Equipment and process for producing light tar by controlling QI (Quality Index) value of tar

A technology of light tar and tar, which is applied in the processing of tar, petroleum industry, heating of coke ovens, etc., can solve the problems of waste of resources and the extraction of light tar that cannot be processed, and achieves lower production costs, far-reaching environmental protection, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

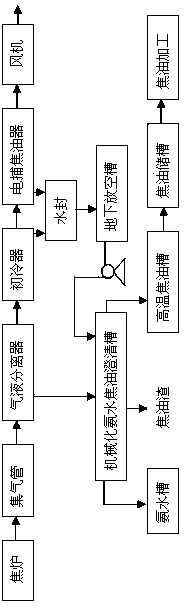

[0017] Such as figure 2 As shown, an equipment for producing light tar by controlling the original QI value of tar, including a coke oven, a gas collecting pipe connected with the coke oven, a gas-liquid separator connected with the gas collecting pipe, and a mechanized gas-liquid separator connected with the gas-liquid separator Ammonia tar clarification tank and primary cooler, ammonia water tank and high-temperature tar tank connected to mechanized ammonia tar clarification tank, tar storage tank connected to high-temperature tar tank, tar processing device connected to tar storage tank, and primary cooling The electric tar catcher connected with the electric tar catcher, the fan connected with the electric tar catcher, the water seal arranged under the primary cooler and the electric tar catcher, the mechanized ammonia tar clarification tank connected with the water seal, the water The seal is connected with the condensate tank, and the condensate tank is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com