Novel hydrophobic modified nano-silicon material

A technology of hydrophobic modification and nano-silicon, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high price, high cost, hidden dangers, etc., and achieve the effect of high transparency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

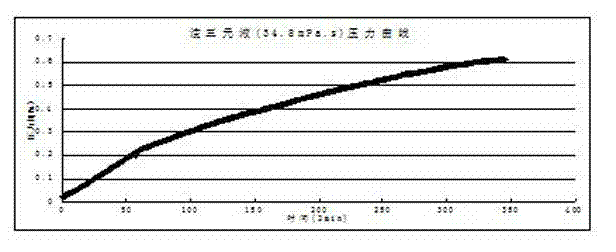

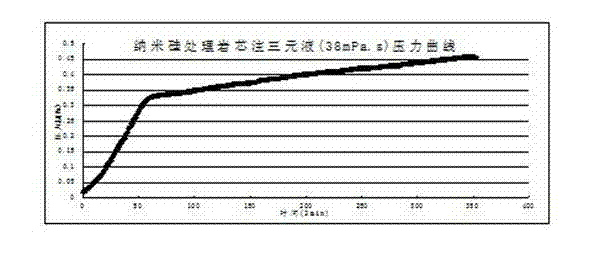

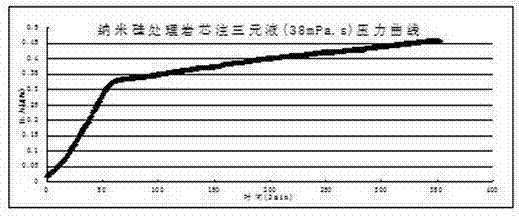

Image

Examples

Embodiment 1

[0011] Add 100 grams of water-dispersed nano-silicon (Jiangsu Yutong Chemical Co., Ltd.) into absolute ethanol to make the concentration of nano-silicon reach 5%, stir for 30 minutes, heat up to 45°C, and add kh550 type silane coupler dropwise at a ratio of 2% of the mass of nano-silicon. Joint agent (Nanjing Aocheng Chemical Co., Ltd.) ethanol solution, the concentration of the solution is 1%, stir for 4 hours, adjust the pH value to 8 with NaOH, continue stirring for 30 minutes, raise the temperature to 45°C, and add 1% dropwise Octadecyltrimethoxysilane (Hangzhou Sloan Materials Co., Ltd.) ethanol solution 20ml, and kept at constant temperature for 45 minutes, then stirred and reacted for 6 hours to obtain a hydrophobically modified nano silicon ethanol aqueous solution product.

[0012] Below by the wetting angle measuring instrument, the product of embodiment 1 is measured on the effect of the core slice at different concentrations, and the wetting effect of the hydrophobi...

Embodiment 2

[0021] Add water-dispersed nano-silicon to absolute ethanol to make the concentration of nano-silicon reach 1%, stir for 30 minutes, heat up to 45°C, add dropwise kh550 silane coupling agent ethanol solution with 0.5% nano-silicon mass, and stir for 4 hours; Adjust the pH value to 8, stir for 30 minutes, heat up to 45°C, add 10ml of 1% hexadecyltrimethoxysilane ethanol solution dropwise, and keep the temperature for 45 minutes, then stir and react for 4 hours to obtain hydrophobic modification Nano silicon ethanol aqueous solution product.

Embodiment 3

[0023] Add water-dispersed nano-silicon to absolute ethanol to make the concentration of nano-silicon reach 3%, stir for 30 minutes, heat up to 45°C, add dropwise kh550 silane coupling agent ethanol solution with 1% nano-silicon mass, and stir for 4 hours; Adjust the pH value to 8, stir for 30 minutes, heat up to 45°C, add 15ml of 1% hexadecyltrimethoxysilane ethanol solution dropwise, and keep the temperature for 45 minutes, then stir and react for 4 hours to obtain hydrophobic modification Nano silicon ethanol aqueous solution product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com