Method for constructing ocean sediment microbial fuel battery with high output voltage and high output power

A seabed deposition and fuel cell technology, applied in the direction of biochemical fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems that cannot meet the needs of instruments, low output voltage, and BMFC cannot be boosted in series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

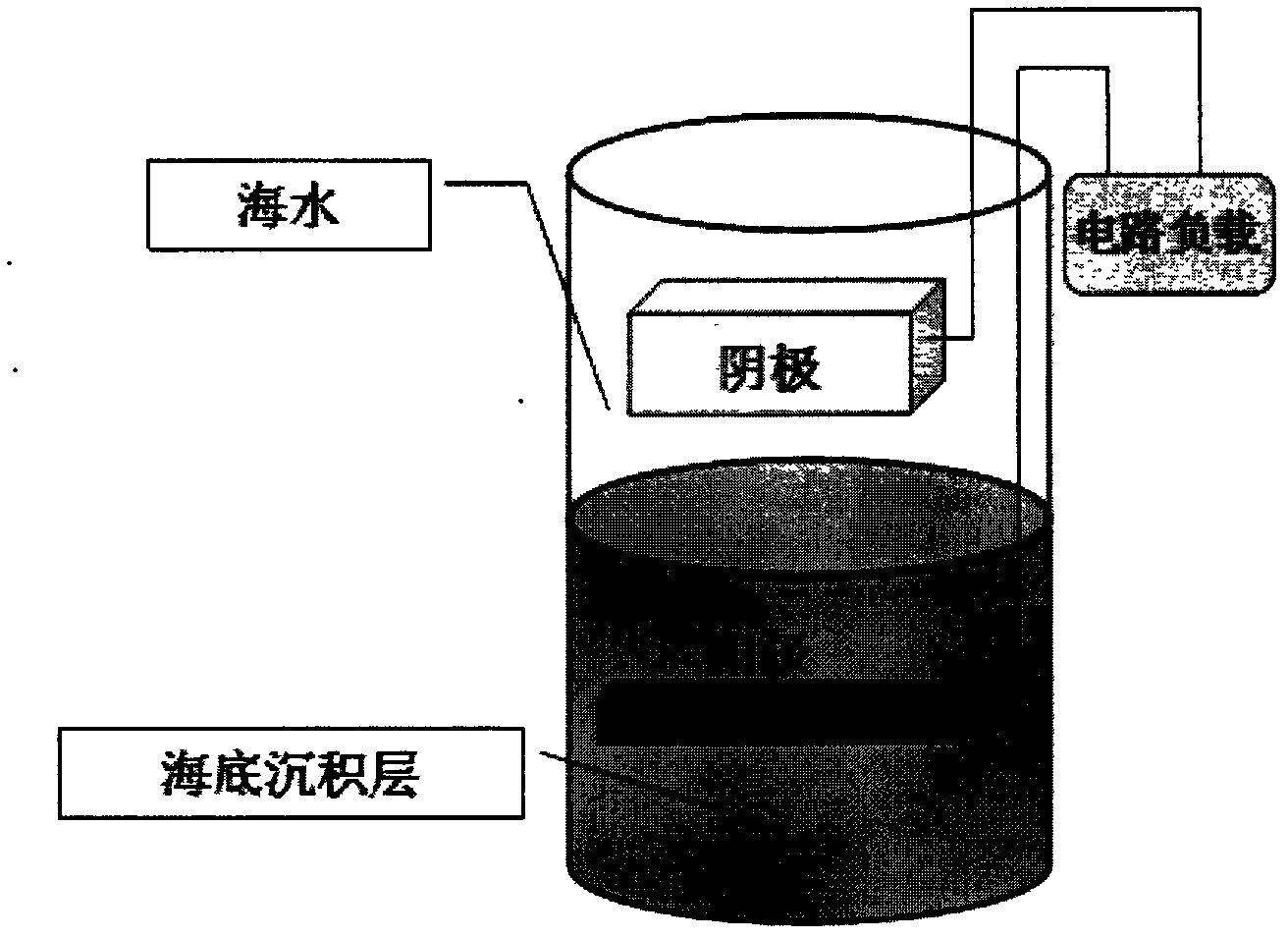

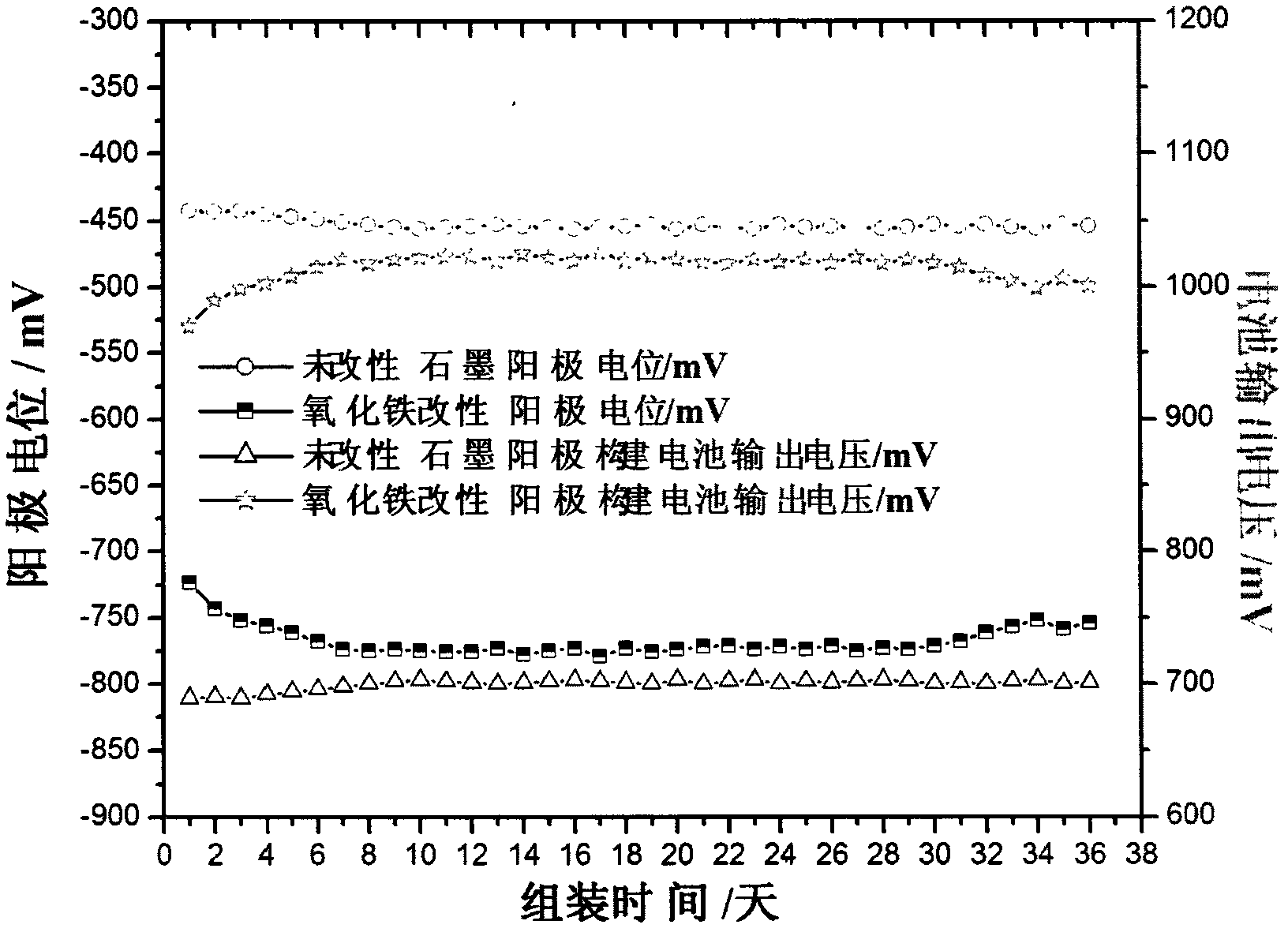

[0039] Example 1: This example is used to prepare a low-potential anode modified by electrolytic deposition of iron oxide.

[0040] Take 30g FeCl 3 ·6H 2 O. Add 400mL of distilled water into a 500mL beaker, heat up to 50-70°C and stir quickly until the iron salt is completely dissolved, the solution is brownish red, then cool to 20°C, transfer the solution in the beaker to a 500mL volumetric flask, and then use a small amount of Rinse the beaker with distilled water, introduce the rinsing solution into the volumetric flask, and then set the volume of the volumetric flask to the 500mL mark. Grind rod-shaped graphite (7cm×Φ0.9cm) with 100, 240, 360, 600, and 800 mesh sandpaper in sequence, then sonicate in ethanol for 10-20min, then in distilled water for 10-20min, take it out and dry it, and put the rod-shaped conductive substrate It is connected with the wire, and the connection between the wire and the substrate is sealed with epoxy resin. The rod-shaped conductive substra...

Embodiment 2

[0041] Example 2: This example is used to prepare a low-potential anode modified by electrolytic deposition of iron oxide.

[0042] Take 15g FeCl 2 4H 2 O. Add 400mL of distilled water into a 500mL beaker, heat up to 50-70°C and stir quickly until the iron salt is completely dissolved, then cool to 20°C, transfer the solution in the beaker to a 500mL volumetric flask, rinse the beaker with a small amount of distilled water, and The rinsing solution is introduced into the volumetric flask, and then the volumetric flask is set to the 500mL mark. Polish the dendritic graphite electrode with 100, 240, 360, 600, and 800 mesh sandpaper in sequence, then sonicate in ethanol for 10 minutes, then in distilled water for 10 minutes, take it out and dry it, connect the electrode to the wire, and use a ring at the connection between the wire and the substrate Oxygen resin seal. The dendritic graphite electrode is used as the working electrode, the rod-shaped graphite electrode is used a...

Embodiment 3

[0043] Example 3: This example is used to prepare a low-potential anode modified by electrolytic deposition of iron oxide.

[0044] Take 25g FeCl 3 ·6H 2 O and 12g FeCl 2 4H 2 O. Add 400mL of distilled water into a 500mL beaker, raise the temperature to 50°C and stir quickly until the iron salt is completely dissolved, then cool to 20°C, transfer the solution in the beaker to a 500mL volumetric flask, rinse the beaker with a small amount of distilled water, and dissolve the rinse solution Import into the volumetric flask, and then make the volumetric flask to the 500mL mark. Grind the disc-shaped graphite electrode with 100, 240, 360, 600, and 800 mesh sandpaper in sequence, then sonicate in ethanol for 10 minutes, then in distilled water for 10 minutes, take it out and dry it, connect the conductive substrate to the wire, and connect the wire to the substrate Seal with epoxy. Use the disc-shaped graphite electrode as the working electrode, and the rod-shaped graphite ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com