Organic cross linking system for polymer flooding and preparation method of cross linking agent

A cross-linking system and organic technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of transition metal human body and environmental damage, inability to meet environmental protection requirements, easy-to-break glue shrinkage, etc. and strength controllable, good synergistic stabilization effect, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

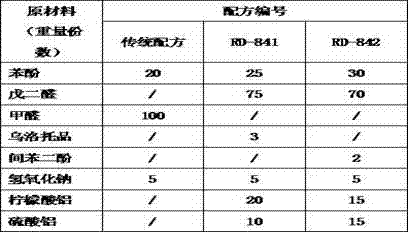

[0015] In the 2m equipped with stirrer, thermometer and heating mantle 3 In a stainless steel reaction kettle, add 250kg phenol, 35kg sodium hydroxide and 30kg urotropine, raise the temperature to 50°C, react at a constant temperature for 30 minutes, add 500kg glutaraldehyde, raise the temperature to 60°C, react at a constant temperature for 50 minutes, then add 15kg of sodium hydroxide , 200kg of aluminum citrate and 100kg of aluminum sulfate, heated up to 70°C, and reacted at a constant temperature for 20 minutes, and finally added 250kg of glutaraldehyde, raised the temperature to 90°C, and reacted at a constant temperature for 30 minutes. After the material is cooled, the material is discharged to obtain the product. The detailed formula is shown in Table 1, formula number RD-841.

Embodiment 2

[0017] In the 2m equipped with stirrer, thermometer and heating mantle 3 In a stainless steel reaction kettle, add 300kg phenol and 35kg sodium hydroxide, raise the temperature to 50°C, react at a constant temperature for 30 minutes, add 500kg glutaraldehyde and 20kg resorcinol, raise the temperature to 60°C, react at a constant temperature for 50 minutes, then add 15kg of sodium hydroxide 150kg of aluminum citrate and 150kg of aluminum sulfate, heated up to 70°C, and reacted at a constant temperature for 20 minutes, and finally added 200kg of glutaraldehyde, raised the temperature to 90°C, and reacted at a constant temperature for 30 minutes. After the material is cooled, the material is discharged to obtain the product. The detailed formula is shown in Table 1, formula number RD-842.

[0018] Table I

[0019]

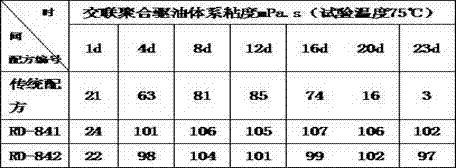

[0020] Table II

[0021]

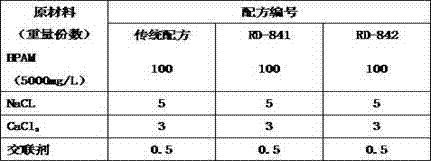

[0022] Table three

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com