Porous high-oil-absorption resin and preparation method thereof

A high-absorption and oil-absorbing technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as oily sewage and offshore oil spills, poor oil-water selectivity, low oil absorption ratio, etc., and meet the reaction conditions Not harsh, easy to handle, and the effect of improving the retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Accurately weigh 6g of OP-10 liquid, add 94g of water, and prepare an OP-10 solution with a mass fraction of 6%.

[0029] Add 0.0042g of N,N-methylenebisacrylamide, 0.0050g of sodium dodecylbenzenesulfonate and 2ml of OP-10 solution with a mass fraction of 6% and 1ml of water in a 50ml round bottom flask, and disperse by ultrasonic for 25min Then, 0.0054 g of azobisisobutyronitrile and 8 ml of lauryl methacrylate were added. The mixture was magnetically stirred and protected by nitrogen, and reacted at 70°C for 6 hours to obtain a spongy polymer product, which was washed with absolute ethanol and dried at 50°C to obtain a super oil-absorbing resin.

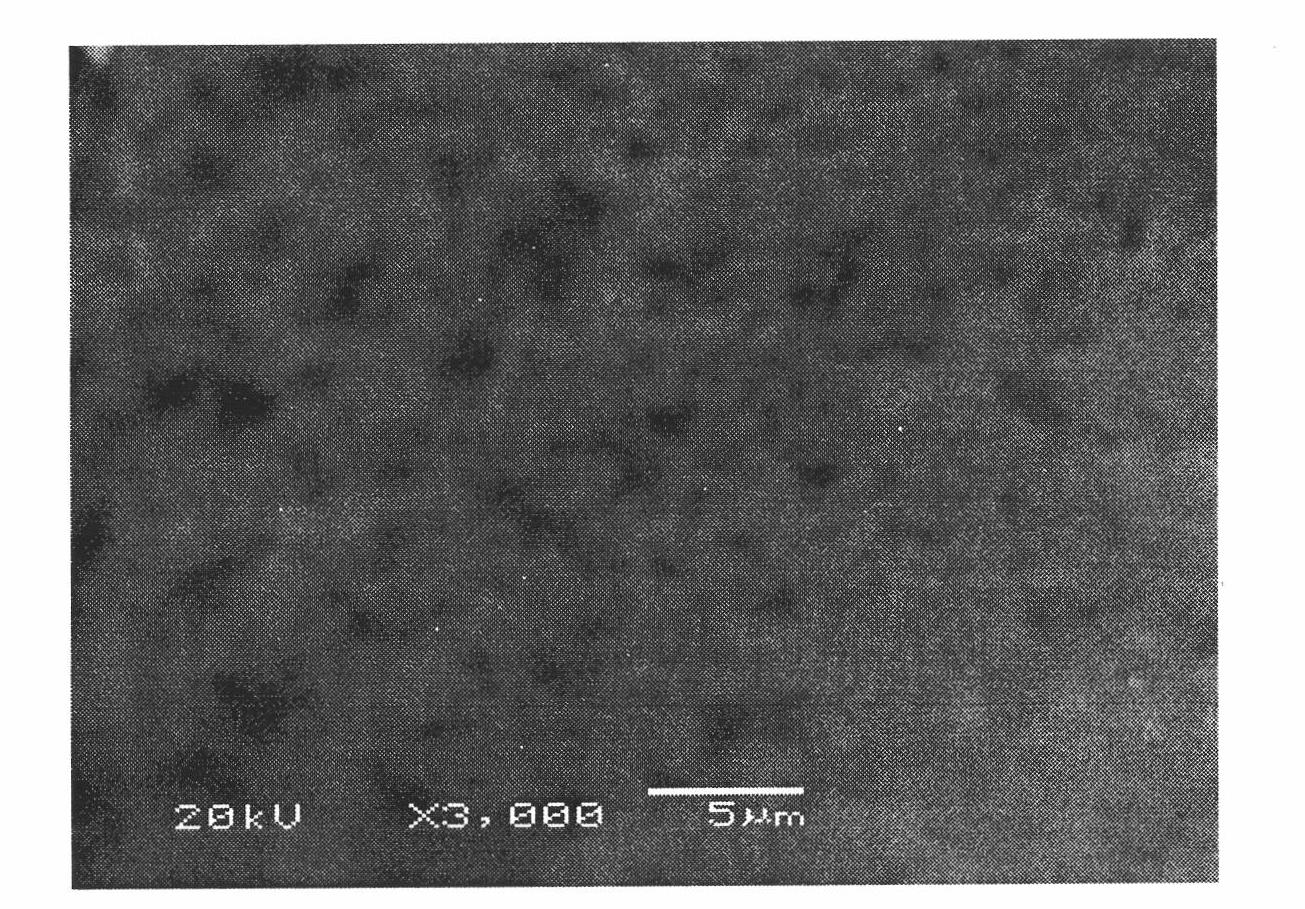

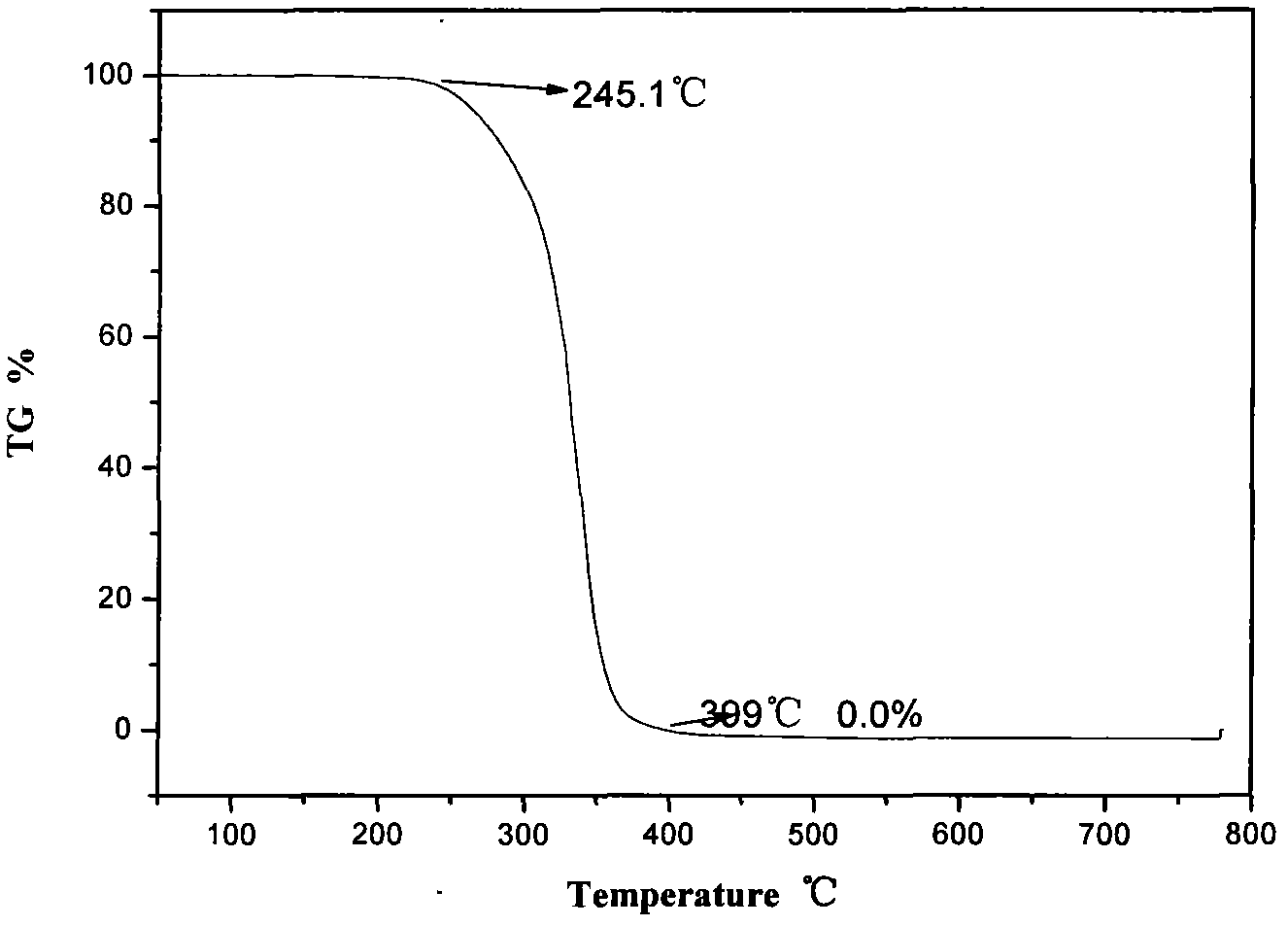

[0030] Characterization of porous superabsorbent grease

[0031] figure 1 Scanning electron micrograph of super oil-absorbing resin. Depend on figure 1 It can be seen from the scanning electron microscope image of the resin that the high oil-absorbing resin has a spatial network structure, the resin is similar to a spon...

Embodiment 2

[0036] Accurately weigh 5g of OP-10 liquid, add 95g of water, and prepare an OP-10 solution with a mass fraction of 5%.

[0037] Add N, N-methylenebisacrylamide 0.0042g, sodium dodecylbenzenesulfonate 0.0050g and 2ml OP-10 solution with a mass fraction of 5% and 1ml of water successively in a 50ml round bottom flask, appropriate amount of water, After ultrasonic dispersion for 25 minutes, 0.0070 g of azobisisobutyronitrile and 8 ml of lauryl methacrylate were added. The mixture was magnetically stirred and protected by nitrogen, and reacted at 70°C for 6 hours to obtain a spongy polymer product, which was washed with absolute ethanol and dried at 50°C to obtain a super oil-absorbing resin.

Embodiment 3

[0039] Accurately weigh 5g of OP-10 liquid, add 95g of water, and prepare an OP-10 solution with a mass fraction of 5%.

[0040]Add 0.0042g of N,N-methylenebisacrylamide, 0.0050g of sodium dodecylbenzenesulfonate and 2ml of OP-10 solution with a mass fraction of 5% and 1ml of water in a 50ml round bottom flask, and disperse by ultrasonic for 25min Then, 0.0054 g of azobisisobutyronitrile and 8 ml of lauryl methacrylate were added. The mixture was magnetically stirred and protected by nitrogen, and reacted at 70°C for 6 hours to obtain a spongy polymer product, which was washed with absolute ethanol and dried at 50°C to obtain a super oil-absorbing resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com