Laser shock high molecular polymer indirect micro-forming method and dedicated device thereof

A polymer, laser shock technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of reducing the strength and life of the mold, ablation of the surface of the parts, mold damage, etc., to reduce the phenomenon of dilution, Improve part quality and avoid ablation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

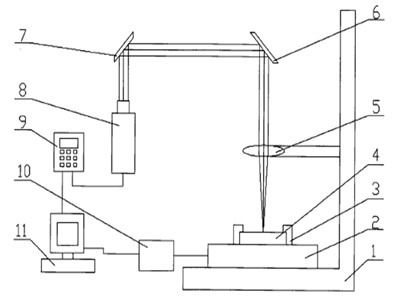

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

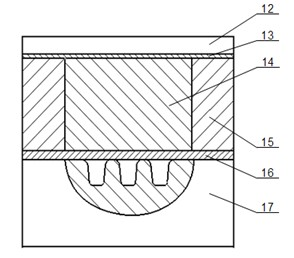

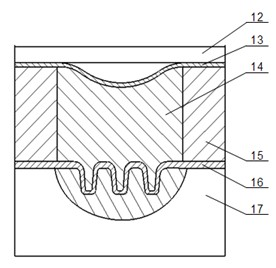

[0018] see figure 1 , The special device for indirect micro-forming of laser shock polymers of the present invention is composed of a laser loading system, a forming system and a control system. Among them, the laser loading system includes a nanosecond laser 8, a first reflector 7, a second reflector 6 and a focusing lens 5. The nanosecond laser 8 is equipped with an indicating light system, and the laser light emitted by it passes through the first reflector 7 and the second reflector in sequence. After reflection by the two reflectors 6, the optical path is changed to reach the focusing lens 5. The forming system includes a sample system 4, a clamp body 3, a three-dimensional mobile platform 2 and an L-shaped base 1, wherein the sample system 4 is arranged directly under the focusing lens 5, and the laser focused by the focusing lens 5 acts on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com