ACR resin with excellent processing performance and applicable to PVC pipe fitting product

A technology of PVC pipe and processing performance, applied in the field of chemical synthesis, can solve the problems of butterfly spots, piebald spots, insufficient thermoelasticity, etc., and achieve the effects of excellent thermoelasticity, good dispersion, and excellent fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

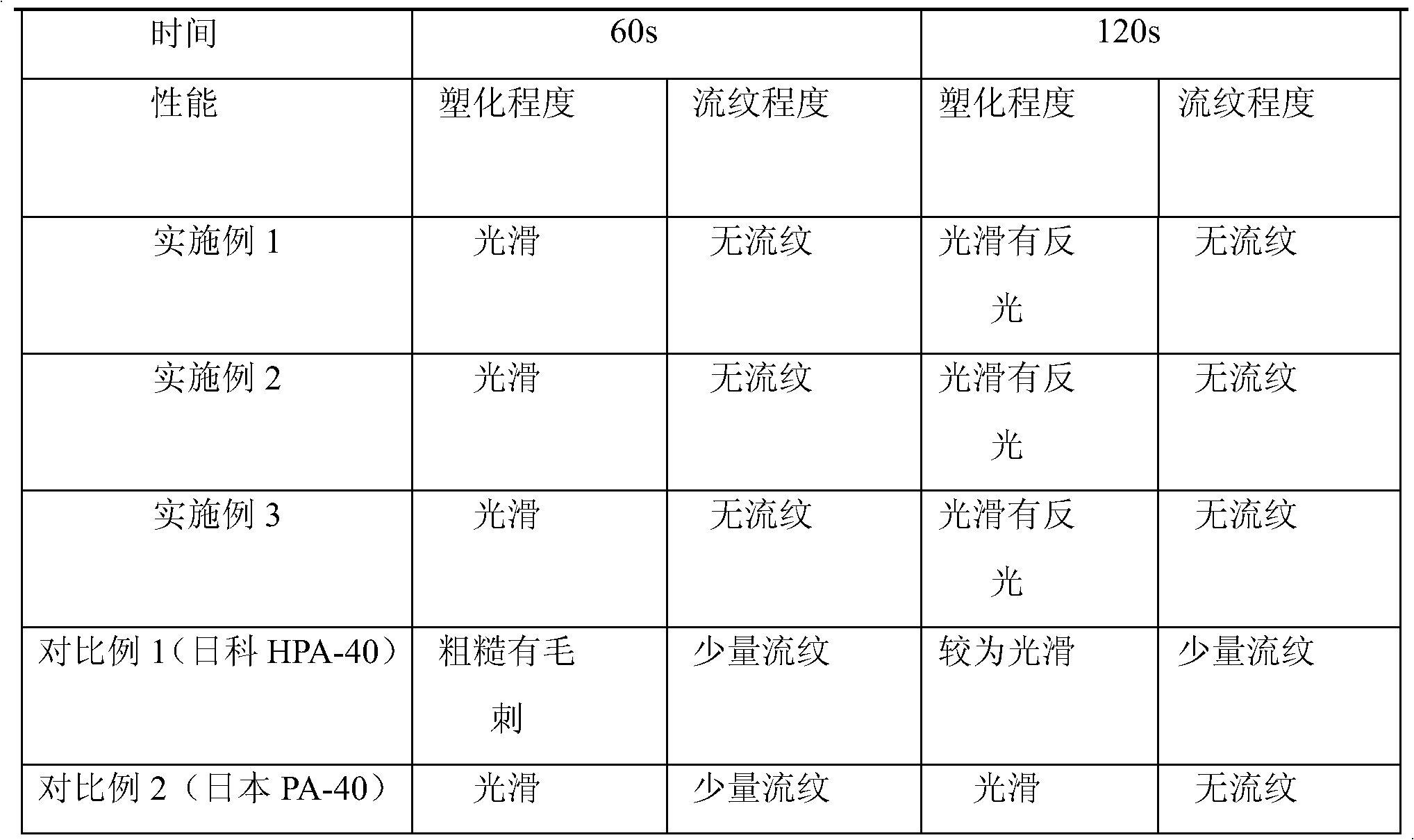

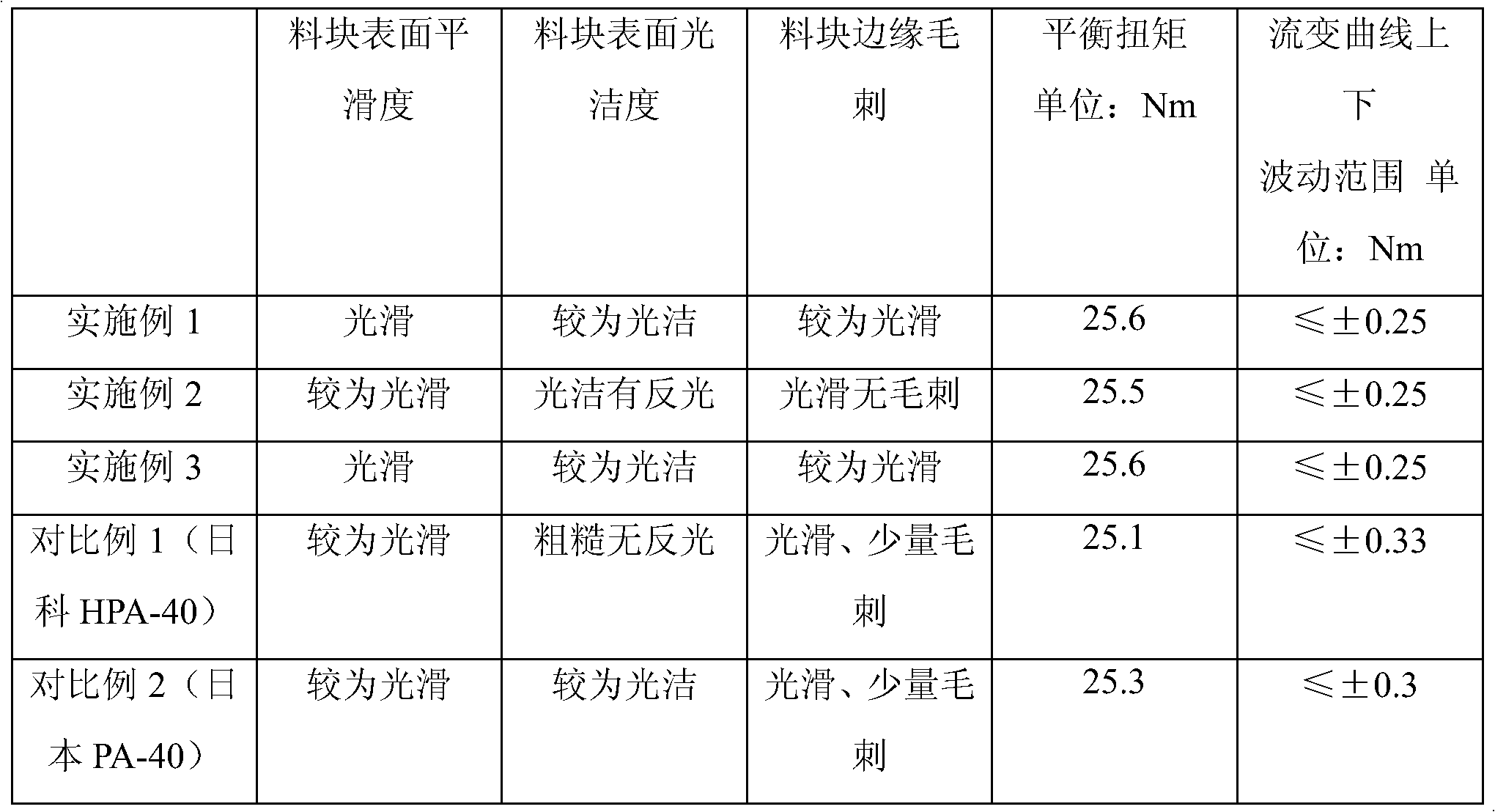

Examples

Embodiment 1~3

[0016] Embodiment 1~3 all reacts according to the following steps:

[0017] Add soft water of 100% to 150% of the total mass of polymerized monomers in the three-stage emulsion polymerization reaction to the glass-lined reactor, add the first-stage polymerized monomer methyl methacrylate, ethyl acrylate and the three-stage emulsion polymerization reaction 3-9% of the emulsifier of the total mass of the polymerized monomers in the medium is heated to 50-55°C, and an initiator accounting for 0.01-0.03% of the total mass of the polymerized monomers in the three-stage emulsion polymerization is added to initiate the emulsion polymerization. Protect, make it naturally polymerize and heat up, react for 1.5-2 hours, control the reaction temperature at 70-85°C, after the first stage of reaction is completed, add the second stage monomer ethyl methacrylate and butyl acrylate, react for 1-1.5 hours, Control the reaction temperature at 70-85°C. After the second-stage reaction is complete...

Embodiment 1

[0019] initial reaction

Embodiment 2

[0021] initial reaction

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com