Etching liquid for displaying void type defects of heavy-doped N-type Czochralski silicon single crystal

A technology of Czochralski silicon and etching solution, which is used in the preparation of test samples, optical test flaws/defects, etc., can solve problems such as unsuitable silicon single crystal, and achieve regular morphology, fast corrosion rate, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

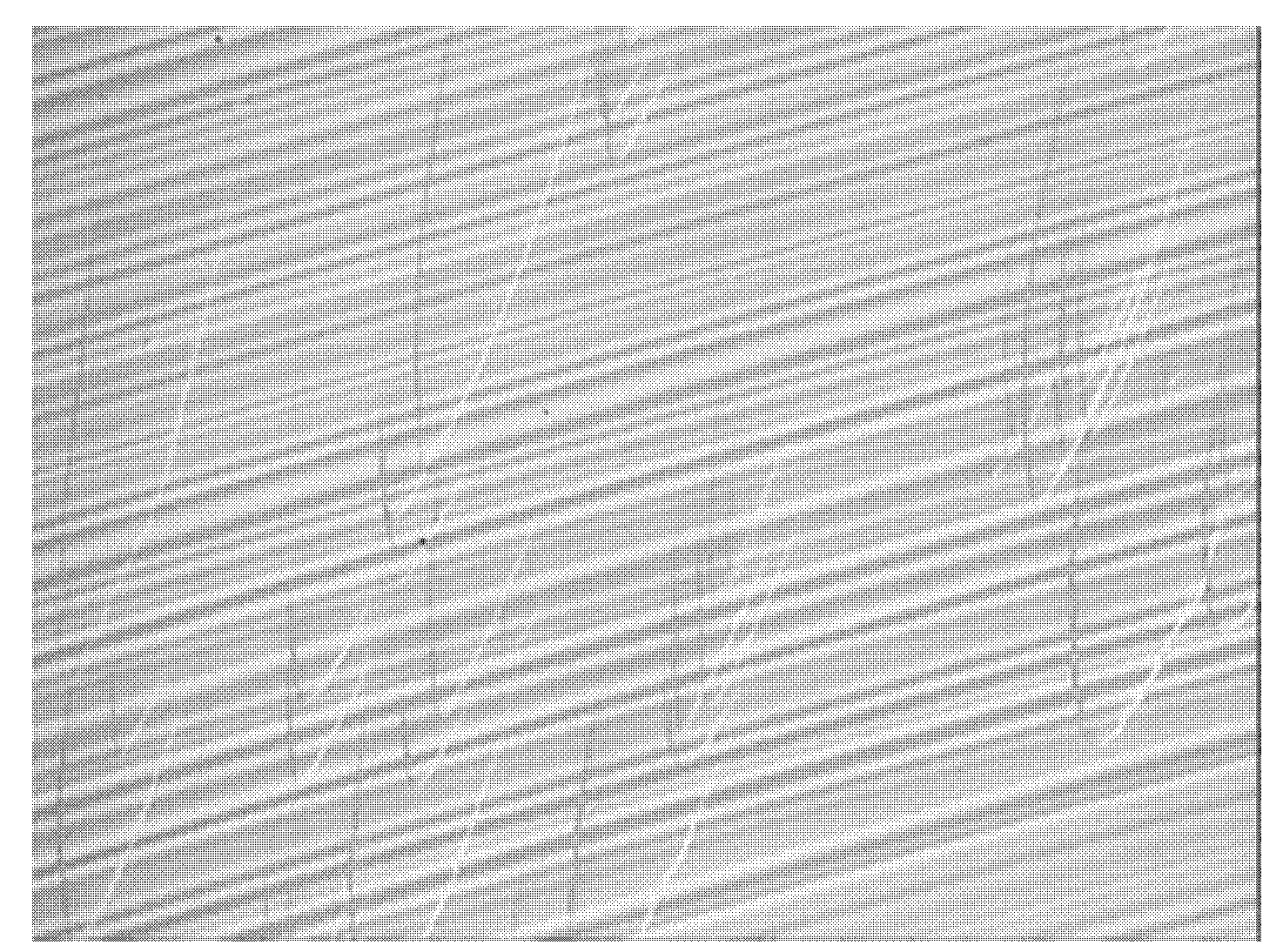

[0035] Example 1 Using an etchant to show void-type defects in a Czochralski silicon single crystal heavily doped with arsenic in the crystal orientation

[0036] The silicon wafer is a Czochralski silicon single crystal heavily doped with arsenic in the crystal direction, and its doping concentration is 1.6×10 19 cm -3 , the resistivity is 4.0mΩ·cm.

[0037] Preparation of corrosion solution: prepare chromium trioxide solution with a molar concentration of 0.2mol / L and hydrofluoric acid with a mass concentration of 40% respectively; according to the volume ratio of 1:1, use a graduated cylinder to measure hydrofluoric acid and add it to the chromium trioxide solution In, mix well.

[0038] Etching solution is used for the display of void-type defects on silicon wafers, and the specific steps include:

[0039] (1) Clean the silicon wafer with RCA standard cleaning solution;

[0040] (2) Put the beaker with the corrosive solution in a constant temperature water bath at 30...

Embodiment 2

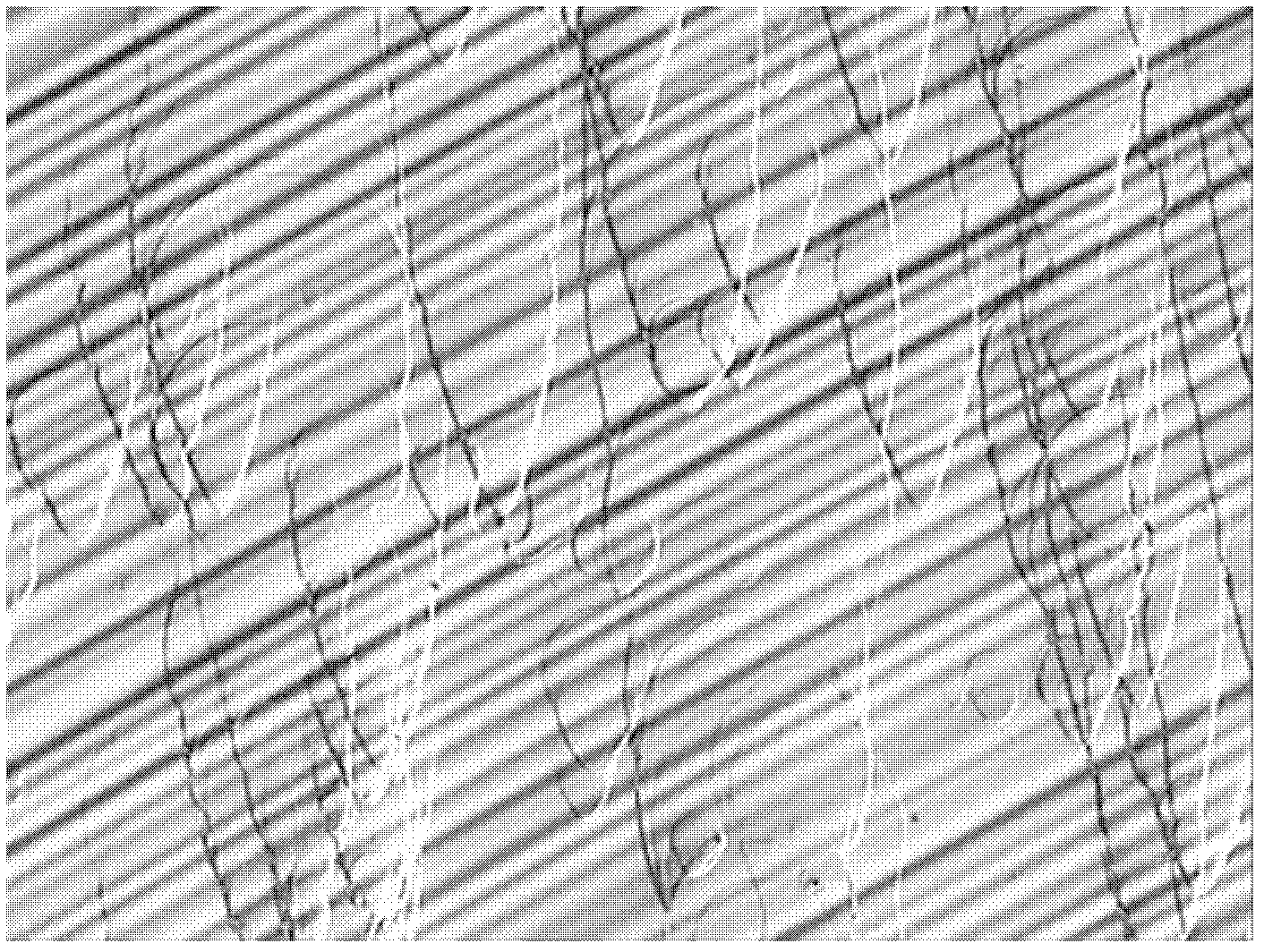

[0048] Example 2 Using Etching Solution to Display Cavity Defects in the Crystal Orientation Heavy Phosphorus-doped Czochralski Silicon Single Crystal

[0049] The silicon wafer is a Czochralski silicon single crystal heavily doped with phosphorus in the crystal direction, and its doping concentration is 7.4×10 19 cm -3 , the resistivity is 1.0mΩ·cm.

[0050] Preparation of corrosion solution: prepare chromium trioxide solution with a molar concentration of 0.2mol / L and hydrofluoric acid with a mass concentration of 40% respectively; according to the volume ratio of 1:1, use a graduated cylinder to measure hydrofluoric acid and add it to the chromium trioxide solution In, mix well.

[0051] The etchant is used for the display of void-type defects on silicon wafers. The specific steps are the same as those in Example 1. The defect morphology after being photographed by an optical microscope is shown in image 3 .

Embodiment 3

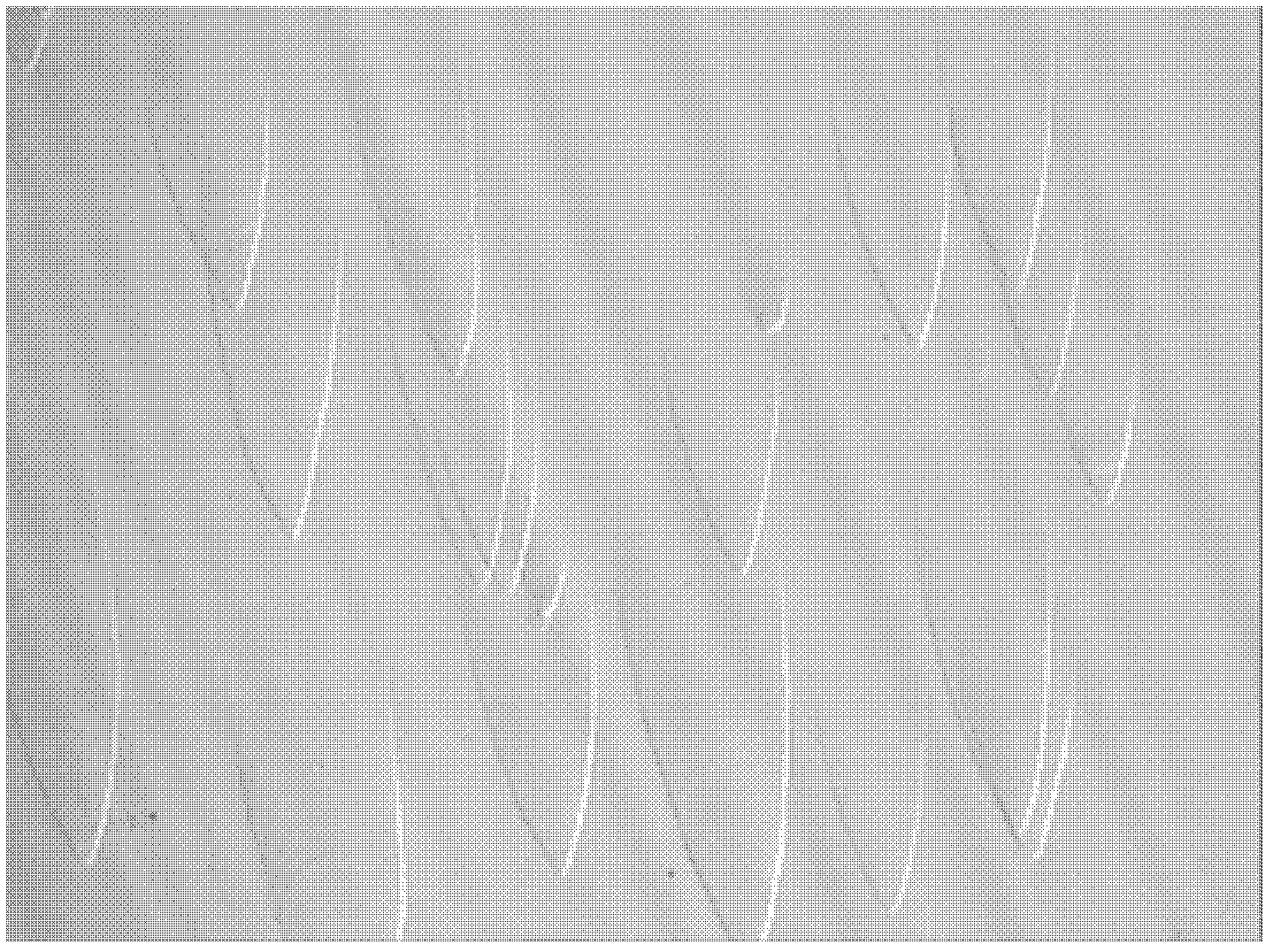

[0055] Example 3 Using Etching Solution to Display Cavity Type Defects in the Crystalline Heavily Doped Phosphorous Czochralski Silicon Single Crystal

[0056] The silicon wafer is a Czochralski silicon single crystal heavily doped with phosphorus in the crystal direction, and its doping concentration is 1.1×10 20 cm -3 , the resistivity is 0.7mΩ·cm.

[0057] Preparation of corrosion solution: prepare chromium trioxide solution with a molar concentration of 0.2mol / L and hydrofluoric acid with a mass concentration of 40% respectively; according to the volume ratio of 1:1, use a graduated cylinder to measure hydrofluoric acid and add it to the chromium trioxide solution In, mix well.

[0058] Etching solution is used for the display of void-type defects on silicon wafers, and the specific steps are the same as those in Example 1; Figure 5 .

[0059] Depend on Figure 5 It can be seen that after the silicon wafer is etched by this embodiment, the defects of the flow patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com