Helicopter composite material paddle fatigue test piece molding method

A composite material and molding method technology, which is used in the testing of mechanical parts, the testing of machine/structural parts, and the preparation of samples for testing, etc. Leaf scrap and other problems, to ensure stability and smoothness, improve the pass rate of one-time inspection, and shorten the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] 1. Blade cutting, hollowing out

[0080] Remove the iron covering from the formed molded blade, and draw the blade cutting reference line Zx on the blade according to the design requirements, taking the 0-section position of the blade as the reference 1 、Zx 2 , cut off the molded paddle according to the reference line and remove the burrs, and hollow out the foam in the inner cavity of the end of the molded paddle according to the design requirements;

[0081] 2. Paddle filling

[0082] Fill the cavity at the end of the specimen with the chopped fiber mixture, remove air bubbles, and smooth it. Tape the foam blocks at the ends to prevent the flow of the chopped fiber mixture, waiting to cure;

[0083] 3. Paste the vacuum bag, solidify, open the mold

[0084] Curing: heat up to 100±5°C and keep the temperature constant for 6 hours

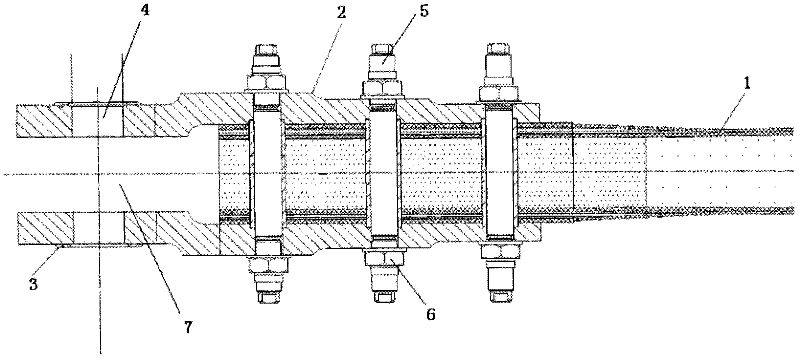

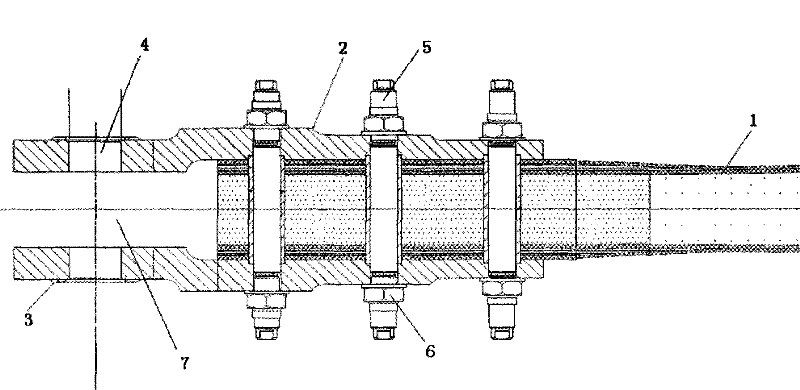

[0085] 4. Drilling holes for paddle 1

[0086] Use the fatigue test piece drilling jig to determine the hole position required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com