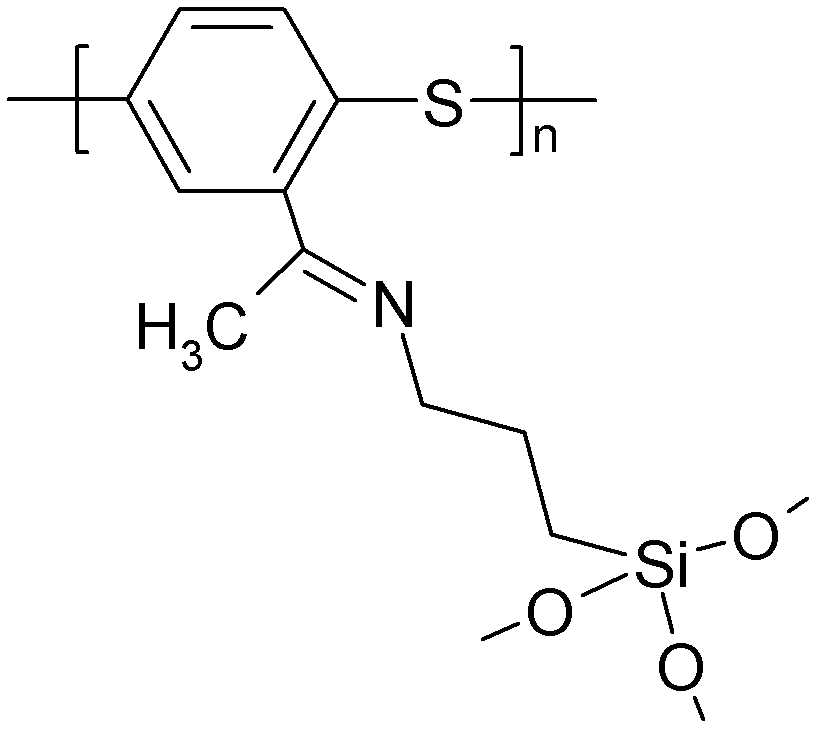

Organic silicon grafted and modified polyphenylene sulphide material and preparation method thereof

A polyphenylene sulfide and modified material technology, applied in the field of organosilicon grafted polyphenylene sulfide modified materials and their preparation, can solve the problems of increasing the rigidity of polymer chains, limiting the scope of application, poor impact toughness, etc. The effect of uniform grafting, simple operation process and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Under the protection of nitrogen, 20g of polyphenylene sulfide powder, 200ml of methylene chloride, 32.52g of anhydrous aluminum trichloride powder, 15ml of acetyl chloride, reacted in an ice-water bath for 1.5 hours, then heated up to 38°C, and reacted for 3.5 hours, cooled to room temperature, transferred all the reaction solution into glacial hydrochloric acid (50ml hydrochloric acid+50g ice) for decomposition, suction filtration, washing, and vacuum drying to obtain acetylated polyphenylene sulfide.

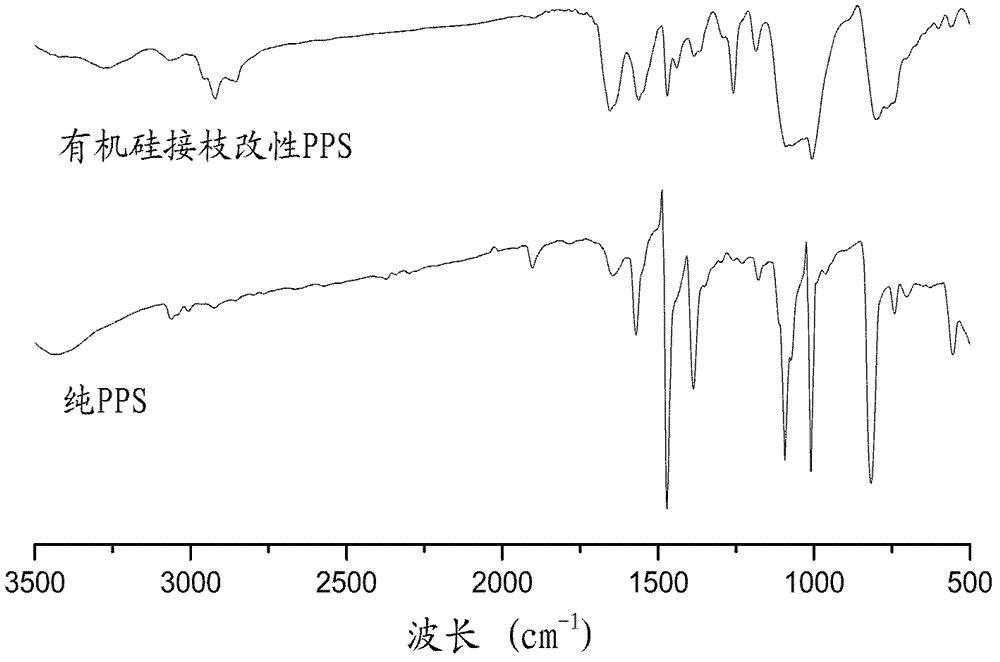

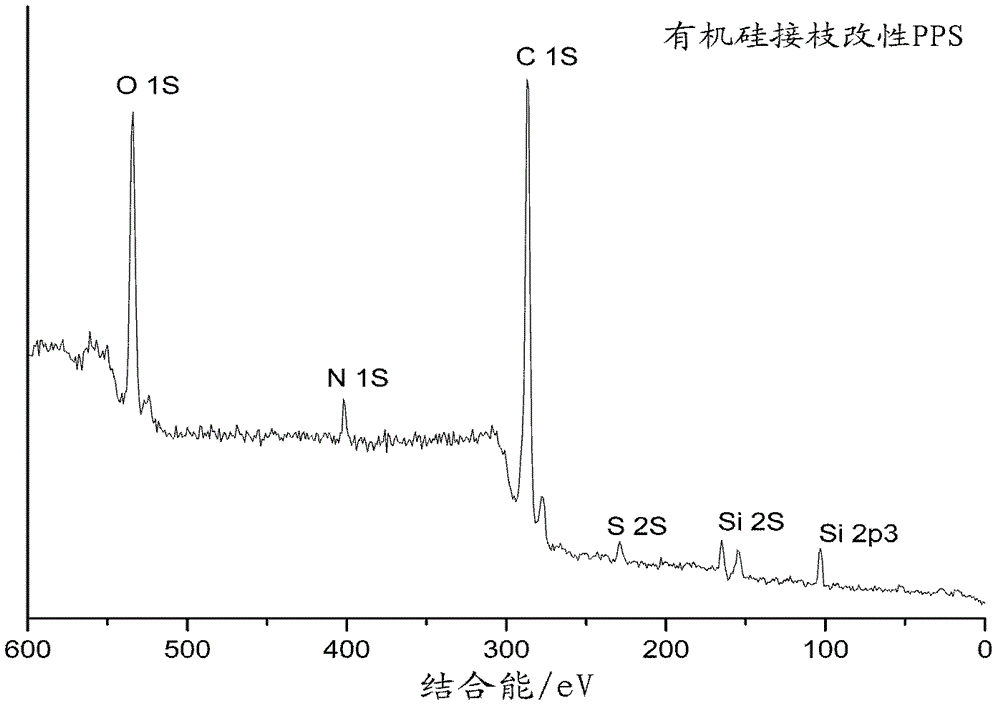

[0025] (2) Under nitrogen protection, 5.2g of acetylated polyphenylene sulfide powder, 100ml of toluene, 10ml of 3-aminopropyltriethoxysilane, 0.5ml of acetic acid, 2g of 4A molecular sieves were reacted at 80°C for 8 hours, Suction filtration, separation, Soxhlet extraction with ethanol solution for 24 hours, and vacuum drying to obtain polyphenylene sulfide powder modified by organosilicon grafting, with a grafting rate of 5.4%. The grafting rate is calculated by...

Embodiment 2

[0029] (1) Under nitrogen protection, 20g of polyphenylene sulfide powder, 200ml of methylene chloride, 16.26g of anhydrous aluminum trichloride powder, and 7.5ml of acetyl chloride were reacted in an ice-water bath for 1.5 hours, then heated to 38°C, and then After reacting for 3.5 hours, transfer all the reaction solution into glacial hydrochloric acid (50ml hydrochloric acid + 50g ice) for decomposition, suction filtration, washing, and vacuum drying to obtain acetylated polyphenylene sulfide.

[0030] (2) Under nitrogen protection, 5.2g of acetylated polyphenylene sulfide powder, 100ml of toluene, 10ml of 3-aminopropyltriethoxysilane, 0.5ml of acetic acid, 2g of 4A molecular sieves were reacted at 100°C for 2 hours, Suction filtration, separation, Soxhlet extraction with ethanol solution for 24 hours, and vacuum drying to obtain polyphenylene sulfide powder modified by organosilicon grafting, with a grafting rate of 3.4%.

Embodiment 3

[0032] In embodiment 1 (1), dichloromethane is changed into 1,2 dichloroethanes, and all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com