apparatus of BOPET film and tin-free steel plate

A thermal lamination and steel plate technology, applied in layered products, lamination devices, lamination, etc., can solve the problems of endangering human health, pollution and energy consumption, and achieve environmental protection in the production process and products, low production costs, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] specific implementation

[0052] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

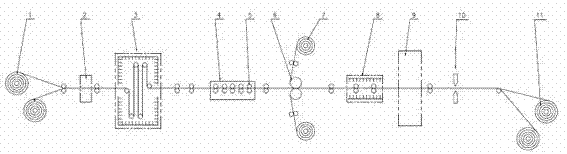

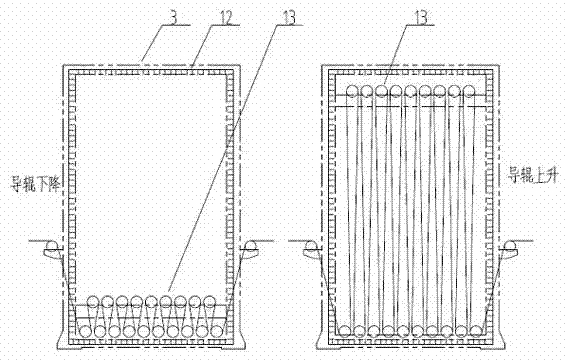

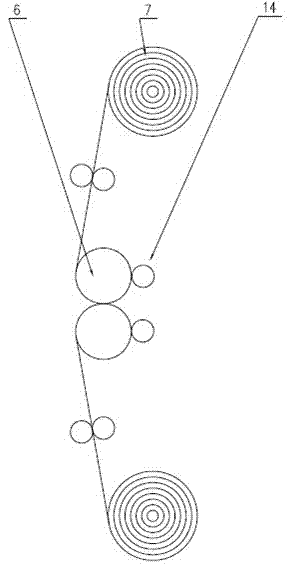

[0053] figure 1 It is a schematic diagram of the overall process and equipment process of an embodiment of the thermal lamination process and equipment of BOPET film and tin-free steel plate of the present invention. The entire production process of an embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings of the present invention.

[0054] Tin free steel (TFS for short), that is, the surface of cold-rolled thin steel plate is not tin-plated, but a thin layer of chromium and chromium oxide is plated on the surface of the steel plate by electroplating. Compared with tinplate, TFS is non-toxic and more environmentally friendly, and TFS has better adhesion to film. BOPET film is a biaxially oriented polyester film, which has the advantages of high str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com