Preparation method of retarding and efficient water reducing agent for silicate cement and calcined gypsum

A high-efficiency water reducer and Portland cement technology, which is applied in the preparation of retarded high-efficiency water reducers, Portland cement, and calcined gypsum admixtures, can solve problems such as unsatisfactory product performance, and meet the production process conditions Easy to control, easy scale industrial production, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

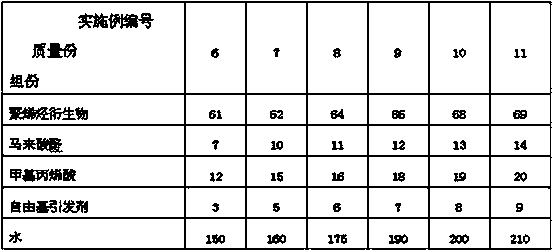

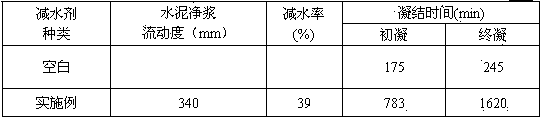

Examples

Embodiment 1

[0022] Take 70 parts by mass (the unit can be kilogram, the same below) of allyl polyoxyethylene ether-1200, 10 parts by mass of methacrylic acid, 10 parts by mass of maleic anhydride, and 2 parts by mass of ammonium persulfate into the reaction kettle , add 160 parts by mass of distilled water, stir and raise the temperature to 85°C, keep the temperature for 5h, after the reaction is completed, cool down to room temperature, add a pH alkaline regulator, adjust the reaction solution to neutral to obtain the product.

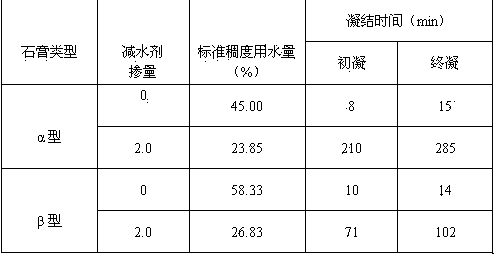

[0023] Gypsum Test:

[0024] The influence of the slow-setting superplasticizer synthesized in Example 1 above on the water consumption and setting time of the standard consistency of calcined gypsum was tested. Calcined gypsum adopts α-type gypsum and β-type gypsum. The gypsum is screened through a 200-mesh sieve and selected for testing according to GB / T17669.4-1999. The amount of superplasticizer (reduced solid content) is 2.0% of the mass of gypsum. The res...

Embodiment 2

[0034] A kind of preparation method of retarding superplasticizer for portland cement and calcined gypsum, comprises the following steps:

[0035] a. Take 60 parts by mass (the unit can be kilogram, the same hereafter) of polyolefin derivatives, 5 parts by mass of maleic anhydride, 10 parts by mass of methacrylic acid, and 2 parts by mass of free radical initiator, and put them into the reaction kettle, add 140 parts by mass Divide water, stir, and heat up to 60-90°C;

[0036] The polyolefin derivative is one or a mixture of allyl polyoxyethylene ether-1200 and allyl polyoxyethylene ether-2400;

[0037] The free radical initiator is one or a mixture of two or more of ammonium persulfate, potassium persulfate or sodium persulfate;

[0038] b. Keep the temperature at 60-90°C and react for 3 hours. After the reaction is completed, after cooling down to room temperature, use an alkaline pH regulator to adjust the pH of the material after the reaction to 6-8, and then a light yell...

Embodiment 3

[0040] A kind of preparation method of retarding superplasticizer for portland cement and calcined gypsum, comprises the following steps:

[0041] a. Take 70 parts by mass (the unit can be kilogram, the same hereafter) of polyolefin derivatives, 15 parts by mass of maleic anhydride, 20 parts by mass of methacrylic acid, and 10 parts by mass of free radical initiator, and put them into the reaction kettle, add 220 parts by mass Divide water, stir, and heat up to 60-90°C;

[0042] The polyolefin derivative is one or a mixture of allyl polyoxyethylene ether-1200 and allyl polyoxyethylene ether-2400;

[0043] The free radical initiator is one or a mixture of two or more of ammonium persulfate, potassium persulfate or sodium persulfate;

[0044] b. Keep the temperature at 60-90°C and react for 6 hours. After the reaction is completed, after cooling down to room temperature, use an alkaline pH regulator to adjust the pH of the material after the reaction to 6-8, and then a light ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com