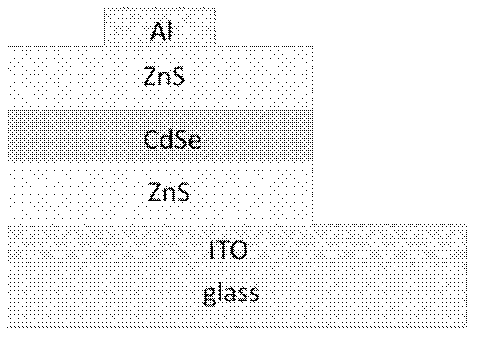

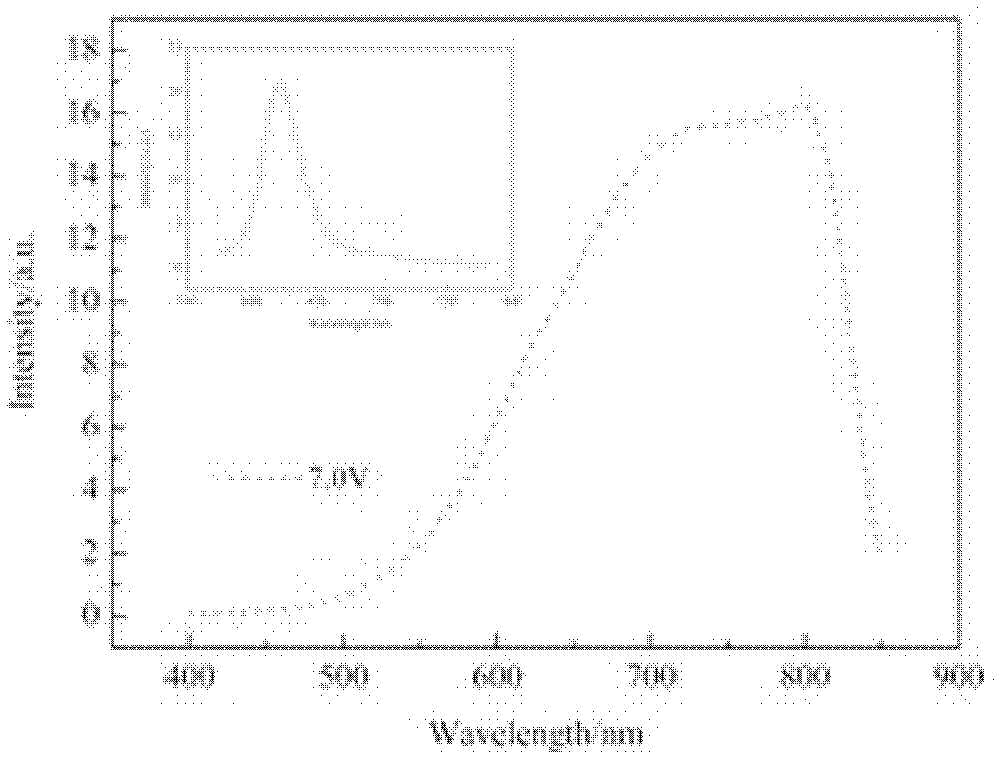

Manufacturing method for indium tin oxide (ITO)/zinc sulfide (ZnS)/cadmium selenide (CdSe)/ZnS/aluminum (Al) structure with visible light and near-infrared luminescence emission characteristics

A technology of emission characteristics and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of device stability and life, and achieve the effects of wide emission wavelength range, low turn-on voltage, and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in further detail below by specific embodiments:

[0025] (1) Preparation of ITO substrate.

[0026] The ITO substrate is purchased from the market, the thickness of ITO is 60nm, and it needs to be cleaned and degassed before growth.

[0027] (2) The first layer of ZnS film is grown by thermal evaporation.

[0028] The ZnS film was grown at room temperature with a thickness of 150nm and a growth pressure of 4×10 -3 Pa.

[0029] (3) Spin-coat CdSe quantum dots with a thickness of 500nm and allow them to air-dry naturally.

[0030] (4) The second layer of ZnS film is grown by thermal evaporation.

[0031] The ZnS film was grown at room temperature with a thickness of 150nm and a growth pressure of 4×10 -3 Pa.

[0032] (5) Thermal evaporation Al electrode.

[0033] A 200nm Al thin film was grown at room temperature as an electrode layer.

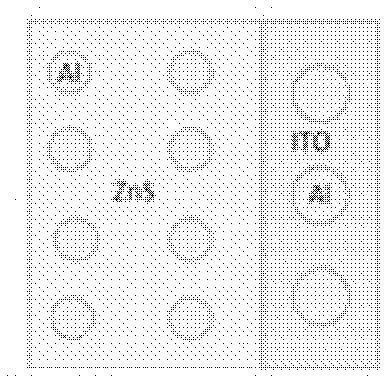

[0034] (6) Photolithography to form electroluminescent device patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com